Industrial Applications and Use of Cascade e-ion Machine Stations

MHI’s unique Cascade e-Ion Plasma™ features novel technology that allows it to replace existing processes while simultaneously improving efficiency and productivity. Immerse in CleanElectricFlame® for non line-of-sight processing or BendHeat™ requirements. The unique plume allows direct rapid processing of surfaces and maintain cleanliness even for air processing.

Cascade e-Ion Plasma™ and Machine Use(Patented products and treatments, available only from MHI) | |

| Hard Coat or refurbish tool bits, drill bits, machine tools. Save energy, double drilling speed, more life and improve ease of tapping. | Nitride biomedical parts, hardface, oxynitride, add silicides. Finish processing in seconds. Use gas of choice including only air for nitriding |

| Brazing Aluminum to Steel to Magnesium, Aluminum to Magnesium, Plus other combinations of brazing ferrous to nonferrous metals. 3DBrazing® and 4DSintering® are a registered trademarks of MHI. | Rapid Deburring and Smoothing from Metals to Plastics. Smooth Finishing. Ionic Deburring and e-Ion Peening if Biomedical Parts. Titanium Nitriding. Carbon Nitriding. NitroCarburizing. Please call MHI. |

| Nickel or Cobalt Alloy Brazing and Hardfacing Nickel or Cobalt Alloys. Request FREE White Paper Rapid tool-bit manufacture of WC-Co with embedded ceramic particles | High-intensity die heating similar exceeding performance by Induction, SW-IR, or Laser. Please contact with a request for free report for heating rate and non-line of sight uniform heating. |

| Plastic Surface Functional Manipulation (please download the ideation brochure).Plasma Ideation Brochure. | Surface treatment without grounding object. Possibilities from water to paper and pulp industry. Possibly use for activating carbon or other surfaces by the ion charge and temperature in the CleanEletricFlame. |

| Active Metal Brazing & Ceramic Brazing | Surface sintering and sealing |

| Plastic welding or layering or quick layer adhesive bond formation. Biomedical coatings with De-e-Ion. Simple, safe, easy. Easy ability to create bio-inspired surfaces Create Hydrophilic or Hydrophobic surfaces.

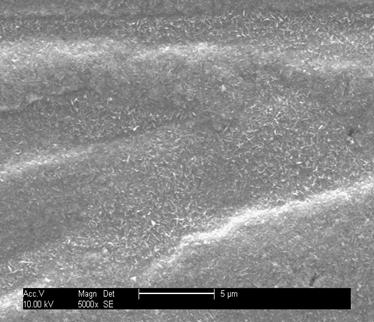

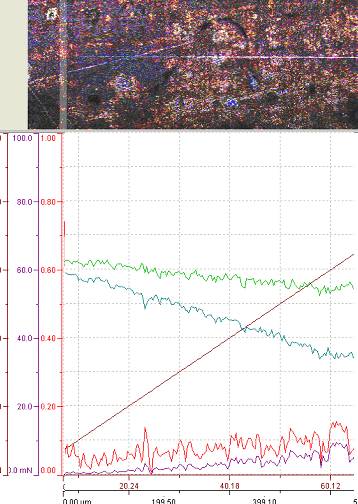

| Smoothing and conditioning. Connect to air/gas source and electric. Small foot-print. Use for metallic deburring especially for biomedical parts for example made from Titanium. Cleaning extruded plastics. Avoid toxic chemicals. Unique power adjustments are possible. High-value parts such as transportation (Land-based, water-based, or air and space-based). Ecological solutions, for health reliability monitoring of parts for inspection” Plasma Ideation Brochure. Scratch test yields COF ~0.1 on coated stainless 304. |

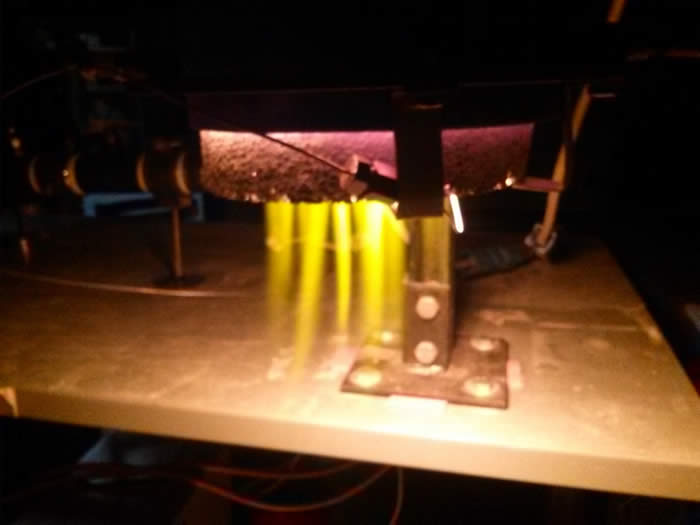

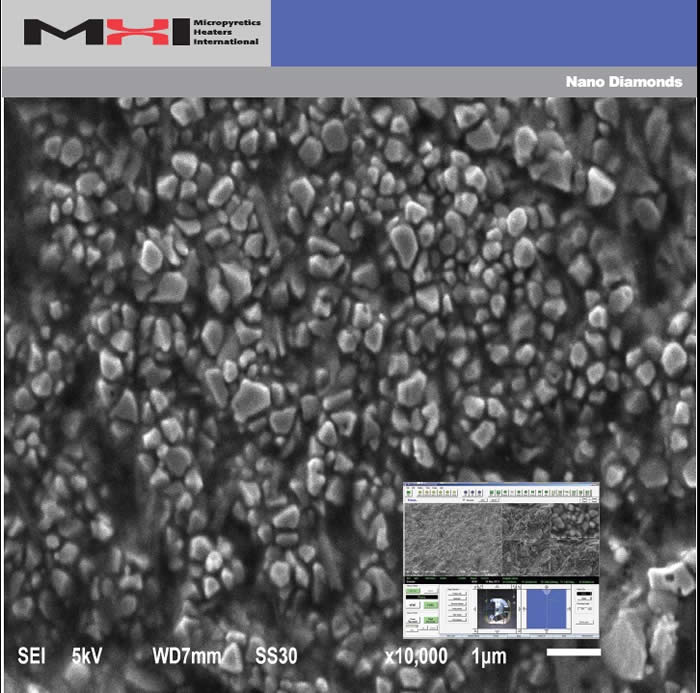

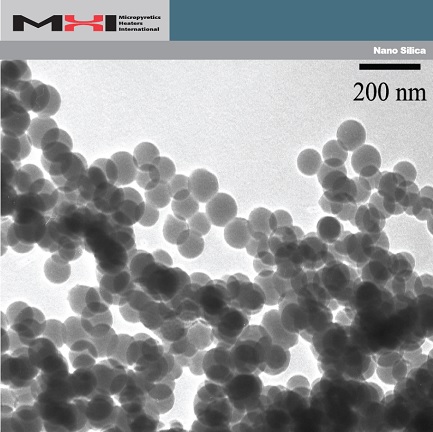

Dross Reduction in Metallic Liquid Melting and Holding Furnaces. The Cascade e-Ion is used to melt or cover melts without the need for the chemicals that are used currently to prevent metal loss from slag formation. Two pictures are shown below – a conventional heater/burner was replaced with the Cascade e-Ion melt from air plasma. Note the significant reduction in slag and better quality of the overall melt (now shiny). (Download Plasma Applications for Aluminum Supplement). The use of the Cascade e-Ion leads to substantial savings in metal recovery accompanied by reductions in the use and disposal of harsh chemicals. Use for aluminum, silver liquation, and other dross as the special reducing ionic beam comes into play. Large savings and very high ROI for air cascade e-ion cover for aluminum, zinc bismuth, silver, gold, lead, and other metals for refining, beneficiating or separation as applicable. Dross reduction without chemicals | Use De-e-Ion™ for cleaning and simultaneous application of nano surfaces, dyes and other defect markers. Diamond surface coating and Nano-silica powder

Nitrides, Yittria Zirconia, Boron Carbide, Silicon Carbide, Molybdenum diSilicide. Titanium Nitride (from the air through the cascade e-ion) Glass and Nano Surface Depositions. |

| Thin Film Deposition. Molybdenum DiSilicide by ionic deposition and deposition of other nitrides and carbides. Quick ion-assisted deposition. Thermal barrier coatings include functionally graded coatings with both ceramics and metals. Easy use with precursors. | Improve surface adhesion and wettability. Deposit carbides, nitrides, borides, phosphides sulfides, and more in a graded fashion for various functional uses. |

| 3DBrazing® (Multi-dimensional Brazing) | 4DSintering® (Multi-dimensional Sintering at rapid cascade-ionic speeds) |

Industry-Specific UseIon/Plasma Nitriding, Rapid Diffusion Brazing, Tool-bit repair, Glass bending, Diffusion, brazing, Output Shaft Hardening, Horizontal Drive Bar Hardening, Shock Absorber Stem Hardening, Axle Shaft Hardening, Constant Velocity Joint Hardening, Hardening of power take-off, Shaft Hardening, Bolt Head Hardening, Heating of titanium and/or stainless steel wires, Hard Metal Tool Brazing, Resistance Brazing, Gauge Brazing, On-line tempering of mechanical parts, Shrink Fitting, Hardening and tempering of chains, Agricultural Tool Sectional Hardening, Drive Shaft Hardening, Stub Shaft Hardening, Power Transmission Shaft Hardening, High Wear Application Hardening, Automotive Axle Shaft Hardening, Internal & External Tube Brazing, Honeycomb brazing, Oil & Gas Wear Resistance Surface Treating, Rapid Tool Bit Manufacturing (WC-Cobalt), Manufacturing Shiny Parts without Reducing Gas. Copper Brazing, Low to mid-carbon steel heat-treatment (4140 grade), Bio Implants of Plastics, Cobalt alloys or Titanium alloys for various types of surface enhancements from antimicrobial to best fusion with base metal, Decontamination, Textile Processing, Non-line of Sight Heat Processing, Fluorocarbon deposition, Fluoropolymer deposition, Silicon Deposition, Rapid Epoxy Deposition and Curing, Glass Substrate Deposition, Electronic Polymer Applications, MEMS, Carbon Nanotube or Fiber Production, Compare to electron or laser beam Melting RTP processing, annealing of semiconductors like Si, SiC, Diamond and GaN. Ionic synthesis methods or ion-assisted methods for improving luminescent properties of nitrides, silicates, and phosphors. Electronic Materials Fabrication. Most Nitrides and Oxynitrides display very low wear rates. The rate for chalk in comparison, one that has low wear resistance, is in the order of 10**–2mm3/Nm, and that of diamonds is between 10**–9 and 10**–10 mm3/Nm. The Cascade e-Ion applications include those in extractive metallurgy, mining, and ore separation, with uses that enable the better collection, beneficiation, refinement of precious metals, and metal/metal oxide reduction and or separation. The energy savings techniques that allow possibilities of change from 200kW machines to 15 kW cascade e-ion machines, embrace particle sintering to controlled oxidative separation. The potential uses for the cascade e-Ion are for augmenting chemical-free misch-metal and precious metal production. Please contact MHI for more details. The Cascade e-ion offers a good return on investment (ROI) for several applications such as melt covers, dielectric rapid processing, nitriding, and a host of other applications. | |