Steam Applications

Steam Plasma Applications

Steam Generator Models from MHI Learn about Steam Generation

Introduction

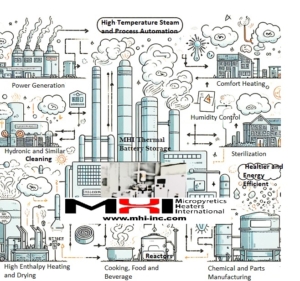

High-temperature steam is essential across various industries for its efficiency and versatility. This guide covers critical applica tions and benefits of high-temperature steam, focusing on the advantages of MHI’s MightySteam® and OAB® Electric Steam Generators, from comfort heating, energy generation, and biomass/fuels energy to antibacterial uses.

tions and benefits of high-temperature steam, focusing on the advantages of MHI’s MightySteam® and OAB® Electric Steam Generators, from comfort heating, energy generation, and biomass/fuels energy to antibacterial uses.

Critical Advantages of Electric High-Temperature Steam

- Superior Steam Generation Capability:

- Instant Start-up and shutdown (compared to days with fossil fuel boilers)

- Significant improvement in energy conversion to steam (compare 50% to 95%).

- Reduce the carbon footprint to zero for steam generation through deep decarbonization. Eliminate GHGs. Monitor load on the HMI display.

- Water Savings.

- There are readily available optimization choices for electric steam generators, such as variable flow rate, variable temperature, set pulse rate, and more.

- Superior Heat Transfer: Steam carries more heat than air or water, improving process efficiency. Electric steam generators offer up to 1200C instant steam for 100 kg/hr, an instant steam delivery method.

- Energy Efficiency: Electric steam generators convert energy with over 95% efficiency, unlike fossil fuel heaters, which have higher energy losses.

- Low Operational Costs: High-temperature steam is cost-effective, reducing energy consumption and improving process efficiency.

- Antimicrobial Properties: Dry, high-temperature steam is effective in sterilizing and disinfecting, and it is practical in the food, pharmaceutical, and healthcare industries.

- High Temperatures: Steam at high temperatures is better for many processes than boiler-produced saturated steam.

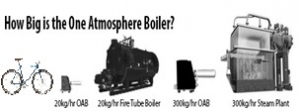

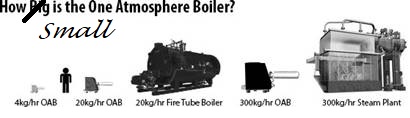

- Lightweight: Steam generators are lighter than boilers because they do not require Psat and Tsat coupling.

- Safety: Atmospheric steam generators are not prone to explosions. Distributed on-off steam generators can be employed to cut down on expensive and efficiency-reducing piping.

- The price of high-temperature steam equipment and operational costs are often much lower than those of fossil fuel steam boilers.

- Discharge steam can be used to cool water with steam jet cooling.

High-quality dry steam (compared to saturated steam from a typical pressure boiler) results in high productivity. Process speed and energy efficiency generally improve substantially with increased steam temperature.

Burner systems do not convert to heat energy as efficiently as electric heaters that operate well over 95% efficiency. Fossil fuel-burning heaters are low efficiency because heat is lost through the exhaust and several other radiative losses. To account for these losses, gas-fired heating systems are typically oversized for the heat demand duty. Start-up, turn-down, and shutdown are all processes that take time and reduce operational efficiency. In some cases, facilities will install multiple boilers at reduced capacity to compensate for the significant loss in efficiency at low loads. This is not the case for electric heating; the silicon-controlled rectifier (SCR) can respond to dynamic loads with a rapid heat response time and improve overall energy usage and efficiency.

High-temperature steam is used for R&D, Clean Pharmaceuticals, Food Security and Cleanliness, Oxidation, Process Chemical Applications, Pathogen Control, Climate Mitigation, Ore conversion (e.g., bauxite or lithium), and general-use utility steam applications. Low-pressure, high-temperature steam enhances safety in applications that previously required high-pressure boilers.

Is it time to move from inefficient boiler steam to modern energy-saving steam generators? Yes, because it saves energy, water, and time. It also offers flexibility and decoupling of temperature up from 100°C-1300°C, instant steam generation, and dial-in variability of the steam amount.

MightySteam® Products (Industrial and R&D Use)

MigthySteam® Controlled Humidity Products (Commercial Use)

Did you know it could be much less expensive to use clean methods? A decarbonized modern economy has low greenhouse gas emissions, mainly from its industrial sector. Energy decarbonization efforts in a nation involve changing the energy conversion/use system to prevent carbon emissions from entering the atmosphere. Electric heating methods allow for such decarbonization. Almost a third of the global CO2 emissions come from industrial combustion heating. CO2 emissions cause global warming. The rising surface seawater temperature influences global wind patterns. Changing surface winds, expansion of ocean water, acidification, heat waves, and the addition of melting Ice are responsible for rising sea levels. These emissions can be quickly reduced to zero CO2 and NOx emissions if industrial heating employs energy-efficient electric methods instead of fossil-fuel combustion. There is always a changeover cost, but the returns are more than attractive.

With the advent of new high-temperature high-quality dry steam, several enhanced designs and energy-efficient process applications have recently become possible. Steam is made instantly by the efficient MHI steam generators – the lowest-cost method for high-temperature steam. Attemp all manners of decarbonization with the modern MightySteam, Mighty Steam Plasma and Airtorch Units.

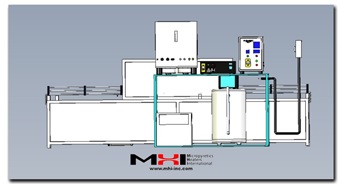

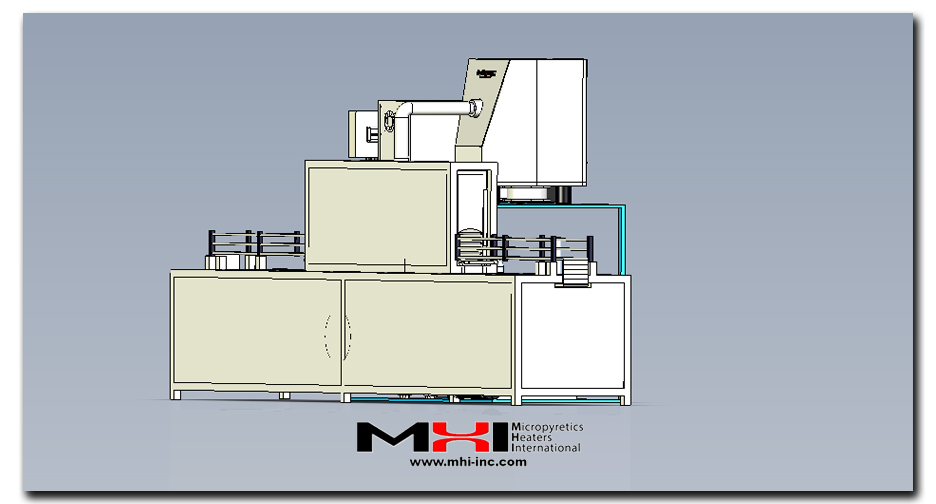

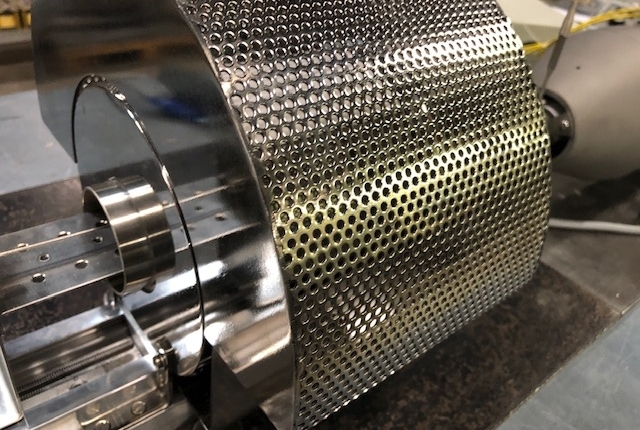

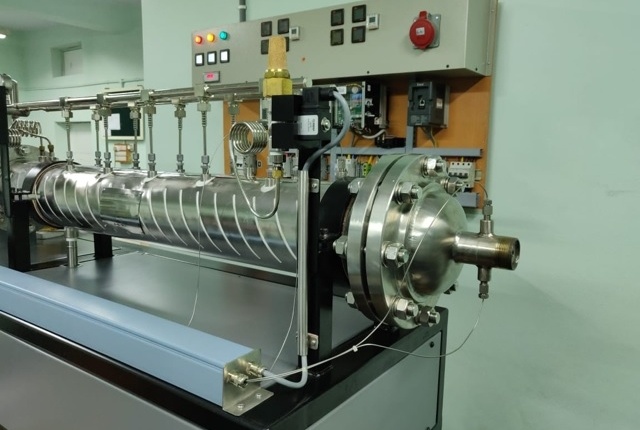

Modern electric steam generators (shown on the left) have replaced old-style pressure boilers and heat exchangers (shown on the right).

Steam generators can now efficiently produce high-quality steam. The MightySteam® and OAB® Electric Steam Generator products offer increased energy efficiency, lower greenhouse gas (GHG) emissions/pollutants, and decreased water use.

Compact, energy-efficient, versatile, and high productivity for clean steam.

Click here for a Brief Introduction to Steam and Humidity.

Click here for a Brief History of Steam Generators.

For Paint Removal (click here), use SanZiap -4 or HGA-M

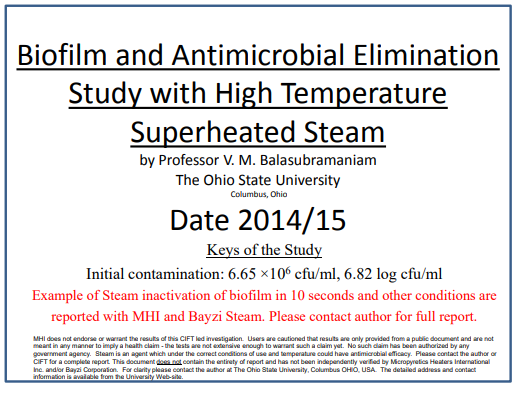

How powerful is steam? “The steam disinfection system rapidly killed various pathogenic microorganisms; all tested pathogens were completely inactivated within 5 seconds”. “American Journal of Infection Control). In contrast, spraying or fumigation disinfectant is not recommended (click). UV suffers from line-of-sight drawbacks and other radiation issues.

“We “are worried about using these (chemical) cleaners so often. The fumes and odors are terrible. I am worried about what we will discover about this exposure ten or twenty years from now….”. “medical Service Provider, Ohio, USA. Using steam generators that offer chemical-free steam above the inversion temperature is best.

The water activity (partial pressure of H2O) for food items containing bacteria is often high. Only very high-quality superheated steam should be used for rapid bacterial elimination. Superheated steam can quickly offer 3-log to higher efficacy within seconds. See Journal of Food Control, Vol. 125, 2021.

Examples where H2O is a process chemical:

Hydrogen is used to manufacture ammonia, acids, petrochemicals, and fuel (including fuel cells). The United States alone produces more than 10 million tons of hydrogen annually. The following examples are for steam reactions that are possible in hydrogen manufacture.

3Fe(s) + 4H2O(g) ⇔ Fe3O4(s) + 4H2(g)

From known thermodynamic tables, Kc at 500C for this reaction is 5.218E+002, which implies that plenty of H2 is made at this temperature, i.e., t; the forward reaction is favored. Concentrations of Fe and Fe3O4 are omitted when calculating Kp. Although the gas concentration can have various values depending on partial pressure, the concentration of a pure solid or a pure liquid is constant at a given temperature. The concentration of liquid solvent is usually omitted as well. For the reaction of iron with steam, you would write Kp=PH24/PH2O4 and get the PH2 value. The reaction 2Fe + 3H2O(g) = Fe2O3 + 3H2(g) does not go forward above 600C. The reaction Fe + H2O(g)= FeO + H2(g) is very weak by 1000C as is the 3Fe(s) + 4H2O(g) ⇔ Fe3O4(s) + 4H2(g) reaction. It is important to find the highest temperature where the reaction remains favorable and shows the best kinetics to make hydrogen with such reactions.

A more commonly employed reaction for making hydrogen is the methane steam reforming reaction (MSR), CH4 + 2H2O ⇔ CO2 + 4H2, for commercial bulk hydrogen production. Steam Reforming can be thought to occur in two steps, namely:

CH4 + H2O ⇔CO + 3H2 [ΔH = +206 kJ/mol]

CO + H2O ⇔ CO2 + H2 [ΔH = -41 kJ/mol]

________________________________________________

CH4 + 2H2O–> CO2 + 4H2 [ΔH = +165 kJ mol-1] is Endothermic, requiring high temperature for more significant and faster conversion. This reaction can be favorably manipulated with OAB(R) high-temperature steam.

Carbon or silica can react with high-temperature steam, which is sometimes used to produce hydrogen or other compounds and mixtures.

For example C(s) + H₂O(g) = CO(g) + H₂(g) AG= -17.6 kK/mol at 800C.

Steam/Water is an essential chemical in photosynthesis to make sugar or sugar-like compounds.

Although written in a simple reaction manner (6CO2 +6H2O > C6H12O6 + 6O2), the reaction is quite complex. This reaction, called photosynthesis, occurs in plants with the help of sunlight (photons) and uses chlorophyll in the plant cell chloroplasts. Chloroplasts are small molecular objects that have particular functions in a cell. Chloroplasts are found in plant cells and some other cellular organisms. During photosynthesis, chloroplasts capture photons and store the energy of the photons in the energy storage molecules ATP and NADPH, all the while releasing oxygen from water. They then use the ATP and NADPH to make organic molecules from carbon dioxide in the Calvin cycle. This cycle requires trapping sunlight energy during a part of the cycle. Ongoing e-ion and OAB research are directed at using photons and electrons to possibly simulate and aid the sugar synthesis or sequester the CO2. However, the research is at a very early stage.

Ongoing e-ion and OAB research are directed at using photons and electrons to possibly simulate and aid the sugar synthesis or sequester the CO2. However, the research is at a very early stage.

Use steam sterilization for:

- Culture media

- Flammable and heat-sensitive items

- Liquids

- Dense loads

- Cyclic steam bursts.

This page is helpful for personnel who identify with climate innovation, sustainability, decarbonization, clean energy, or are considered to be Circular Economy Specialists, Decarbonization Specialists, Energy Specialists, Climate Change Specialists, Energy Efficiency Engineers, Carbon Reduction Specialists, Clean Energy Specialists, or Sustainability Managers.

In a curious application where electrical heating of steam leads to better generation the pressure inlet into a turbine is nominally P=K(SQRT(G)) where P is the turbine inlet pressure (MPa g), G is the turbine inlet steam flow (tons/h), and K is a constant of 8–10. If steam pressure is raised without raising inlet temperature, the wetness fraction of the low-pressure (LP) turbine increases, which results in wetness loss increase at the Low-Pressure (LP) turbine. When wetness fraction of the LP turbine becomes 8%–12%, the countermeasure against drain erosion to the long blade of the LP turbine is required. In that case, it is more effective to simultaneously raise the inlet temperature together with the inlet pressure increase.

The MightySteam and OAB Electric Steam Generators do not produce greenhouse gases, such as CO2, Methane, or NOx.

Industrial Applications of MightySteam permit a wide range of standard and highly unique, high-productivity applications.

Chemical Processing

- Reactions: High-temperature steam is used in water-gas shift reactions and syngas production.

- Steam injection and mixing. Direct Steam Injection provides a highly effective solution for heating wastewater.

- Advantages: Improved reaction rates and energy efficiency. Higher temperatures, lower viscosity, and higher productivity

- Self-propagating (wicking).

Food Industry

- Processes: Cooking, drying, and sterilization.

- Benefits: Cleanliness at several levels enhances food safety and quality and reduces microbial contamination.

- Mixing with other fluids. Steam generators up to 1000 °C.

- Industrial Kettles and Vats: Use for steam heating of indirect and direct kettles. The high temperature OAB steam assures fast heat up rates without high pressure drop and related valves.

Power Generation Industry

- Use: High-temperature steam for instant start-up, improved temperature uniformity across parts of the turbine, and smoother steam-turbine spooling at high temperatures.

- Benefits: It may enhance turbine components’ product life from erosion, improve start-up and overall efficiencies, use instant steam augmentation, and enhance safe shut-down procedures.

- Benefits: It may enhance energy recovery for work and heat (recycle) components.

Pharmaceuticals

- Pure Steam Generation: Ensures sterile environments and equipment.

- Applications: Sterilization, clean room environments.

Textiles

- Drying: High-temperature steam improves the drying of fibers and yarns.

- Quality: Enhances the quality and efficiency of textile processing.

Air-conditioning

- Steam jet cooling of exhaust steam can make cool water for air conditioning and other purposes.

- From an OAB, all the exit water can be collected, but before collection, the steam can be used for steam jet cooling, making the COP just for that part of the process one or more.

- Quality: Enhances the quality and efficiency of both heating and cooling processes.

_________________________________________________________________________________________________

Air, water, and steam are three clean media commonly used to distribute heat to process loads. Steam made by MightySteam has several advantages, namely:

- The heat-carrying capacity of steam is much greater than that of air or water

- Steam provides its locomotive force at the steam front.

- Steam offers self-wicking possibilities.

- The electronic valve can be set for instantaneous cyclic use for on and off duration. This can be directly set on the touch-screen HMI.

- Steam gas provides efficient coverage and low viscous resistance.

- Steam is available at very high temperatures at a very low operational cost.

- Steam is a valuable compound in several vital reactions.

- Steam offers efficient drying above the inversion temperature.

Types of Steam and Applications

Steam Type Information Typical Applications Moisture Content Pure Steam Generated via stainless steel Pharmaceuticals, Hospitals 0% Dryer Steam High-temperature steam for sterility Sterilization, industrial cleaning < 3% Wet Steam Low-energy steam Car washing, other non-critical applications > 3% Superheated Steam Reduced heat loss Steam turbines 0% Low-Pressure Steam Efficient for specific codes Washers, laundrettes 0% Special Steam Used in chemical reactions Chemical and Petrochemical Industry – Culinary Steam Non-steam volatile agents Food industry 0% Comparison of Heating Methods

Heating Method Efficiency Maintenance Environmental Impact Application Areas Electric Steam up to 1200C 95-99% Low No direct emissions Industrial processes, sterilization Gas Boilers 80-90% Medium CO2, NOx emissions Large-scale heating, older facilities Oil Boilers 70-85% High CO2, particulate matter Industrial heating, remote areas Solar Heating Variable Unknown No emissions Supplemental heating, sustainability projects Heat Transfer Efficiency

- Thermal Conductivity: High-temperature steam has a thermal conductivity of approximately 0.022 W/m·K, allowing efficient heat transfer.

- Specific Heat Capacity: Steam’s specific heat capacity is about 2.08 kJ/kg·K, significantly higher than that of air, enhancing energy transfer in heating processes.

Pressure and Temperature Control

- Pressure Control: Modern steam generators like OAB® maintain precise pressure control up to 10 bar, ensuring consistent and reliable steam delivery.

- Temperature Stability: These generators maintain temperature stability within ±1°C, critical for sensitive industrial applications.

Environmental Impact

- Zero Emissions: Electric steam generators produce no direct CO2, NOx, or methane emissions, contributing to a cleaner environment.

- Energy Consumption: Advanced insulation and control systems in electric heaters reduce energy consumption by up to 30% compared to traditional systems.

Safety Features

- Overpressure Protection: Equipped with automatic overpressure relief valves to prevent system failures.

- Temperature Sensors: Integrated sensors monitor and control steam temperature, preventing overheating.

- Large scale highly efficient high temperature instantaneous steam

Applications of High-Temperature Steam

- Mixing and Fuel production

- R&D: Research and development applications in material science and engineering.

- Clean Pharmaceuticals: Ensures cleanliness in pharmaceutical manufacturing, which is critical for drug safety.

- Food Security: Enhances food safety and cleanliness, reducing risks of contamination.

- Pathogen Control: Effective in eliminating pathogens in healthcare and food processing.

- Climate Mitigation: Contributes to environmental sustainability through zero-emission heating solutions.

- Ore Conversion: Used to convert materials like bauxite or lithium in mining and metallurgy.

Why Choose MHI’s Modern Steam Generators?

- Energy Savings: Modern steam generators save energy, water, and time.

- Flexibility: Capable of instant steam generation and variable temperature control.

- Decarbonization: Supports efforts to reduce CO2 emissions from industrial heating.

Nomenclature for Modern Steam?

| Steam type | Information | Typical applications | Tolerance of moisture content |

| Pure Steam | Generation via stainless steel pure steam generator | The pharmaceutical industry, hospitals | 0% Dryer steam and High-Temperature steam aid sterility |

| Wet Steam | Can cause erosion in steam pipes | This is low-energy steam used for car washing and several noncritical applications. | > 3% |

| Saturated/high-pressure steam Utility Steam | The most used type of steam | Process heat < ~230°C, the typical inversion temperature. Food. | 0%, Available from Modern Steam Generator. Avoids any moisture. |

| Superheated steam | Reduced heat losses in the steam pipes. | Steam turbines | 0% |

| Low-Pressure Steam – depends on applicable codes and directive | When not subject to the Pressure Equipment Directive, favorable installation and operating conditions are the results. | The process heats up to 0.5 – 2 bar back pressure (depends on code) or is typically meant for continuous open discharge, e.g., washers or launderettes. | The highest electrical energy efficiency is with 0% moisture. Lower energy efficiency is obtained when droplets or poor-quality steam is present in the steam. Moisture represents condensation, a loss of energy, or it could represent a breeding ground for bacteria. |

| Special Steam for Chemical Processes and Fuel Production | Used in Chemical Reactions like water shift and Syngas. | Chemical and Petrochemical Industry Carbon Activation. | Up to 750°C and higher |

| Culinary Steam | Use of non-steam volatile dosing agents | Food industry | 0% Use high-temperature steam to 300°C |

| Anti-Microbial Cleaning Steam | Use for Multilevel steam cleaning for ultra-clean levels, From Grime, Paint Removal, or HealthySurface® | Food, Aircraft, transportation, Company-wide Cleaning, Ships, Containers, Trains, Disaster clean up. | 0% Use high-temperature steam to 300°C. |

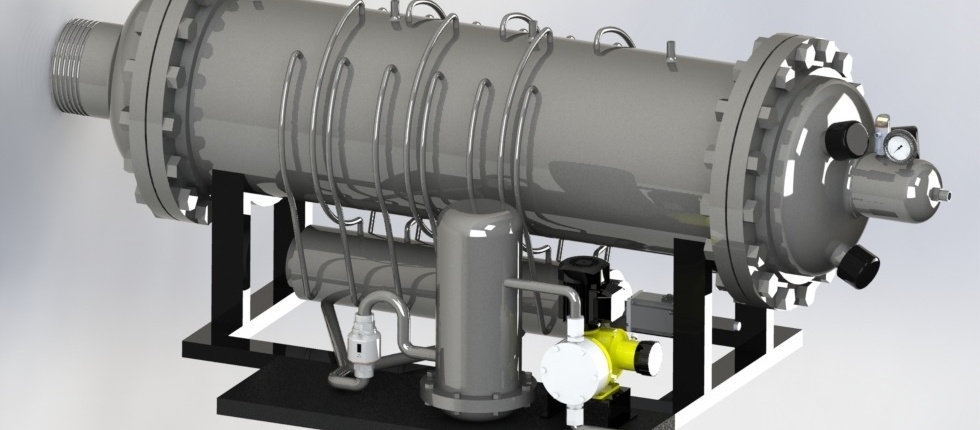

OAB

MHI steam generators are designed for low to high-temperature variable steam production for the highest temperature use. With this modern energy and time-saving steam generator, there is no need for superheaters or boilers to 800°C+ for high-quality clean steam. No combustible fuel oils or gases, No intense magnetic fields. No heating of flow pipes by induction. The temperature measured is that of the steam, not of the tube. Ask for MightSteam(® or Industrial OAB®.

Steam Generator Models from MHI can be used for all the following applications.

- Steam Drying: The capacity of the air (gas) stream to absorb and carry away moisture determines the drying rate and establishes the duration of the drying cycle. The two elements essential to this process are inlet air temperature and airflow rate. The higher the drying air temperature, the greater its vapor-holding capacity. Steam above the inversion temperature of ~180C dries surfaces faster than air—super quick drying with OAB steam. Since the temperature of the wet granules in a hot gas depends on the evaporation rate, the key to analyzing the drying process is psychrometry, defined as the study of the relationships between the material and energy balances of water vapor and air mixture.

- Steam reforming of methane, currently the primary route to methane conversion, can be represented as CH4(g) + H2O(g) = CO(g) + 3H2(g) Endothermic 2.06 x10^5 kJ/mol. Steam Reforming is feasible above ~750C. Methane (CH4) is the primary constituent of natural gas. With steam methane reforming and similar processes, the goal is to strip the hydrogen atoms from the single carbon atom, releasing the hydrogen for capturing. The carbon or carbon compound is a waste product with SMR. The primary reaction of SMR is as follows: CH4 + H2O ⇌ CO + 3 H2which is an endothermic reaction. An SMR reactor is at 800 – 900 °C to produce significant amounts of hydrogen.

- Ordinarily, 30-40 bar pressure may be required unless catalysts are used. Use high-temperature steam above 900°C or the steam plasma as the best catalyst. Blue and green hydrogen economies benefit when hybridization is considered.

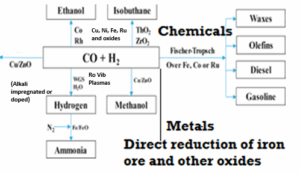

- The opposite-direction reaction to steam reforming is sometimes called the Fischer-Tropsch process. Selective liquid fuel formation is possible with the MHI Airtorch® or Insta-Steam Units. Contact MHI for details. Typical high-temperature steam, i.e., H2O(g), CO(g), and CO2(g) reactions for consideration for CO2 removal (one atmosphere) or for making H2 (gas).

- CO(g) + H2O(g) = CO2(g) + H2(g) Water Shift. Mildly exothermic.

- Combination of Greenhouse gases (also called high-temperature greenhouse gas reactions): CO2(g) + CH4(g) = 2CO(g) + 2H2(g) Feasible above ~650C or via the steam reforming and water shift shown above.

- 2CH4(g) + H2O(g) +CO2(g)= 3CO(g) + 5H2(g) Well feasible above ~(750-850C) with easy methods for enabling all forms of downstream reduction. MHI reaction. This highly endothermic process forms a synthesis gas that can be further processed into methanol and ammonia. The methanol-to-gasoline (MTG) process can then be utilized for gasoline production. Greenhouse gases such as methane can be converted to non-greenhouse gases, CO and H2. These reducing gases can be used for reducing some metal oxides. At this point, catalysts become essential. So, either the OAB® or Airtorch® may be used. Products that are reducing gases that can be used for various reducing reactions, including cleaning and polished metal production, such as Fe2O3 + 3CO(g) = 2Fe + 3CO2(g) (weak) or Fe2O3 + 3H2(g) = 2Fe + 3H2O(g) above 515C. Note also that CO2(g) + CH4(g)=2C + 2H2O(g) is always feasible at >100C but is extremely weak. Fe2O3 + 2CO(g) + H2(g) = 2Fe + 2CO2(g) + H2O(g) is always feasible but best above 1000C.

- Steam reactions at very high temperatures can be used for oxidizing and drying ores and concentrated metallic salt solutions like battery discharges and saturated pickling liquids (with Chlorides) (2M2Cl + H2O (made by the OAB(R))+ 0.5O2 (made by the Airtorch) = 2M2O + 2HCl). Reaction temperatures ~1060C.

- Note that several gases can be toxic; only professional involvement is recommended.

- What is MHI working on to help with global warming apart from its standard-proven approaches? Did you know MHI shares data openly when it is of public interest- of course, only whenever it is free to share? Please support us by purchasing MHI products. Interesting methods below – hint – look carefully at the reactions. Futuristic reactions. These are discussed only with MHI’s high-value existing partners. License possibilities to technology and trademarks. Contact MHI

2CH2O(g) + 2H2O(g) = CH3OH(l) + O2(g) above ~1320C Formaldehyde to Methanol

CO2(g) + 3H2(g) = CH3OH(l) + H2O(g) above ~1320C Methanol by heating Syngas or just CO2 (g)

Greenhouse gas CO2 can be converted to types of alcohol.

Waste to Fuel reactions can also be considered.

Waste to Energy with 850C steam. With Steam Plasma, many interesting steam reactions are possible above 1435C:

2C + 4H2O(g) = 2CH3OH(l) + O2(g) Carbon to Methanol (solid to liquid fuel type reaction with hot steam – (use Quasi-R® catalysts)

and Photosynthesis

6CO2(g) + 6H2O(g) = C6H12O6(Sugar -GAa) + 6O2(g) Yes negative free energy at MHI high temperatures. Call MHI.

- Plastics are hydrocarbons that are made from petroleum, and they can be converted back to liquid fuel. For example, pyrolysis could be used to do this. When subjected to high heat and pressure, water breaks down the plastic and converts it into oil. An attractive method of converting these waste materials to useful form is anaerobic digestion with steam heating which gives biogas that can be used as a fuel. Waste can also be converted to methanol and ethanol. Garbage can be converted with plasma impact to break down organic materials into syngas, a hydrogen and carbon monoxide mixture. Organic waste via the Fischer-Tropsch reaction can be converted into fuel. A mixture of hydrogen and carbon monoxide – from municipal solid waste and other renewable biomass can be converted to long-chain hydrocarbon molecules that make up diesel and jet fuels. Some of these reactions are discussed below.

- Do you plan to eliminate fossil fuels by using hydrogen from electricity generated by steam power? Did you know electric steam systems are much simpler than combustion fuel-use boilers? Steam-use processing companies worldwide are feeling pressure to lower the environmental impact of their operations and make them more sustainable. These pressures come from governmental regulations and societal expectations, resulting in increasingly stringent requirements expanding globally. Many companies are accelerating their “green” initiatives and programs to leap ahead of these regulations and lead this transformation for their industry. MHI Airtorch® and MightySteam® can assist your various initiatives.

Comparison of Steam Generation Methods Boilers and Steam Generators

- MHI offers CO2 (carbon dioxide) and CH4 (methane gas) Airtorch® heaters. Please see the reactions below for syngas and choose the most suitable GHGA model. Please contact MHI for each.

- To help with COVID-19, we encourage our customers to support front-line workers at hospitals, testing clinics, and other healthcare facilities to fight against the coronavirus and the COVID-19 disease it causes with innovative uses of steam products and Airtorch® Products. We have placed many such products in the ‘Sale’ section of the MHI web store.

- Antimicrobial Applications: Dry high-quality low-oxygen steam is a known antimicrobial agent without organic residue. The canning and bottling industry uses a considerable amount of steam. Use for aseptic processing. The productivity increase with the availability of MightySteam™ – high temperature, dry, and instant is a remarkable condition for steam – beneficial for cleaning and soil remediation.

- Please click for antimicrobial steam tutorials and published studies.

- Use HGA-S, HGA-M, or MightySteam® for most 1-4 kg/hr cleaning applications.

- Heating Applications: Steam offers heat transfer coefficients that are very high. The heat content is also very high. Steam dries faster than the air above the inversion point. Use one of these generators.

- Why is superheated steam far superior to saturated steam? Why is it better at eliminating microbes when above the inversion temperature?

- Many bacteria and even viruses thrive in water. Saturated steam can easily contain water droplets promoting microbe multiplication and retention. Entropy 2021, 23, 181. https://doi.org/10.3390/e23020181. Superheated steam does not have water droplets. Above the inversion temperature, the heat transfer characteristics are great for penetration when using superheated steam, particularly above the inversion temperature. This is particularly important for moist food.

- Superheated steam deep cleans within seconds. See the recent article in Food Control 125 (2021) 107942.

- Click here for Nano-Catalyst and Bacterial Clean Metallic Coupons

- Pasteurize Milk.

- Are you still using chemicals? Antibiotic resistance poses a significant threat to public health. Take action sh sanitizers are causing problems. Published articles Take action now.

- Unusual Properties of high-quality Steam-Gas:

- Penetration: Steam, as it condenses, continues to wick. Use one of these generators.

- Additive: Add to Gas or Plasma Streams. Use one of these generators.

- The heat content is very high.

- Steam dries faster than the air above the inversion point. Use one of these generators.

- Low-Pressure Steam: Check out the options. OAB® Other Suggested Applications.

- Steam is Antimicrobial (Bacteria, fungi, or Viruses) depending on the temperature and residence time. Click here.

- For Zero CO2 use:

- Zero CO2 production cyclic reactions. Please see below.

- Power Generation with Steam. MHI steam 800°C+ models for Mega Watts help turn turbines. Remember, only the temperature difference is related to the Carnot efficiency. Please contact MHI.

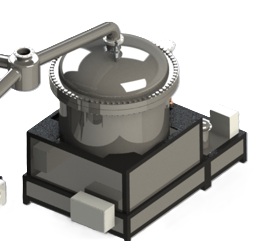

Why use an autoclave when modern steam can be obtained instantly and without pressure at the correct high temperature?

Why use an autoclave when modern steam can be obtained instantly and without pressure at the correct high temperature?

Bring your designs to life with beautiful colors and creative shapes. Become a high-quality-steam user.

Why use an autoclave if your need is high-temperature steam? Creating pressure and releasing pressure is a huge waste of energy.

Calculate the energy used in pressurization/vacuum and compare it with the OAB® and HGA steam. Compare the footprint of traditional steam boilers with the OAB®.

Mobile units for heavy-duty sanitation and other types of cleaning

or Industrial Size but so much more compact than a boiler.

Versatile Steam Generator

Commonly Asked Question: Does one need high pressures or a vacuum for steam to penetrate textiles or cloth packs? Answer: Most often, no – provided the steam is super-heated adequately.

Steam self-propels as a gas. Use this unlimited capacity of propagation from continuous steam generators.

Typical uses of clean steam are in pharmaceutical and biopharmaceutical manufacturing, sterile manufacturing, sterile comfort heating, and injection of high-purity water.

Graphical data of the COVID-19 virus for every country.

when used for the correct residence time and temperature, steam is an antimicrobial agent

Listeria monocytogenes Pseudomonas aeruginosa

Eschericia coli (various types) Salmonella typhimurium

Salmonella enteritidis Streptococcus faecalis

Staphylococcus aereus (Resistant strain) Legionella pneumophila

Bacillus subtilis Viibrio parahaemolyticus

Enterobacter aerogenes Bacillus cereus

Can steam kill (deactivate) the Coronavirus? It appears so based on the temperature and residence time requirements. As with all antimicrobial uses, each condition could be different, and testing is required for efficiency analyses. When cleaning surfaces, particularly metallic, please use the steam residence for >280C and adequate residence time. The residence time is a time of use; any steam-based killing may require at least a few seconds of proper use, like about ~20s for handwashing with soap. The higher the temperature, the higher the probability of killing. The higher the residence time, the higher the chance of killing.

Some metallic nano-surfaces can also deactivate bacteria. Test coupons are available.

Videos and Media Gallery for Steam

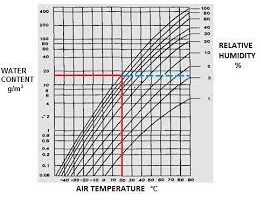

Humidity Calculation: The psychometric chart plots the same graph’s temperature, relative humidity, and water content. For example, find the water content in grams of 1 m³ of air at 20°C and 60%RH. To determine this value, we need the Psychometric Chart of Humid Air. For simplicity, we start from the horizontal axis (air temperature) and look for 20°C (point A). From point A, we raise vertically, reaching the intersection with the curve at 60%RH (point B). The answer is on the correspondent point on the vertical axis (point C), approximately 12 g/m³. Therefore, one m³ of air at 20°C and 60%RH contains 12 g of water vapor. Finally, to determine the dewpoint in the same conditions, follow the intersection of the 100%RH down vertically to point D. In this case, the dewpoint is approximately 10°C.

Superheated High-Q Steam Generators – 1kW | Superheated 1KW Steam Air Mix Generator

High-Efficiency Steam Recirculating Ovens|

Typical Superheated Steam Applications are Drying, Antimicrobial, Steam-heating, Fuel Production, Batteries, and Chemical Reactions.

Improve productivity with steam – use a temperature higher than the inversion temperature—Deepwater and energy savings.

Industrial Sector | Products |

| Biomass (for electricity generation) Waste to Fuel (see below) Product Recovery Materials Recovery. | Sawdust, wood fiber, pulverized coal, wood chips, wood pulp, spruce and birch bark, milled peat, peat for briquettes, Fuel from Waste, and Municipal and plant waste. Recycle CO2 by using hot steam in a fuel cell to make hydrogen and then use the Airtorch® for hydrogen reaction with CO2. So first, water vapor breaks down into hydrogen and oxygen -electrolysis at 800C – then use the H2 (g) with CO2 (g) – see reactions below. Burning Fuel gives CO2(g), so the cycle can be completed. Energy use is also seen in electrochemical power generation with two-phase raw materials. Decarbonizing the industrial sector is critical to addressing our climate crisis. Recycle battery materials and batteries. |

| Chemical industry | Washing powder, pigment, potassium salt, fine chemicals, catalysts, coloring agents, regeneration (chemical), carbon activation. It is recognized that the process for turning rubber compounds into usable finished products is vulcanization. There are various types of vulcanization. The most economical is open vulcanization, which can occur in hot air or steam. In the past, proper hot steam and high-life hot air were unavailable. It now has patented MHI products that accurately offer a wide variety of steam, hot air, and hot process gasses. Units with extremely high warranties have changed this landscape. This will help make synthetic diesel from water, electricity, and CO2. |

| Food industry (sugar) | Sugar beet pulp, dietary fiber from sugar beat.

|

| Food industry (base materials) | Hog fuel, corn fibers/fibers, protein-containing base materials (soybeans, rapeseed, sunflower seed, soy meal, okra, etc.). Peel vegetables like potatoes, tomatoes, dry vegetables, essential oils, and organic compounds. Fuel from waste food is offered above 750 C.

|

| Food industry crimp | Shrimp, pork, bamboo shoot, paddy/rice, herbs, cacao beans, corn gluten, tobacco (drying, expansion). From cooking to cleaning. |

| Food industry (starch) | Starch, potato, vegetable, wheat flour, distillers grain, and other staples. From cooking to cleaning. It is reportedly much better than vacuum drying, flavors, vat heating, and scents. |

| Food industry (meat) | Pork, bone meal. Clean meat tables and study tables. Food laboratory. Review Applications. Canning, Bottling, and Packaging Improve productivity and efficacy. Potatoes, Mussels, and artichokes can be Steamed, as can Rice with MHI steam products. |

| Epoxy. Mold, Castings, Cast Iron | They are curing and drying. Polymer curing, reactions, coagulation. Drying of sand molds and investment molds. Steam Chest Molding. Heat Staking. Foundry molds, Metal heat treating. Surface treatments by steam. Seam press vinyl and fabric |

| Chemical processing reaction | Reaction kinetics manipulation, water-shift, WGSR reverse water gas shift reaction, flavor reactions, photosynthesis, azeotropic distillation, volatile(s) manipulation, and rubber vulcanization. |

| Paper & pulp applications paper | Paper, fiber/fiber sludge from wastewater treatment, drying |

| Textile applications | (Coated) textile, drying, cotton fibers, improve water uptake, enhance the quality of fiber yarn for cotton waste |

| Waste materials industrial | Industrial wastes, filter cakes, sludge from water purification, municipal sludge |

| Vegetables & fruit vegetables | Vegetables, Tea, Coffee, and herbs daily |

| Dairy industry milk | Milk powder, flash drying |

| Potato | Potato products, fries (pre-drying) |

| Metal Finishing | For antimicrobial and other cleaning/finishing metals, semiconductors, silicone/plastics, rubber, composites, and ceramics. |

| Building materials such as wood | Wood, lime mud (before calcination), paint, adhesive, mineral wool, fibers, lumber, cement curing, Shrinkwrap packaging, quick energy-efficient use. Green Pipe Repair. |

| Laundry industry/ General to unique cleaning laundry laundry | Laundry, dry cleaning, cleaning (several levels including microbial). Clean bio-implants and textiles. |

| Textile fiber enhancement improvement | Improved torsion strength of the fiber |

| HVAC cleaning Medical Catheter | Please click on cleaning |

Steam Tunnels

~90% energy and water conservation, even for the most complex-shaped glass bottles.

For a more detailed answer……please inquire here about pack penetration.

Calculations of Savings from Smart Lower Power Consumption Technologies.

Efficient steam tunnels for packaging, shrink wrap, antimicrobial, and textile.

Plug-n-Play to Vats

Chambers for steam testing, reaction analysis and oxidation tests

Steam Testing Chambers for Oxidation, Testing Steam reactions and Steaming Efficacy Results

Rapid Packaging With Energy Benefits

Food and Brewery Industry.

BPE/CPG

Textile Applications with Smart Steam

Innovate, take the smart risk to save energy.

Food Safety

Want to find out how MHI can help you meet your steam needs?

Please fill out a quick questionnaire by clicking on the product of interest.

We will help find a good solution to meet your needs.

Steam For Fuel From Waste

Waste to Fuel with MHI Products

Use of Syngas – tunable manufacture with MHI Products.

Extremely high yields. Impact the environment with MHI Products.

Productivity vs. Temperature PDF

Design with GHGA or OAB® Steam and Hybrid Tunnels. THE GHGA can provide high-temperature steam up to 900C (can be set as required), pressure can be automatically adjusted, and steam rate can be changed.

Tunnel Design from the High-Temperature Leader

for Shrink-Wrap, Clean for Removing Bacteria or Condition Cotton Textiles

Feeding into SWE machine. Adding moisture to cotton fiber or shrink-wrap CPG.

Cotton fibers improve their integrity with moisture. The SWE machine with the steam tunnel is easily able to do this.

Save electrical usage. Paying 25¢ per bottle? Check out if the OAB steam tunnel can reduce to 2¢.

| Compare the OAB to: | |

| Fire Tube Boilers | Water Tube Boiler |

| Industrial Boiler | Gas Steam Boiler |

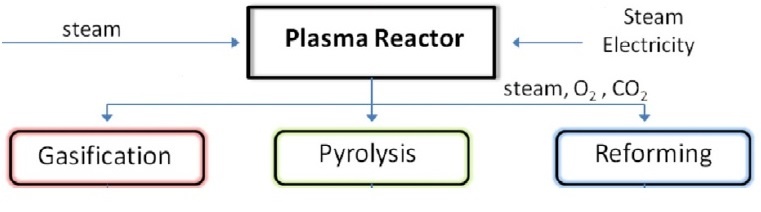

Gasification: Gasification is the conversion of waste materials in the presence of limited amounts of oxygen – a thermochemical process. Steam, or the oxygen in the air, is reacted at high temperatures with the available carbon in the waste material to produce gases such as carbon monoxide, hydrogen, and methane. Gasification processes produce “syngas” (hydrogen and carbon monoxide), which generate electrical power. Thermal gasification of the waste materials allows the production of gaseous fuel that can be easily collected and transported. Gasification typically takes place at temperatures from 750-1100°C.

Pyrolysis: This is a thermal process similar to the gasification above, which involves the thermal degradation of organic waste without free oxygen to produce combustible gases. Pyrolysis uses heat to break down organic materials without oxygen, e.g., with steam heating to 1250C. Materials suitable for pyrolysis processing include coal, animal and human waste, food scraps, paper, cardboard, plastics, and rubber. The pyrolytic process produces oil which can be used as a synthetic bio-diesel fuel or refined to make other valuable products. Sometimes the byproduct of pyrolysis is a fine-grained bio-charcoal called “biochar,” which retains most of the carbon and nutrients contained in biomass and can be used as a soil enhancement to increase soil productivity. During Pyrolisis, volatile gases are released from dry biomass at temperatures up to about 700C. These gases are non-condensable vapors such as CH4, CO, CO2, and H2, and condensable-vapor of tar at the ambient temperature. Cellulose can break down into Char, H2O, CO2, and methane.

Combustion: Use the Airtorch+Steam combination for a clean, most common, and well-proven thermal process using various waste fuels. Municipal and household waste is directly combusted in large waste-to-energy incinerators as a fuel with minimal processing, known as mass burning. Combustion can be with a solid, liquid, or gas reactant with oxidation. The Boudouard reaction (solid combustion) is stable above 700C to eliminate CO2 because CO2(g) + C = 2CO(g). Above 700C, one can use CO(g) as a reductant for oxides, as is done for iron oxide reduction. Link to MHI Fluidized Bed Designs.

Digestion: Landfills are the primary disposal method of municipal solid waste; if left undisturbed, landfill waste produces significant amounts of gaseous byproducts, mainly carbon dioxide and combustible methane (CH4). This landfill gas or biogas is produced by the (oxygen-free) anaerobic digestion of organic matter. Treatment by steam is often recommended for the elimination of certain harmful bacteria. Anaerobic digestion to produce biogas can naturally have a landfill gas or be inside a controlled environment like a biogas digester. A digester is a warmed, sealed, airless container where bacteria ferment an organic material such as liquid and semi-solid slurries, animal wastes, and manures in oxygen-free conditions for biogas. An advantage of anaerobic digestion for converting waste to energy fuel is that it employs semi-solid or wet waste. This is usually a small-scale operation. The biogas produced can be burned in a conventional gas boiler to produce heat or as fuel in a gas engine to generate electricity or fuel some farm vehicles.

Fermentation: Fermentation uses various microorganisms and yeasts to produce liquid ethanol, a type of alcohol, from biomass and bio-waste materials. The conversion of waste to energy by fermentation requires a series of chemical reactions to produce ethanol biofuel. Here steam can be directly introduced for rapid kinetics. Multiple reactions occur. The first reaction is called hydrolysis, which converts organic materials into sugars. The sugars can then be fermented (similar to making alcohol) to make dilute ethanol, which is then further distilled to produce biofuel ethanol.

Waste to Fuel reactions can also be considered, and there is a push to make liquid fuels using many responses. The focus of these reactions has changed because of the CO2 and CH4 greenhouse problems. Ask MHI about simulated photosynthesis and flavor reactions. Click for sample nano-catalyst coupons.

Waste to $-Fuels

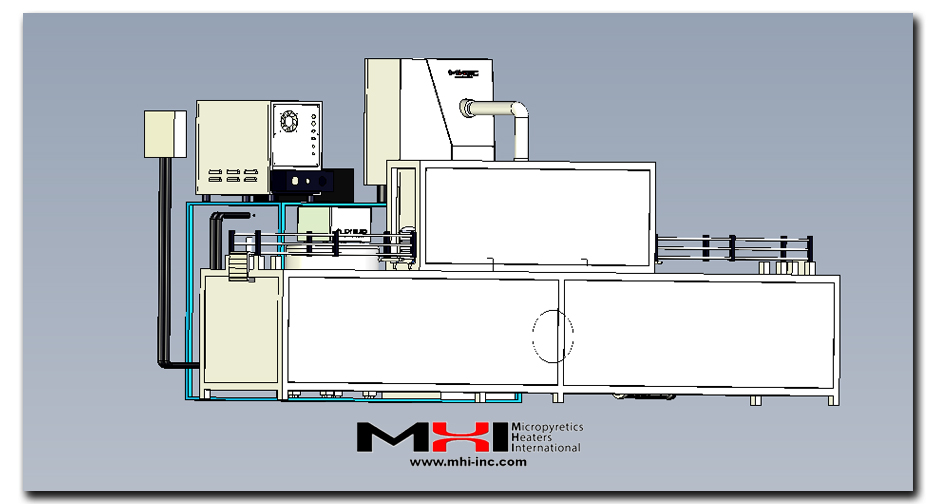

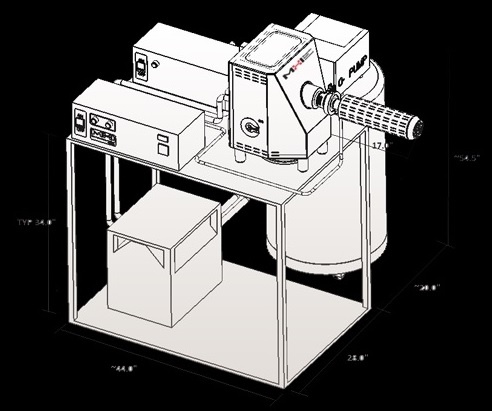

Layout OAB 4-900

The instant high-quality high amount of steam

Steam-jet cleaning of glassware such as glass-vials with 550°C superheated high quality steam. Results from https://bayzi.com/ohio-state-presentation are only guidelines for biofilm elimination- please verify directly.

Please link to video if your browser does not support the video.

|   |

Traditional boilers yield saturated steam (Tsat and Psat are linked). Note that Steam generators do not have to operate at high pressure for high temperatures. They work at 1 Bar safety. Thus one can get high temperatures without unwieldy pressures – with a steam generator. For example with a boiler, one needs a high 10 Bar and even then the saturation temperature is only 180°C -even at 100 Bars, the saturation temperature is only 311°C.

Steam generators operate routinely at 300°C, i.e. well above the inversion temperature. If the steam is for heating purposes, please compare the enthalpy and you will be surprised. If the steam is for work purposes please use the work potential row below, the work potential increases with both temperature and pressure. Work potential is measured from 25°C base temperature.

The cost of boilers increases for very high-pressure ratings. Traditionally the steam generators offer 95%+ efficiency – boilers could be much lesser and also lose efficiency with pressure ratings. However, even at 100 Bars, the saturation temperature is only 311°C. Again a fairly easy and routine temperature from the OAB type steam generator.

1 Bar =100000 Pa = 14.5 psi, 10 Bar =1000000 Pa =145 psi, 100 Bar = 107 Pa = 1450.3 psi

How much money is saved from energy savings with intelligent steam power technology

| Lower power consumption by : | 100 kW | 1000 kW | 1 GW approximate |

| Approximate savings per year of : | $87600 | $876000 | $876 x10^9 |

Assumptions include one kWhr cost of 10 US cents. Continuous use for the year.

Productivity vs. Temperature PDF

Using fossil energy like fuel oil, gasoline, or natural gas for heating creates considerable CO2.

| Kilograms of CO2 per million KJ (kilojoules) (Source) | |

| Natural Gas (the main component is methane), 50.4 | |

| Jet Fuel, 68.8 | |

| Bituminous (coal), 88.8 | |

| Diesel and Home Heating Fuel (Distillate Fuel Oil), 59.9 | |

| Gasoline and Ethanol Blends, 64.1 | |

- On average, one ton of CO2 requires fossil fuel to burn and produce heat of approximately 20 million KJ.

- One industrial process heater (15MW) could use 245 Billion BTU for a year. That is a lot of CO2 production – about 12,000 tons or more of CO2 from one large industrial dryer yearly!

- The social (environmental) cost of producing/emitting CO2 gas varies from US $51 per ton (Federal Estimate) to about $185 per ton (other estimates) (Source)

Key Parameters (typical) for Various Steam ApplicationsHow much money is saved from energy savings with innovative steam power technology | |||||||||||||||||

| Use the OAB® Steam for Softening Heavy Oil in Wells and Tanks. The transition towards smart capital expenditure (CAPEX) and innovative operational expenditure (OPEX) is imminent in the oil and gas industry, especially with volatile barrel prices. Reduce footprint. Easy to carry. Reduced use of electricity and water. Use for Oil Mud. Most Compact. OAB® Oil Softening Test. For Oil Wells. Pilot Plant Steam Generator for Possible Pharmaceutical Applications. It is safer because of no pressure leaks, high-temperature kinetics, and energy efficiency. Hot CO2, Hot sCO2, and Hot steam (H2O) are highly productive solutions… only from MHI. | Simple SaniZAP Clean dirt and grime in difficult-to-reach places. First, soften and clean with handheld superheated steam, then power-blow with hot air. Need more steam – the OAB models are ideal. Steam-soften with the proper superheated MightySteam. Then VTA hot air blow with the powerful VTA-1GC hot air power-blower unit. Simple. No water mess and use of the highest temperature steam. Use for restorative cleaning and de-greasing. What are the germiest spots in an airplane? Super Heated Steam in the Fight against Hospital Acquired Infections Contact us to see what data we have on Bed-bag removal with MightySteam and superheated steam. Pilot Plant Steam Generator for possible steam reforming, with carbon, bio-products, bio-charcoal gasifier, methane, and nitrogen for ammonia applications. The steam generators from MHI, namely the OAB and HGA devices, are efficient, controllable, and clean. For example, the reaction 2N2(g) + 2CH4(g) + 2H2O(g) + O2(g) = 4NH3(g) + carbon oxide by-products is a negative free energy feasible reaction at 400C. Or use biodiesel or carbon to produce hydrogen or other clean fuels. | ||||||||||||||||

| Electric Steam Generator. Foam cutting at high speed, low power, no mess with thermal steam cutter. Use the best steam that evaporates on cutting. Ultra-High Purity Steam. Also called UHP or UHT steam. Textile, continuous heat setting, and laundry steam chamber use. Superheated Steam Generator for use in steam oxidation studies. Use HGA-S or HGA-M. Continuous steam. Unlimited capacity. | Can you find a better paint remover? Save big on easy paint removal techniques with MHI steam from enamels to hard paints (view PowerPoint – inquire or rapid buy). Foam cutting. Thick foam cutting speeds ~1″/s. Improved energy, less water use, improved speed, and quality. Save 90% of energy for cleaning (for example, bird droppings)—consumer packaging labels. | ||||||||||||||||

| Energy is Saved for Laundry or Garment pressing. Car seat Pressing. Laundry Use. The energy requirement is approximately 0.15 – 0.30 kWh / kg of linen (source https://vdocument.in/module-3-session-2-respiratory-hygiene-module-3-session-2-respiratory-hygiene.htmlhttp://www.rabc-wfk.com/module3/Module3_EN.pdf). This is a good number for dry-cleaning, but for complete steam drying, it may be best to use a number like ~1kWh per /kg. If you are using and paying operationally for a 300kW boiler (1,024,327 BTU/hr) (or 30BP), are you dry-cleaning 900 kilograms (close to a ton of linen) of laundry in an hour? If this is not so, please consider OAB instead to save energy. The cost of energy is similar, whether gas or electric. Click here for savings from energy efficiency: garment de-wrinkle, heat setting, and textile conditioning in a rapid, energy-efficient manner. Energy saver for heat set of textiles (dye drying). Choose the OAB® Models. I am drying silicates, sand, porcelain, and investment molds during casting. | Drying with steam- ceramics to textiles. Choose steam higher than 250C. Noncondensing. UNLIKE MOST PRESSURE VESSEL-TYPE BOILERS; note OAB steam generators may be turned off and on quickly. Continuous steam without pressure drop is again best for quality control. Most often, neither pressure nor vacuum is required in applications. Pressure is often just a way for traditional boilers to achieve high temperatures- not needed for the specific application. See also Steam Energy Calculator and Steam Kinetics. Seats are pressing in rapid demand operations like automobile seat manufacture. At 10 cents per kWh, a 300 kW boiler operational cost could be as high as $30 an hour. A 10 kW OAB machine reduces this payment to ~ $1 per hour. Whether a 12 kW OAB may substitute for a 300 kW boiler depends on the application. The OAB® can meet most applications where a high-velocity jet is required. Many electric companies offer grants to make capital changes with energy-efficient new machinery. Please see the video in the Videos and Media Gallery section. In many applications, a de-superheater is required. This is a complex mixing of steam and water and is nozzle-dependent. The OAB, HGA-S, and HGA-M provide modern solutions for mixing at reliably low-cost conditions improving, improving. | ||||||||||||||||

| Improving starter oxidation for copper tubes. Steam Testing of Pipes. Steam Copper-tubes for water delivery to start a protective oxide (Malakite) barrier in them. Reduces copper contamination and other contaminants from pipes that do not have this starter oxide. Do internal pipes. Please contact MHI for a known technical prereferral referral to the proper EPA laboratories for your clarification. Users may need to call a government agency for proof of results. Please contact MHI for details. Steam cycle testing in lined pipe and vessels per ASTM F1545 | High-pressure steam boilers can be avoided. Laundry boilers, tunnels, and other energy improvement uses are possible in the garment and laundry industry. Several levels of efficient cleaning and de-wrinkling Higher temperatures de-wrinkle leather more easily. For example, clean fifty-pound loads with an OAB® and canopy. The canopy does not need to be a heat-dissipating rigid surface! | ||||||||||||||||

| Choose your steam bluing/blackening for attractive surfacing. Use the steam generator for steam oxidation studies. | Use Process Steam for oil (regular and heavy oil) and natural gas to reduce viscosity. | ||||||||||||||||

| Commercial Steam Boiler and OAB. Cheese Making. Heat processing to make cheese varied in the types of technologies used in practice. The time and temperature program for heating is determined by the heating method and the cheese type. Some cheeses require heating to temperatures above 40°C-56°C (133°F). Usually, at 37 – 38°C, the activity of the mesophilic lactic acid bacteria is retarded. Time is taken to check the acidity; above 44°C or more, the mesophilic bacteria are deactivated and killed if held at 52°C between 10 and 20 minutes. Heating beyond 44°C is typically called scalding. Some types of cheese, such as Emmenthal, Gruyère, Parmesan, and Grana, are scalded at temperatures as high as 56°C (133°F). Some of the most heat-resistant lactic-acid-producing bacteria survive this treatment, e.g., Propionibacterium freudenreichii ssp. shermanii“. Credit to http://www.food-info.net/uk/dairy/cheese-production is acknowledged for the above information. | Pure Steam Generator. Milk and Cottage Cheese. Augmentation of process. Significant energy reduction from unwieldy and high Btu/hr (kW) boilers is currently being used. A frequently asked question is: I understand that milk products have increased considerable resistance to deterioration when using UHT steam. However, will this denature the protein in any way that is bad for me? The answer can be found on website sites like http://www.bodybuilding.com/fun/muscle-mystery-does-denatured-protein-still-make-you-grow.html. Bakery Operation with on-demand(on-off) steam. Food processing humidification. Benefits may also follow from SW-OAB® Steam, saving considerable energy for shrink-labeling activities. — OAB® and MightySteam®’s patented heating system Dry Steam OAB(TM) and HGA(TM): Steam cleaning is a viable alternative to solvent cleaning in various applications, such as metal surfaces, electronic components, gilded art objects, anilox-rollers, decontamination of microbially-contaminated surfaces, disinfection, and sterilization, food decontamination, weed extermination, and radioactive decontamination. | ||||||||||||||||

| Continuous Superheated Process Steam for Odor Removal and Other Uses. Carbon Activation. Superheated steam can activate physical/chemical carbon, enhancing carbon nanoporous and porous structures ( about 10-(50-80) nm). The resultant carbon is called activated. It is highly porous and activated. This nanoporous/mesoporous microporous structure is expected to enhance the removal of toxic hydro-carbons and other dangers from wastewater/waterworks and fas. The continuous stream temperature required is more significant than ~800°C and dry. Please consult MHI for known techniques for start-up carbon-containing canopies or drums. A critical requirement for this is the availability of instantaneous steam within minutes because moisture, if present, tends to clog pores. The OAB-4 system or the OAB-12 system makes immediate steam. Please see the video on Videos and Media Gallery. | Electric Superheated Steam. What is the difference between Disinfection and Sterilization? See the box below. Steam temperatures greater up to 1300C. | ||||||||||||||||

Nightmare bacteria, shrugging off antibiotics – on rising in the USSteam Sanitation: Studies have shown that even 1 second of residency time of 248°F (120°C) steam is roughly 97% effective against common strains of bacteria1. This result most likely follows the common law of chemical kinetics, where speed increases exponentially with temperature. In controlled experiments, higher-temperature steam requires lower residency times to achieve effectiveness. | What is the difference between Disinfection, Sanitizing, and Sterilization? Sterilization vs. Disinfection vs. Sanitation There are three relatively commonly accepted levels of “clean” in many industries. Sterilization refers to the statistical destruction and removal of all living organisms. Disinfection generally refers to inanimate objects and all vegetative cells, but not spores. Sanitation refers to reducing microorganisms to safe levels from a public health viewpoint. According to the Association of Official Analytical Chemists, the official definition of sanitation for food product contact surfaces is a 99.999% (5-log) reduction of contaminants in 30 seconds. For non-product contact surfaces, a 99.9% (3-log) reduction in contamination is necessary. What is antimicrobial cleaning? Sterilization requires 6 to 12 logs or more cleaning potency, primarily done in steam sterilizers approved for this purpose. The antimicrobial market has been mostly comprised of chlorine (bleach), ozone, quaternary ammonium compounds (quats), per-acetic acid (PAA), formaldehyde, glutaraldehyde (aldehydes), and hydrogen peroxide. All of these technologies have limitations in addressing sanitization and disinfection needs. Steam is powerful. Se Patents Other published patents have shown superheated steam can clean up to sterilization levels. Patent numbers 8,940,245, 8,945,468, 8,652,403, 8,435,459, and many others are available. See also http://www.diffen.com/difference/Disinfect_vs_Sterilize | ||||||||||||||||

| Steam Boiler for Steam Kettles, Processing Mash with Steam, Saving Energy and Materials. Save considerable energy and time. Generally, from a cold start, cut up to 1/3 the time. Will preservatives be reduced by steaming – most likely not. | Commercial Steam Generator for packaging View efficient steam tunnels for packaging, shrink wrap, antimicrobial, and textile. | ||||||||||||||||

| Industrial Steam Generator and Tunnel for cotton fiber moisture doubling. Moisture in cotton yarn fiber can make the fiber more abrasion-resistant and fatigue-resistant. It is used for heat-set and saves considerable energy—there is no need to use a vacuum or pressure chamber. Review amazing ROI. SaniZap® technology is employed in the MightySteam™ line of steam cleaning products and by the MightySteam™ service, which represents a service that provides for the cleaning of the interior and exterior surfaces utilizing full superheated steam for residential, commercial, and industrial purposes. | Tankless Instant Steam Generator

| ||||||||||||||||

| Endotoxin Free Steam | Industrial Steam Boiler | ||||||||||||||||

| Why is Steaming Better than Boiling for Food? In some cases, steaming is preferable to boiling because there is no loss of mineral salts or food substances. The flavor is less likely to be lost than when food is boiled. Some delicate fish are best cooked by steaming as they do not break up as they might in boiling water. Vegetables prepared in this way prove very palatable. Very often, variety is added to the diet by steaming bread, cake, and pudding mixtures, and then, provided a crisp outside is desired, placing them in a hot oven to dry out the moist surface. Did you know the cost of steaming with superheated steam is less than 0.1 cents per dumpling? | Low-Pressure Steam Boilers | ||||||||||||||||

| Electric superheated steam generator for heat treating metal parts for oxidation. Steam heat treat for valve guides and valve seats, gears, oil pump rotors, engine bearing caps, rocker arms, transmission components, shock absorber components, bushing, and many metals, including copper and bronze bearings. Refrigerator parts include pistons, connecting rods, valve plates, general machine parts, and home appliance parts like a cam. | High-Pressure Steam Boilers | ||||||||||||||||

| High-Temperature Steam | Low-Pressure Steam | ||||||||||||||||

| Low-Pressure Steam Boiler | Steam Generator Boiler/Electric Steam Boiler | ||||||||||||||||

| Steam Roasting. Rare-Earth processing by steam. Activated carbon by steam in both Stage 1 and Stage 2 (Steam of 700C and 1100C). Rare earth metals are a group of 17 elements – lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, scandium, yttrium – that appear in low concentrations in the ground. | Use OAB Steam for Chemical Reactions Steam Reactions with Hot Clean Steam e.g., heating of a liquid ethanol-water azeotrope/azeotrope Azeotropic distillation | ||||||||||||||||

| Electric Steam Super-heater steam steam | Steam Boilers | ||||||||||||||||

| Steam Reforming Hydrogen | Wine barrel conditioning and reconditioning. See also hybrid. | ||||||||||||||||

| Heavy Oil recovery with low energy and water input. | Use in Oil storage and Oil tanker applications. | ||||||||||||||||

| Wood Conditioning for utility, packaging, and hobby use. | Safe kettle-heating for Breweries, Flavors, and other such use Industries. | ||||||||||||||||

| Energy-efficient kettle heating for Breweries, Flavors, and other such uses. | Superheated Steam Drying | ||||||||||||||||

| Instant Steam Generator | Superheated Steam Boiler | ||||||||||||||||

Touch-up steam – 1 kg/hr of steam up to 400°C. Use for steam spray purposes only.

![]()

How much money is saved from energy savings with smart steam power technology

Assumptions include one kWhr cost of 10 US cents. Continuous use for the year.

Why use an autoclave when modern steam can be obtained instantly and without pressure at the correct high temperature?

Why use an autoclave when modern steam can be obtained instantly and without pressure at the correct high temperature?