Superheated Steam Generators|Microheaters | Airtorch®| Heating Elements | Radiative and Convective Heating Augmentation Heating Panels|Furnace and Furnace Accessories | Thermoplate| Microheater | Robust Radiator™ | Fiber Heater | Silicon Carbide Elements | Plasma |Nano Products | Electric Control Panels

Customer Quality Focus Example

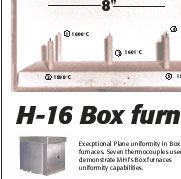

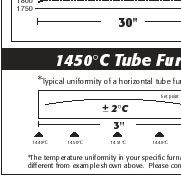

MHI furnaces offer a choice of efficient heating elements, fiberfree ™ safe refractory with high roughness emissivity, high eddy damping surfaces, double wall thick gauge stainless steel, modern electronics, and years of experience in manufacture – many patents protect the MHI Inc thermal systems. A few measurements of high temperature uniformity in MHI furnaces are shown below for different MHI products. The numbers will vary for specific furnaces and whether or not the steady state has been achieved. External reference ….”15 kW furnace with three PID-controlled zones. The uniformity inside a furnace can be influenced by thermals and wall or top-roof eddies (~1%) or asymmetric loads or eddies caused by the placement of roof holes and chimneys. Regardless, MHI furnaces are built to provide some of the best uniformities in the furnace sector.

Thermoplates can provide uniform temperatures of +/- 2 K over the length of the furnace at temperatures up to 1600 K.” Stanford University. MHI box and bottom-loading furnaces are among the highest in uniformity in their class. Typically, the uniformity across a plane depends on t/C positioning. At high temperatures, different t/c’s may measure slightly different temperatures. The Uniformity of a Thermoplate is very dependent on its use (coverage of the top) as it is an open radiator. Regardless, a ±2C is reported with the TLID option, but it is not guaranteed as several factors are in play. The values are obtained at steady-state conditions while minimizing convection. Keep in mind that with a TLID, the uniformity significantly improves.

The uniformity in MHI thermal devices is also because of the materials used and craftsmanship. This is particularly important for Thermoplates. The uniformity of Thermoplates depends on the matching of materials and close to zero expansion of several components.

Mightysteam® products like the OAB and GHGA produce dry steam with high uniformity.

MHI Airtorch® and process gas heaters provide a high temporal uniformity. See also a page on Energy savings and Uniformity with the Airtorch.

|  |  |

|  |  |

|  |  |

|  |  |