|

(Click

here to search CI's Data Book.)

CI

Home

About

CI

Editorial

Archives

Current

Features

Calendar of

Events

Industry

News

What's

New

Classifieds

Advertiser

Index

Buyers'

Connections

E-Com

Profile

Online Show

Profile

Web

Showcase

CI

Giants

CI Giants

Listing Form

Components

Directory

Data Book

&

Buyers'

Guide

Equipment

Digest

Materials

Handbook

Refractories

Review

Reference

Government

Links

Industry

Links

Media

Kit

Subscribe

Online

Bulletin

Board

Contact

Us

|

Posted on:

11/01/2001

Processing Materials with Forced Air

Convection

By Dr. G.S.

Reddy, Research Associate, and Linda Amodeo, Assistant, Micropyretics

Heaters International Inc., Cincinnati, Ohio

Material

manufacturing involves several complex processing steps, many of

which use heat to accelerate drying, firing, sintering and other

operations. These processing steps are usually performed with gas

or oil-fired burners in kilns or other types of equipment that

often require a great deal of time and energy to operate.

A new forced air convection system* has been developed that can

provide a lower-cost, energy-efficient, more environmentally

friendly alternative for many material processing applications.

The new system uses a special class of heating elements to heat

ambient air, and the hot air is delivered through a host of

replaceable nozzles to perform the desired operation. The system

can achieve temperatures ranging from room temperature to 1400°C

(2552°F) with infinitely variable volume flow rates and no harmful

emissions, providing a beneficial new method for drying, firing,

sintering, melting, heat treating, and modifying the surface and

shape of ceramic and metallic

materials.

|

|

Convective vs. Radiative

Heating

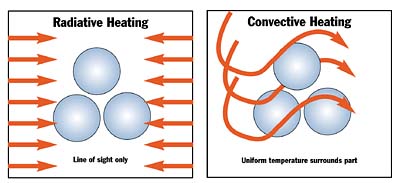

Figure 1. Simulated heat treating

uniformity. |

Unlike conventional

burners and heat sources, which typically use gas or other fuels

to heat the product through radiative, line-of-sight methods, the

forced air convection system is an electrical device that uses

molybdenum disilicide resistance heating elements as its heat

source. These elements, which are powered with anywhere from 0.5

kW to 60 kW of energy (depending on the application and required

temperature), are specially designed to deliver high temperature

under convective load heating conditions. Convective heating

ensures that the desired temperature uniformly surrounds the

materials or parts being processed, allowing heat treaters to

process parts faster with substantially less part failure caused

by non-uniform processing (see Figure 1).

|

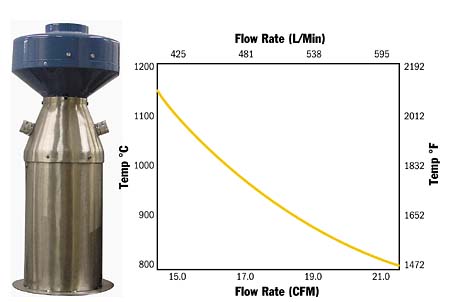

Figure 2. The higher temperature forced

air convection system with a plasma

stream. |

Additionally, because

the system is powered by electricity, it is up to 70% more

efficient than conventional gas-powered systems.

For applications below 1000°C (1832°F), such as drying,

preheating, curing and melting, the elements heat the ambient air.

A blower then directs the heated air through nozzles into the

processing chamber, heating it and the workload by forced

convection. The exit temperature of the air or inert gas is

controlled by adjusting the input of electric power or the gas

flow rate through the blower. The heating provided by the unit is

controllable from a very gentle convection to high-flow convection

by adjusting the blower speed.

For applications that require temperatures from 1000-1400°C,

such as sintering, curing, debonding, fusing and heat treating,

hot air convection systems are available that catalytically ionize

the hot air and emit an environmentally benign plasma stream (see

Figure 2). The plasma enables the system to reach higher

temperatures while still using uniform convective heating and air

or inert gas as the heating method.

|

|

Environmental Benefits

The air,

inert gas or plasma emitted by the forced air convection system is

pollution-free. Unlike flame-based technologies, which can cause

explosions, generate noise pollution and produce carbon soot and

other harmful emissions, the forced air convection system operates

silently and does not produce any harmful, pungent or contaminant

gases that could harm the user or the part being

heated.

|

|

User-Friendly Operation

Sophisticated

electronics, with features such as soft starting, programmable

heating and data acquisition, are integrated into the system to

make processing operations user-friendly.1

A lot of flexibility is also built into the system. For

instance, production engineers can use argon, compressed air,

steam, nitrogen or ambient air (using a blower) for the outlet

gas, depending on the application and atmosphere required.

Nozzles, too, can be customized to the end use application.

They can be obtained in different sizes and configurations for

operations such as plasma, bulk mass heating, drying and melting.

The system can be used as either an integral component of a

convection oven or a stand-alone heating device (in place of

conventional burners) in batch, conveyor or continuous pusher

furnaces. In many cases, the system can be used to augment a

conventional system, such as infrared radiation, that is already

in place. Additionally, because the forced air convection system

operates with a broad temperature range, a single unit can often

be used for multiple processing operations, such as drying,

sintering and firing, meaning that less operating space and

equipment are

required.

|

|

Factors Affecting Operation

Figure 3. Typical forced air convection

system with a blower mounted on top. The accompanying chart

is a temperature versus flow rate, indicating an inverse

relation. |

The forced air

convection system can be successfully used in almost any heat

treating application within the ambient-to-1400°C temperature

range (see sidebar). However, a number of factors influence the

system’s performance in demanding applications, including the

required volume flow rate, exit temperature, the angle of

incidence, nozzle design configurations and the velocity of the

hot air.

Volume flow rates and exit temperatures have an inverse

relation, as seen in Figure 3. As the required cubic feet per

minute (cfm) of flow increases, the temperature that can be

achieved by the system drops. For applications that require both a

high flow rate and high exit temperatures, multiple systems may be

needed. Three-phase systems, comprising three forced air

convection units operated with one controller, can provide an

efficient solution in these situations.

The heating rate depends on the direction of airflow (angle of

incidence). For optimum performance, the forced air convection

system should be installed at a 180°, 90° or 45° angle. Other

angles, including inverted, will also work.

The temperature of the exit air or gas also affects the speed

and success of the system. In general, the higher the temperature

of the exited air, the faster the materials or parts can be

processed. However, such temperatures are usually limited by the

materials’ or parts’ characteristics.

The nozzle configuration also affects the system’s operation by

affecting the velocity of the hot air delivered, which, in turn,

influences the rate of drying. In general, the higher the air

velocity, the faster the drying rate will be. However, as with

temperature, the application typically determines the required air

velocity.

|

|

Competitive Manufacturing

High energy

prices and the need to control production costs are making it

necessary for ceramic and glass manufacturers to re-evaluate their

operations. Equipment that was once considered essential in

thermal material processing operations must now be reconsidered in

light of new technologies. With an efficient heat transfer,

flexible and highly controllable operation, low equipment cost and

non-polluting operation, the new forced air convection system is

an alternative worth considering as manufacturers strive to remain

competitive in the global market.

|

|

SIDEBAR: Successful Applications of

Forced Air Convection

Figure A. A continuous kiln for drying

ceramic materials using the forced air convection system

coupled with

steam. |

Drying.

Improper

drying conditions often lead to the formation of blisters on

coatings and cracks on the product’s surface. In conventional

industrial drying systems, convection heating of the material is

limited by the heat transfer coefficient, hb, for the static

boundary layer between the moving air and the static liquid on the

surface. Infrared radiation, another type of commercial drying

technology, does not efficiently penetrate deeply into the

material because the waves are scattered by the particle system.

To prevent these problems, the forced air convection system

allows tight control of the volume flow rate of hot air for a

given drying temperature. This flexibility in fine-tuning the

system’s parameters helps the operator accurately and efficiently

control the drying process.

For accelerated drying, hot air from the forced air convection

system can be coupled with super-heated steam to permit safe,

efficient drying of sensitive materials over 100°C (see Figure A).

Because the specific heat capacity of steam (2010 J/Kg/°C) is

twice that of air at 100°C, the steam transfers more heat for the

same mass flow.1 Steam also promotes an increased

ability to percolate through a moist ceramic body, as the

viscosity of steam is approximately half that of air at the same

temperature, thus reducing the drying cycle. Hot air coupled with

steam will eliminate the moisture’s surface tension while reducing

its viscosity to half. The absence of surface tension helps the

surface moisture evaporate rapidly, while the lower viscosity

forces the internal moisture to migrate rapidly to the body

surface.

In contrast, the new forced air convection system promotes

higher velocity, reduces the thickness of the boundary layer, and

increases the transportation of heat and the apparent evaporation

rate. The rate of evaporation (RE) using the forced air convection

system can be expressed as:

RE = hb(TA-TL)/LE

where TA and TL are temperature of air and liquid,

respectively, and LE is the latent heat of evaporation. The new

forced air convection system operates at a higher air velocity and

produces higher (TA-TL) values, and both of these parameters

promote high evaporation rates, as seen from the equation.

While infrared emitters radiate heat that can be used for flat

surfaces with minimal losses due to reflection, infrared radiation

heats only those surfaces of the part that are in the line of

sight of the device.2 As a result, the part attains

non-uniform temperature, which, in turn, causes differential

expansion of thin film coatings and substrates. Combining the

forced air convection technology with infrared radiation heating

offers the advantage of heat convection, leading to uniform part

temperature even in deeply contoured and hidden surfaces of parts,

thus eliminating spalling and enhancing the drying rate as it

rapidly drives off moisture.

Sintering Hard Ceramics

The new forced air convection

technology can be coupled with continuous belt operation to

manufacture higher density silicon nitride machine tool inserts,

which can be used to machine extremely hard materials. Tests

revealed that the new system provided lower humidity and improved

uniform heating during the sintering operation, and these

characteristics yielded inserts with 3% higher density, maximum

shrinkage and no warping or micro-cracks. The increase in density

is believed to improve tool life.

Heat Treating Carbonaceous Materials

When used with

continuous belt operation, the forced air convection technology’s

cyclic “heating-cooling” type of loading has enabled it to be used

to dry or continuously treat the surface of fibrous, carbonaceous

materials in a host of heat loss environments. In conventional

flame-based systems, burning, oxidation and non-uniform heating

often occur, which adversely affect the integrity of the fibrous

material. Combining the new technology with steam for convective

heat transfer applications has made it possible to attain the

intended goals of drying and heat treating without adverse effects

due to the added ability to closely control and monitor the

temperature and flow rate.

Melting Alloy Ingots

The higher temperature plasma

forced air convection technology has been used to melt and cast

aluminum alloy ingots in a fireclay crucible with graphite wash.

The plasma acts as a protective or inert atmosphere over the melt

and prevents oxidation, resulting in cleaner alloy ingots. Ingots

made using the plasma technology had a bright shining surface, and

losses due to dross formation were less than 0.5%, compared to

furnace melted and cast ingots, which are generally 3%.

Shaping Composite Glass

Forced air convection

technology coupled with infrared heating can also be used for

shaping fiber reinforced composite glass in situations where

infrared heating alone is not sufficient. Glass shaped with this

technology has exhibited low residual stresses and higher impact

resistance, resulting in improved life.

References

1. Frank Sims, Engineering Formulas,

Industrial Press Inc., 1996, p.185.

2. Michael Grande,

“Combining Infrared & Convection Heating,” Process Heating,

September 2001, pp.

26-29.

|

References

1 K. Staples, V.

Sarvepalli, M. Fu and J.A. Sekhar, U.S. Patent No. 5,963,709, October 5,

1999.

Related

Websites

Dr.

G.S. Reddy has a Ph.D. in metallurgical engineering and is a research

associate with MHI Inc. He has over 10 years of industrial research and

development experience in metal processing. For more information about

the forced air convection system, contact Dr. Reddy at MHI, Inc., 613

Redna Terrace, Cincinnati, OH 45215; (513) 772-0404; fax (513) 672-3333;

e-mail [email protected]

or [email protected];

or visit www.mhi-inc.com.

|