|

Typical MHI

Furnace Features

Furnace Models

Please Contact MHI for detailed specifications on Standard Models

Micropyretics

Heaters International is recognized

as an industry leader in custom-built elements and furnaces.

Our design teams have the expertise to make true customization

possible, and we are able to build to your specifications from

the ground up.

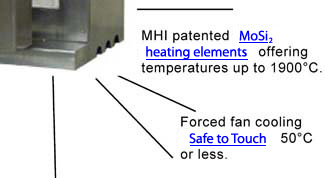

- Safety: Double walled Stainless Steel construction. This, along with the FiberFree™ refractory, allow for a safe

exterior working environment (~50°C or lower). Standard on many furnaces. MHI

furnaces, where applicable, have three-arm balanced swing away doors that keep

the hot surface side away from user.

- Warranty: Contact us to learn about the best warranty for your furnace

- High Temperature Furnace Classes: Almost all MHI furnaces

are lined with non-toxic FiberFree™ refractory in the furnace chamber.

FiberFree™ refractory is a safe-to-use insulation which does not contain any

toxic short fibers. Please check detailed specifications that are provided with

quote.

- Non-sag roof technology: MHI also uses the unique RHD

FiberFree™ refractory for the roof of most furnaces. This novel refractory does

not crack during cycling at operating temperatures which allows for longer life

of the furnace and longer life from the heating elements. Less cracks and longer

life means you will be running your furnace more efficiently and have an overall

savings (monetary, energy, replacement materials, etc.). This FiberFree™

material advantage is uniquely available from MHI!

- Robustness: MHI uses nanofractal roof hangers.

- Unique Hearth Designs: Several bottom loader type furnaces

now have floors that come standard with removable hearths. On large bottom

loader furnaces we have added a new design feature, which makes the already

sturdy door-top fully removable and lockable. If you ever damage the floor of

the door - simply change out this piece without incurring the larger cost for

the entire door. Hearths Platescan reach 2000°C operating temperatures with the

unique the non-toxic FiberFree™ refractory. Easy repacement through the MHI store.

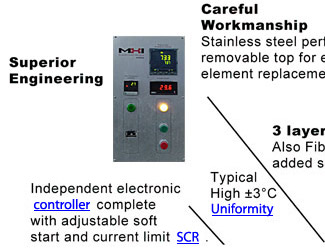

- Uniformity: As high as +/- 2°C temperature uniformity for small chambers. Slightly

more as the size increases. Uniformity is related to insulation quality and

quantity, furnace design, best heating elements and high class control systems

that for example are easily accepted in US governmnet laboratories. Overall care

matters when mating ceramics, thick gauge stainless steel and high temperature

heating elements. we often find the MHI provides an additional layer of

insulation compared to other manufacturers and provides the latest in feedback

control electronics.

- Our heating elements routinely outperform. MHI offers the

highest temperatures and longest life available in MoSi2 and GAXP heating elements.

- (Please see customer

testimonials for elements).

|

|

|

|

| MHI furnaces have eye bolts, swing away acces areas and ease of operation |

Multi-Tap Transformer for ease of operation at different locations

Easy connect terminals for better energy management and

cooler terminals |

Quality Mark

Unmatched high alumina roof hanger designs. Do not settle

for a furnace without roof hangers.

|

Versatile Controls and Data Acquisition.

X-PAN Control Panel

|

- Awards: MHI has received the prestigious R&D100 and other awards for its heating elements,

refractory materials, and furnaces. This shows our commitment to innovation and

continuous improvement so that you have the highest quality and best performing

furnace.

- Access to best practices and patented technology: We are a

completely integrated high temperature furnace manufacturer which allows us to respond quickly and efficiently to our customers' needs

worldwide. MHI has several service testimonials from satisfied

customers.

- Versatile: MHI furnaces are used in diverse applications

from chemical processing, vapor deposition, nano scale processing, materials

processing and energy conversion from R&D to prototypes to industrial scale

operations.

- Flexibility: When appropriate MHI takes significant care

in providing versatility. Mutitap transformers are often automatically provided when we understand that the

customer may move the furnace over time to a different location. In some

areas of the world there is a need for mutitap

transformers in order to cater for long-cycle voltage fluctuations. Regardless

it is very important for user to specify correct voltage at time of oredering.

See also:

MHI

manufactures novel devices when standard furnaces

cannot meet your needs. Please contact

us.

|

Customized

to meet your specific requirements. |

Our

customers continue to push the envelope of technology. MHI has

proven to the production and research communities that we can

provide the operation, uniformity, and performance necessary

to complete their requirements. As a technology leader, we are

constantly developing new devices to help the research and industry

meet their heat treating goals, from special element shapes,

customized continuous furnaces to our novel Zapper™.

If you have a unique requirement and need a custom solution,

please call on MHI to provide

the timely and accurate answer. |

|