Dross Reduction by Plasma Enhancement.

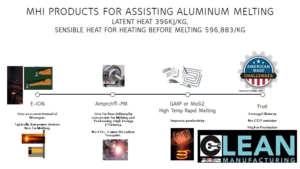

The following is a detailed description of how the wide-area plasma product can improve aluminum processing efficiencies.

Fit to any existing melting or holding furnaces. The addition of the environmentally acceptable quiet plasma device to any existing furnace is expected to enhance efficiency and significantly decrease dross loss. Comparison of melt cleanliness

SAVE: There may be no need for any nitrogen cover when appropriately used.

Decarbonization and radical energy efficiency improvements with low dross. (Project Costs)

ADVANTAGES (FAQ’s)

- Key to melting aluminum cleanly.

- Key to high productivity in the aluminum industry.

- Dross values less than 0.5%.

- Extremely small footprints.

- Quiet (not like conventional plasma, which is very noisy). Improved worker acceptance is entirely expected.

- Close to 100% power transfer efficiency of plasma device- compared with low-efficiency conventional plasmas.

- Reduce or eliminate nitrogen, argon, or fluxes.

- Also, seFAQ’s FAQ’s (bascustomers’omers’ questions)

- The Cascade e-ion is not for use as a stand-alone melting furnace. It is an add-on to a new or existing aluminum furnace. The model you require is our DRO-Cascade-eion-10 or DRO-Cascade-e-ion-3.5. This is an electrically powered 10kW or 3.5 kW output directed at the surface of the liquid metal. Please consider it an efficient gas top that provides 10kW or 3KW of heat. t is continuous. Given below is a comparison ROI. Please verify with MHI should you have questions.

- Dross savings = Energy Savings.

- Approximate ROI. The savings are from dross reduction, so the ROI is tied to the total metal produced/processed. For example, if the price of 1 ton of aluminum is $1000, then a 2% savings in dross is $20 in savings. If this furnace makes 100 tons in one year, the savings is $2000. Of course, the secondary aluminum market likely sells at about $2000 per ton of processed metal. The calculations below are with $1000 per ton.

Most small-scale aluminum plants process about 10 tons a day per furnace. Assume one year has 200 working days; this equals 2000 tons a year per furnace. A $20-a-ton savings per year is $40,000. or small furnaces in this category, we would recommend the DRO-Cascade-E-ion.

- It has been reported that a gas-fired furnace dross can be as high as 10%. This means the savings correspondingly would be about $200,000 to $1,000,000 per year. If the price is $2000/ton, the savings range from $80,000 to $2,000,000 per year, depending on the tonnage, model number, and dross scenario ROI’s are attractive. Or DRO models, MHI has a never-down –policy, which is very cost-effective in ownership. This cost is typically within 10-15% of the purchase price and far below the maintenance costs for thermal equipment. The standard warranty is 1 Year.

If employed well, an energy efficiency of 0.2kWhr/lb with no emissions can be expected, in addition to low dross when the heat is also used for melting. However, low dross is the primary benefit.

Typical Energy, Dross, and Melting Rate Values For a Plasma Aluminum Melting Furnace Powered with a Plasma Device ….. (go to detailed comparison table).

Additional information:

- Environmental and economic benefits: Return on Investment (ROI)-please contact.

- No need for nitrogen cover

- Small footprint and no noise

- Summary results of Plasma Aluminum Melting furnace

- Ingot, sprue, and scrap melting

- How do the energy density values of PAM furnaces compare with conventional furnaces?

- How does the quality of melt compare with conventional furnaces?

- PAM furnace vs. electric melting

- Measured energy saving

- Environmental (waste) savings

- Economic analysis of various types of furnaces

- Summary of the qualities of most conventional and the new Plasma Aluminum Melt furnaces

The units may be added to an existing holding furnace or launder systems to improve the dross loss and achieve higher production rates.

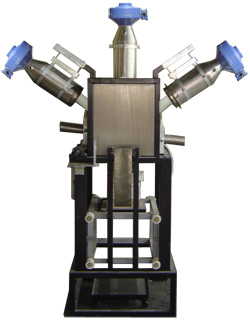

The picture shows three 6kW plasma devices attached to a furnace. Normally, one unit can produce more than 10**20 ions every minute, depending on the power.

For dross reduction, choose one unit to start and add more if needed. It is easy to apply to a flat surface.

The units may be added to an existing holding furnace or launder system to improve dross loss and achieve higher production rates.

The picture above shows three 6kW plasma devices connected to a furnace. One unit can produce more than 10**20 ions every minute depending on the power.

For dross reduction, choose one unit to start and add more if needed.

![]()