|

Issue 5 Vol. 4 February 19th, 2018

All of MHI's MicroheatersTM utilize patented NanoFractalAluminaTM and FractalinsTM materials, allowing for higher performance. To better understand which MicroheaterTM line is best for your application, feel free to give us a call at 513-772-0404 or contact us online

MHI Fiber Heaters may be used in both horizontal and vertical orientations. The Fiber Heaters are particularly useful for optical fiber processing, especially fiber coupler fabrication or tapering. For more information please give us a call at 513-772-0404 or contact us online.

Microheaters Applications

The objective of using free radiating devices is to maximize the radiative POWER transfer from the heating elements. If the heating element is covered with insulation, the objective of the user changes to obtain a certain temperature inside the insulated region. The control for temperature inside a chamber or power maximization in a free radiating mode can be made with MHI temperature and/or power controllers. For either objective, one cannot exceed the rated temperature of the heating element.

For obtaining maximum temperature MHI controls are highly recommended. Large diameter GAXP® microheaters could develop some springiness from induced magnetic forces. Potting in ceramic paste is allowed as long as care is taken to factor-in the loss of any thermocouple response in the measured temperature. Note element temperature will be higher and maximum element temperature should not be exceeded. In the free radiation mode the power can be maximized.

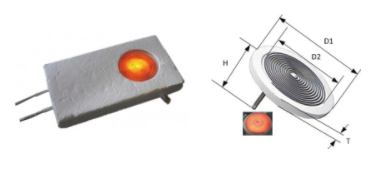

Versatile high temperature HeatPad™ is available in many sizes. Maximum plate surface depends on load. Non-reactive ceramic pocket type design allows for inserting, hanging, and positioning your HeatPad™ virtually anywhere. More...

|