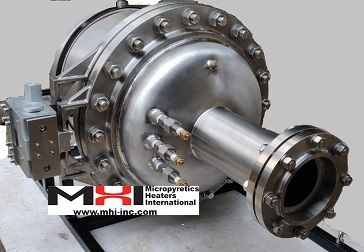

Electric Airtorch®

Electric Control Panels from MHI Inc.

Process Gas Heater

Electric process air and gas heating solutions. Compact units with a range of power and temperatures to meet the industrial sector’s strict targets for high energy efficiency and productivity.

Contact Us

**Introducing the Electric Airtorch®**

MHI’s innovative air and gas heating solutions are designed to help the industrial sector meet stringent energy efficiency and zero-carbon emission targets. Contact us to discover how we can transform your industrial heating processes.

MHI manufactures an energy-efficient line of electric process heating products for use across a wide range of temperatures, from low to very high. MHI Airtorch® products are patented. |

Overview:

|

Models:

For help choosing the right Airtorch® for your application, click here for the Selection Guide.

Typical Features:

- Wide power range: Highly compact electric gas heaters available from low kW to 200+ MW, suitable for both pilot and large industrial systems.

- High-temperature capability: Achieves up to 1200°C outlet temperatures with variable inlet temps up to 400°C and higher; optional re-circulators further boost thermal efficiency.

- Decarbonization & efficiency: Fully electric design eliminates CO₂, CH₄, NOₓ emissions and delivers ~95% energy-conversion efficiency (vs. ~35-70% for combustion). Electric Airtorch® heater (E-heater™)

- Process performance: High-temperature operation and precise control improve productivity, heat transfer, and process uniformity in hot-gas applications.

- Low pressure drop & high turndown: Pressure drops as low as ~0.1 psi, enabling easy integration and energy savings across varied flow conditions.

- Highly reliable, low maintenance: Self-healing components, robust thermal designs, and minimal wear make it suitable for continuous, high-demand industrial duty.

- Consistent, precise heating: Engineered for stable, repeatable heat delivery—valuable in processes requiring tight temperature control.

- Broad gas compatibility: Heats air, hydrogen, inert gases, CO₂, syngas, and steam, with multiple flow/pressure configurations including high-pressure models.

- Application guidance: A full Airtorch® Selection Guide is available to help users match models to specific industrial requirements. These are excellent option for industrial use.

Please specify the following for a quick quotation.

- Outlet Temperature. For example, please specify 200°C, 1000°C, 1100°C, or 1200°C.

- Power. For example, 10 kW to 100 MegaWatts (A higher power is more expensive).

- Inlet Temperature. For example, 25°C, 300°C, or 550°C or more.

- Pressure drop not to exceed. For example, 0.1 psi for a 15 MW system.

- Gas Composition. For example, Air, Hydrogen, or Steam.

- High-pressure rating up to 50 bar.

MHI Airtorch units are made of stainless steel or alloy steel.

MHI Airtorch units are made of stainless steel or alloy steel.- MHI Control Electronics is considered one of the best in the world.

Ask MHI for the best warranty on heating systems. The heating element is warranted. MHI offers inline and cross line air heaters, compressed air heaters, process air heaters, jet heaters, hot temperature air heaters, comfort heating modules, and electric plenum heaters. MHI offers several models, from low KW to MW and duct heaters. MHI can provide Airtorch® units that span a wide range of flows for the same output temperature rating. Process gases include Air, Ar (Argon), O2 (Oxygen), CO2 (carbon dioxide), sCO2, N2 (Nitrogen), Syn-Gas, CH4 (Methane or Natural Gas), H2 (Hydrogen), CO (Carbon Monoxide), H2O (Steam), and many more. Each application requires unique materials and construction. Several specialties are patented designs that save energy using the MHI Rib-reinforced models for high input temperature.

Why choose the Patented MHI Airtorch®?

- KW to MW range for drying with 0.006 psi. Save on energy. Up to 60 Bar shells are standard when required.

- Use the best MHI-quality electric control panel standards. MHI panels are long-lasting and offer high quality.

- 1200C or more for test beds

- Extremely Compact, even for MW systems.

- High Energy Efficiency. (Click for the document with a typical comparison of process heat products).

- Choice of supply voltages. Please contact MHI.

- Rated and Certified Shell Pressures.

- Easy Serviceability. Friendly engineering support. Wide flexibility. Experienced staff.

- High-quality electronics with modern PLC and HMI controls. Easy interface with SCADA.

- One of the best warranties. Customer-centric, long-lasting, and crafted modern designs. Best Value.

- Application assistance from top-level scientists.

The Airtorch® is /an industrial air heater and process heater designed to heat air and other process gases to temperatures ranging from 20°C input to 800°C or 1200°C. It is one of the most compact and energy-efficient decarbonization heating methods available.

The Airtorch utilizes a convective system to heat ambient air and direct it towards a surface or chamber. It suits high-temperature industrial processes, including iron-making, cement production, aluminum and magnesium manufacturing, general high-efficiency heating, food and liquid heating, and glass furnace decarbonization.

Using the Airtorch can enhance the efficiency of various chemical and energy production processes. The price of an Airtorch increases with the required power, temperature, and pressure ratings.

Airtorch Video Introduction

Process Gas Heaters – Typical Comparisons

Users save energy, enjoy improved efficiencies (greater than 95%), completely prevent greenhouse gas emissions, and optimize their process using the touch screen or remote adjustment via ethernet by adjusting temperature and flow rate settings. Hot air production is almost instantaneous. The Airtorch is much lower in equipment and operational costs than comparable units. Very often, life is much higher. The external controls of temperature, humidity, and other parameters make the systems customizable for specific applications.

- Electric-powered operation for zero on-site carbon emissions and zero reliance on fossil fuels.

- Advanced technology for high energy efficiency, resulting in cost savings and a lower environmental impact.

- Customizable solutions to meet specific customer requirements and integrate seamlessly into existing systems.

- It has enhanced monitoring and control features for optimized performance and maintenance.

- Improved solutions for process enhancement with high efficiency and very attractive pressure drops.

The Airtorch is cost-effective because of its energy efficiency, low-pressure drops, and compactness. It is simple to use and install. It saves energy and improves process productivity—industrial heat decarbonization.

Sizes available from 1KW, 30 KW, 60KW, 104KW, 240KW, 5MW, 7MW, 9MW, 11MW to 100MW in a single compact unit.

- Compact

- Save substantially on electric costs

- Very high turndown ratios

- Ultra-low pressure drop

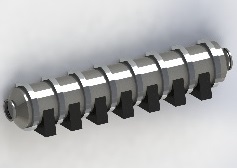

- Modular and Expandable (Ribbed Design)

- High temperature and high-efficiency

- No preheating required

- Compare energy efficiency. Efficiency improvements are achieved through patented innovative design, advanced patented heating materials, and sturdiness of construction. What is the competition’s maximum flow rate for a fixed power at any temperature? MHI can sometimes even be 100% better. Why trust anything else?

- Unlike combustion-powered devices, the MHI Electric Airtorch® does not produce greenhouse gases (like CO2, Methane, or NOx). Converting from combustion heaters to electric heat is expected to improve energy efficiency by 30%. MHI Airtorch® models offer patented ultra-low pressure drops with flows that enhance overall efficiencies and low product distortions.

Electricity-powered units prevent approximately ~200 to 700 kg/MWh of CO2 production at the Airtorch site compared to combustion units. The ultra-low pressure drop technology, high turndown ratios, and an outlet temperature of 20°C-1200°C enable additional energy savings. Low-pressure drops will be experienced in high-pressure enclosures with fully stamped ASME, UL, ATEX, and CE codes. Rapid temperature-rise units contribute to lower energy consumption.

Choice of shell pressure, unique construction, and ratings for even reactive and toxic gases like ammonia to mono-silane. New high-value duct modules for transforming combustion ovens to electrically powered air heating.

MHI is a known brand. MHI uses industry-tested electric control panels with a High-life warranty. Compare price, energy savings, product life, and warranty.

MHI customers are the first to be offered the most recent upgrades. The company provides a desirable NeverDown™ policy.

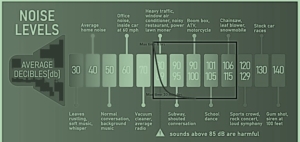

The Airtorch offers high outlet temperatures with low-pressure drops, high efficiency, compact, noise-free, energy-optimizing designs, quick-start, and high-temperature inlet capability. Because of their high-temperature capability, they provide a longer life at lower temperatures when compared to process gas heaters that cannot reach high temperatures. Several models are in stock, all quality-engineered and carefully manufactured. MHI has decades of electrical heating experience.

Stands, Mating Flanges, and Heat Shields.

Process Gas Heaters Comparison Table

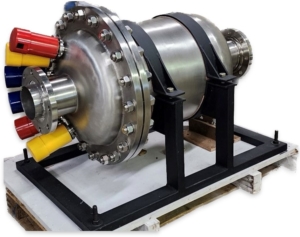

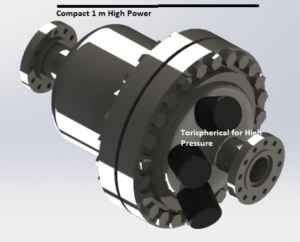

The Airtorch has high-quality torispherical terminations.

What is New

New Prices. Higher temperature inlets and outlets. More compact. Be surprised at the compact size of our MW heaters. Extremely low-pressure drop. Fibonacci heaters. Multiple third-party and approved ASME, UL, cUL, CE, and ATEX are available—compact Duct Heaters to 600C when required.

Our competition does not typically give the type of warranties we offer.

DH model 104KW, 240KW, 5MW, 7MW, 9MW, 11MW. The unit below is 100 KW ~12″ long with a 0.1 psi pressure drop.

MegaWatt Panels

Extremely compact and efficient and has a very low-pressure drop.

One-year warranty on heaters (Information)

Airtorch® Models are used in Heat treatment, Drying, Heating, Coating, Packaging, Furnace pre-heating, Engine Test Stands, Combustion Studies, Fuel and Petrochemical Sectors, Sea Water Rigs, Power Generation, Waste Heat Reclamation, and Chemical Industries.

Why are the MHI Airtorch models efficient? Prices scale with power, temperature, and pressure. Please discuss your best value with MHI.

The following categories of Airtorch models are available:

Large Flow. For 400-1200°C. Experience low-pressure drop savings. Duct Heaters. Process gas heaters with a blower or inline capability. High KW to High MW. – High Flow.

Large Flow. For 400-1200°C. Experience low-pressure drop savings. Duct Heaters. Process gas heaters with a blower or inline capability. High KW to High MW. – High Flow.  Contact MHI.

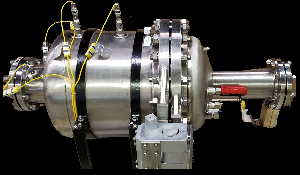

Contact MHI.GTA (High Pressure) —Up to 1200°C. Large Flow GTA—For high-pressure vessel Airtorch® use. Experience low-pressure drop savings with custom engineering. Please contact us directly for assistance. Contact MHI.

LTA and VTA – Up to 900°C. LTA is a process heater for air that requires a compressed air input. VTA is a process gas heater with a fan or blower and low-flow sensor capability. Contact MHI.

New* VTA with fan models for 1100°C. Contact MHI.

MTA925 and GTA925 up to 1000°C and MVTA or GVTA up to 1100°C. New Models for the MVTA-PDF-DNA Class. These flow or inline-sealed process gas heaters can take compressed air, steam, or gas input. Contact MHI.

DPF, VTA-MPDNA and GPD-MPDNA – Up to 1150°C-1250°C/~2200°F. PDF models can take fan or blower input and a compressed air/gas input. Contact MHI.

Inline-Airtorch® models for process heat are now offered with inputs of up to 20 °C to 550 °C into the Airtorch®. The output is up to 1200°C (~2150°F).

Please contact MHI for Airtorch® and Airtorch®-recuperation uses. Smart Recuperators.

Simple 5-step selection guide and flow as a function of temperature for various models.

Energy efficiency and uniformity of impinged surfaces.

Introduction to Airtorch® | Airtorch® Applications | Calculating Power vs. Flow Rate | Easy Design Criterion

Properties of Gases & Moist Air with Temperature. Why conserve energy?

Very High Temperature Available.

Operating Temperatures to 1200°C/~2150°F. DPF models can take fan or blower input and a compressed air/gas input.

Important volumetric conversion.[ 1 m³ = 35.315 ft³ ]

MHI special technologies allow for the following:

- Incredible Warranty.

- Inlet temperatures can be high on specific models of MVTA.

- Pressure drop: Very Low. MHI offers DirectFlow™ Airtorch.

- We use our combined thermal knowledge across diverse equipment offerings to optimize and provide low-friction Airtorch systems.

- Quick Selection Guide: If the flow rate is 2-40 scfm, please choose MTA, VTA, or LTA models or the MVTA925 models with flanges. If the flow exceeds 40 scfm, please select from the highly energy-efficient MVTA models.

- If the temperature required is above 1100°C, please choose the DPF models.

- When comparing Airtorch heating to other methods, please note that the MHI Airtorch systems do not produce appreciable sound.

Quick Units-Conversion : (800°C=1472°F) (925°C=1697°F) (1000°C=1832°F), (1100°C=2012°F) (5 Bar=0.5 Mpa)

Do you need higher temperatures? Please don’t hesitate to give us a call or contact us. The required kW depends on the exit gas temperature from the Airtorch™ models and the flow volume needed. Please use the Easy Design Criterion or this formula to calculate the approximate temperature vs. flow rate for a fixed power for an Airtorch™ model number. MHI also provides flow rate vs. temperature for TA and DPF models—request Graphs.

Allowed Air/Gas Inputs: Air/Gas from the compressor, blower, or fan may be attached (varies by model). Depending on the model, input such as Gas Cylinders, Compressors, Blowers, and fans may be used. Some Airtorch® models also accept high-temperature feed gas as an input. The Airtorch® models are highly efficient electric process heaters (inline, cross line, and independently standing models are offered). DPF models have very low-pressure drops associated with them.

Airtorch Operation: The flow rate and temperature are connected. The heater cannot go beyond its rated temperature or power. The thermocouple is integral to the heater. The principle of an air/gas heater is for flowing gas to heat within the residence time of the heater/configuration. The flow temperature curve is given on the Power Vs. Flow Calculator. This is shown for air and can easily be converted for different gasses and supercritical CO2 (sCO2) recuperators for a Brayton cycle demonstration.

Flow Rate is Important: If using a blower or fan, the airflow will be controlled by the fan’s or blower’s characteristics. Fans are employed when the system’s pressure drop is no greater than about 50 in. w.c. (50 in. w.c./inches of H20 is approximately 1.8psi.) This condition remains true even when the fan outputs large CFM values. Blowers are considered in circumstances where more significant pressure drops are present.

Every MHI Airtorch has a maximum power rating, temperature, and pressure rating (if rated to higher than one atmospheric pressure, i.e., the GTA models). Please follow the curve on the Easy Design Criterion while operating safely within the device ratings. The power should be fixed close to the rated capacity. Please maintain a low-flow cutoff sensor if used close to the highest-rated temperature. Please observe limits with care. MHI Airtorch models have multiple control and safety thermocouples and other safety devices.

Should I use a Compressor or Blower? Ans: The Airtorch units accept all types of inputs. Please contact MHI to check whether a particular blower or fan is suitable. The most crucial issue is not falling below the minimum SCFM rating or temperature for the maximum rated power. Fans are employed when the system’s pressure drop is no greater than approximately 10-50 in. w.c.

The MHI Airtorch uses are in Industrial Equipment, Combustion Simulation, Test Beds, sCO2 heating simulation-power cycles, CO2 heating even for chemicals even to make carbon nitrides, CO heating for clean reduction, clean method of waste to fuel including integration with modern high quality steam, Lab and Analytical Equipment Medical Equipment, Military and Defense, Urban decarbonization, rural decarbonization, decarbonize port cities, Rubber and Plastics, Pharmaceutical, Pharmaceutical Equipment, Transportation, Water and Waste Water, Clean=up of dirty sites for example in fisheries, Commercial, Adhesive Activation, Food Service Process Heat, Chemical Reactions, Laboratory, de-soldering Heat Staking, Melting, Energy Processes, Climate safe benefit, Energy, Soldering, Welding- Brazing, Weld preheat, Semiconductor, Medical, Preheating Gasses High speed heat shrink, Curing adhesives, Enegine Test Stands, Hot Air Processor, Powder drying and high temperature high velocity regime, Automotive, Packaging & Sterilization, Paper/Printing, Bio-Fuels, Digestion, Semiconductor processing, Soldering/Brazing, Textiles, Semiconductor, Energy Processes, Nuclear, Bio, Diesel, CyanoCarbons and Oxides, Process heater, gas heater, powder, gas pre-heater, air-pre-heater, supplemental heater and many other process heating applications.

MHI Airtorch® products are used as components in products for chemical processes, thermal energy storage systems, and various other applications. The Airtorch® product reduces climate risk, accelerates energy transitions, and increases health security. Use for flow simulation, whether combustion or high temperature, wafer processing, metal finishing, Solvent drying, or fertilizer drying such as ammonium sulfate, steam, air hybrid process heaters, Flow Air Heating, preheating, Hot Air Processor, Shrink Fitting, Synthetic Fabric Sewing. Pressure vessel, simulation, Baking, Laminating, Mold and Curing for many sectors, Drying and Vulcanization temperature control, Metal Working, Packaging, Plastic Welding, Sealing, Soldering and Brazing, Inline heaters, Compact heaters, Parts cleaning, Biomass extraction, Bio- reclamation, Photo-resist material, Semiconductor processing equipment, Supercritical fluid heating, Ore processing, drying and calcination, Solvent replacement, Testbeds, Life Sciences, Air, Steam, sCO2, Photovoltaic, Semiconductor processing, Curing and Drying, Electronics, Efficient Heat Shrinking, Thermoforming/Sealing […]

| Resources |

|

Typical Applic ations

ations

Applications of Airtorch Convective Heating Products:

Agriculture, Thermal Storage, High-density Heating, Aerospace, Drying, Calcining, Paper and Pulp, Hospitality, Automotive, Packing Industries, Oil and Gas, Footwear, Planting, Blow Molding, Degreasing, Power Generation, Shipping, Transportation, Coating, Household Appliance, Marine, Plastic & Rubber Processing Machinery, Chemical And Petro-Chemical, Die Platen Injection Heating, HVAC Air Heating and Sealing Bars, Furnace and Ovens, Hot Plates, Molds, Baking Incubators Food Warmers, Textile Pulp And Paper Water And Wastewater, Management Laboratory Equipment, Medical & Laboratory Apparatus, Heat Treatment, Green Steel, Aluminum, Food and Beverage, Building Materials, Cement, Clinkers, Hybrid Heating, Efficiency Enhancers and many more.