|

|

PDF

File(18k)

|

|

Picture of 1mm size HMG1

FractalBalls™

|

Macropicture of 3mm size

HMG1 FractalBalls™

|

Material

Safety Data Sheet

reviewed 2009

|

Product Specifications

(Nominal Only)

|

3mm |

5mm |

| Service Temperature °C (See FAQ's) |

1900 |

1900 |

| Density g/cm3 |

~ 1.1 |

~1.1 |

| Porosity, % |

~70 |

~70 |

| Surface Area(BET), cm2/g |

950 |

990 |

| Liquid (chemical) absorption, wt% |

50 |

50 |

| Water absorption characteristics |

Generally provided with Hydrophobic surfaces |

Chemical Composition

% Al2O3

% SiO2 (diverse forms)

not exceeding (mostly combined with alumina)

Impurities

Free silica |

~92

8

<0.5

nil* |

~92

8

<0.5

nil* |

| Loss on ignition |

0 |

0 |

| Cold Compression strength (N/mm2 or MPa) for each

individual ball |

- |

1 for 3mm

ball size |

| Linear shrinkage at service temperature 24h in % |

<1% |

<1% |

| Nominal thermal conductivity W/m, K 1200°C |

0.2 |

0.2 |

| Usual dimensions in mm (range) |

2-3.5 |

4-5 |

* Nil below detectable levels

Go to Price

List

FRACTALBALLS™

may be used as thermal insulation, chemical

substrates or as

structural materials when bonded

with FRACTALPASTE™.

These have multi-purpose use.

When bonded to each other they

are called Fractalins™.

- Use as thermal insulation:

FRACTALBALL™ has

very low density, low thermal conductivity, high strength, and high

melting point; it can be formed into any shape and size and be used

in any refractory/insulation parts for high and low temperature application.

- Use for high surface reactivity:

FRACTALBALLS™ have

very high porosity/low density, high strength, and high melting point.

They may be used for high temperature filter and membrane substrate

applications.

Typical Applications

are:

- Light

weight structure materials.

- Composite

manufacture reinforcement additive for metal, ceramic, or polymer.

- Armor,

bio-ceramic, abrasive brake pads etc.

- Coatings

for surfaces (metals, ceramics, polymers.)

- Thermal

insulation

- Fire

protection and stops

- High

temperature furnace linings

- Kiln

furniture

- Gas

combustion burners

- Repairing

or relining refractory cracks and holes

Other applications

are:

- Filter

- Molten

metal castings (aluminum, copper, iron)

- Steam

cleaning.

- Apply

as light weight coating for vehicles.

- Oil

trapping and recovery; grease filters; chemical and water purification

processes.

- Hot-gas

filter substrates for electrode.

- Electronic

substrate carriers for bioreactors.

- Desiccants

- Substrates

for catalytic converters

- Use

as light weight structural materials

-

FRACTALBALL™ has a unique microstructure,

very low density, high strength, and high hardness

What is the difference between FRACTALINS™ and FRACTALPASTE™

bonded FRACTALBALLS™?

The FRACTALIN™

material and the FRACTALPASTE™

bonded FRACTALBALLS™ are bulk materials

consisting of stacked/bonded FRACTALBALLS™.

However, because of differences in the manufacturing process, they display

slightly different properties as shown below. FRACTALINS™

are factory products shapes/boards made by a special joining process.

The FRACTALPASTE™

bonded FRACTALBALLS™,

on the other hand, are made into shapes/boards with the mixing and firing

of FRACTALBALLS™

and FRACTALPASTE™

by the user. (See section on how to bond FRACTALBALLS™

with FRACTALPASTE™).

The HMG1 material, of which the FRACTALBALLS™

are made, and the FRACTALPASTE™

material may be used up to temperatures in excess of 1850°C. All

trade marks on this document belong to MATTECH CORPORATION unless otherwise

stated.

FRACTALBALL™is

an unique lightweight, non-hollow porous ball with a very low density

and high strength. The material of the FRACTALBALLS™ (called HMG1) has excellent heat, chemical

and mechanical stability; the spheres have low thermal conductivity

and high thermal shock resistance. The spheres are sold in a fully fired

condition with excellent dimensional stability up to 1900°C. FRACTALBALLS™ are environmental-friendly materials: they

do not contain any hazardous materials such as organic volatents or

fibrous materials, and will not produce any smoke or odor when heated.

They also have desirable chemical, physical and mechanical properties,

such as inertness to chemical attack (solvents, acids, alkalies, and

detergents), non-wettability by molten metals such as aluminum, high

thermal stability, high strength, and micro-biological stability. These

features permit the FRACTALBALLS™to

be used in various applications.

FRACTALBALLS™,

which are made from the HMG1 material, may be used in loosely stacked

form or bonded into any size and shape part by bonding the FRACTALBALLS™ with FRACTALPASTE™.

These flexible processing possibilities allow FRACTALBALLS™ to be use in various technologies.

|

|

|

|

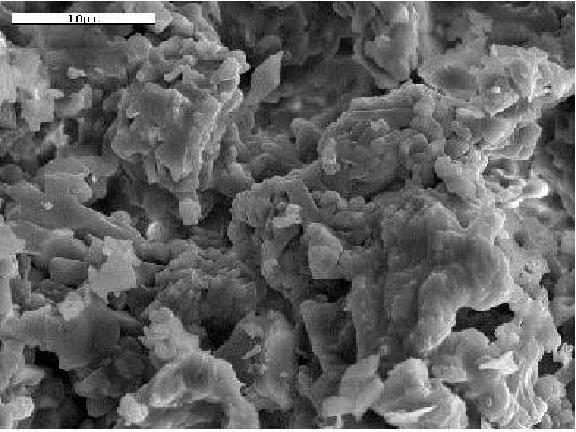

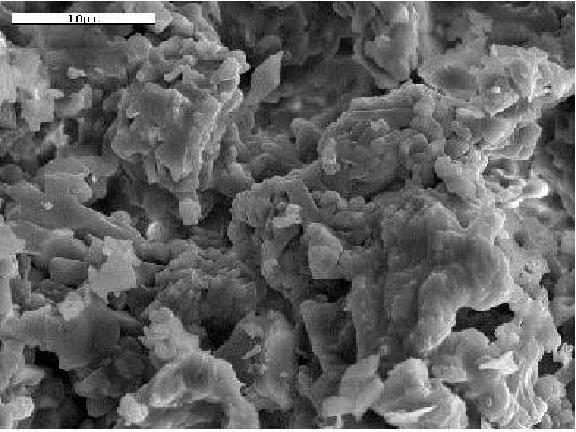

1mm Ball

|

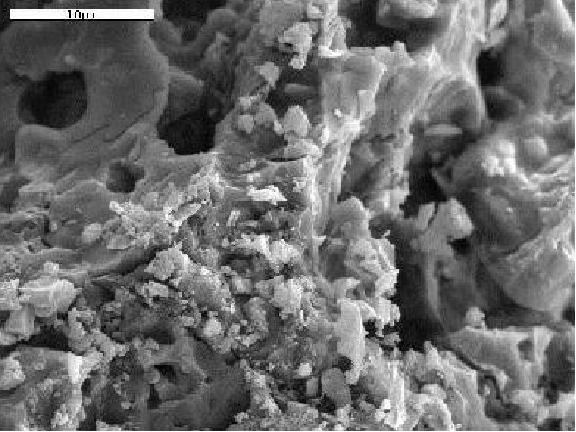

3mm Ball

|

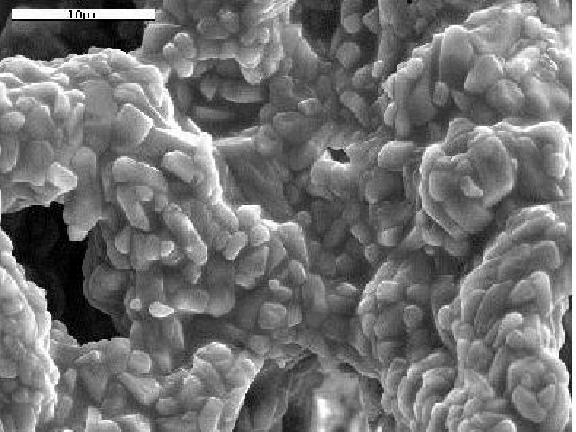

5mm Ball

|

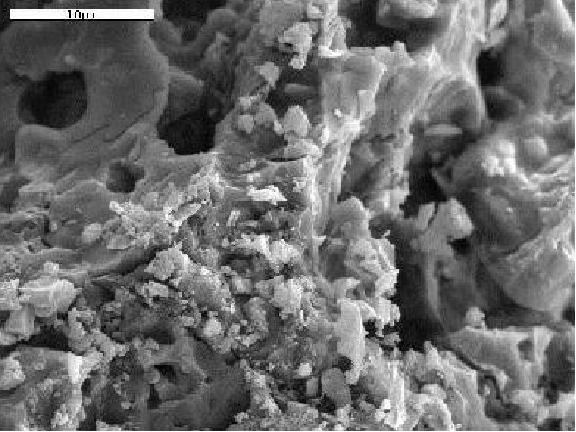

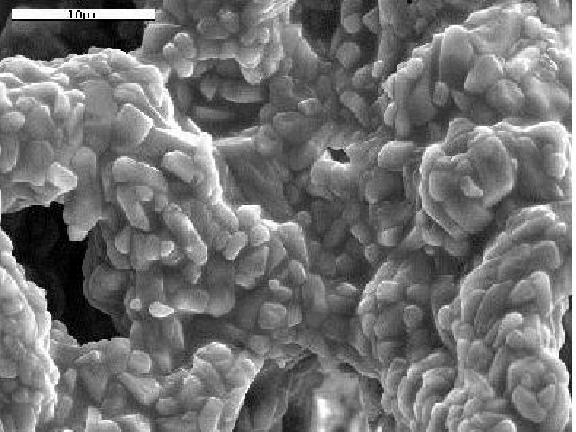

Surface Microstructure

of different size Fractalballs™. The micron marker is 10 microns.

Properties of Material

HMG1:

| Color: White |

| Nominal Composition,wt % |

| SiO2: (diverse forms) not exceeding 8% (mostly

combined with Alumina) |

| Al203: ~92% |

| Impurities: less than 1% |

| Ball Density, g/cc: ~1.1 |

| Stacked Density,g/cc: ~0.7 |

| Diameter,mm: (major range 1- 5 mm) |

| Maximum Use Temperature,°C: up

to1900° C Load carrying capacity diminishes after 1870°C.

(See FAQ's) |

Ball Porosity, % (average standard approximate): 70

(Can be made with higher porosity when required for custom orders) |

| Strength: Each 3mm ball supports approximately 10 kg of

Load. High Strength. |

FractalBalls™ have a porosity of about

70%; when loosely stacked the porosity is about 85%, FractalPaste™

bonded FractalBalls™have a porosity of 75%

whereas Fractalins™ have a porosity of about

80%. FractalBalls™glued with FractalPaste™ has a strength of 5 MPa whereas Fractalins™

have a strength of about 6 MPa. (Our data is approximate and changes

from batch to batch). Patents

Applied For and Pending. FRACTALBALLS™,

FRACTALINS™, FRACTALPASTE™,

FIBERFREE™, and FRACTALBALL™ are trademarks of MATTECH CORPORATION.

|