Front Loading Furnace – High Temperature – Large Roof Span

MHI can offer large roof-span furnaces with Nanofractal high-toughness, low distortion roof hangers.

MHI nanomaterial patents at work for our customers in heating elements and refractories

Thick low distortion stainless (double-walled shells) with easy access design

Check out other unique features that add to uniformity and productivity

M-14 GAXP

12″H x 12″W x 16″D

Front Loading Furnace Features

MHI’s extensive line of front-loading furnaces has the highest uniformity and energy efficiency ratings in their class.

Front-loading furnaces feature several features:

- Wide-span roofs

- MHI’s industry-proven MoSi2 or GAXP® heating elements for faster heating and greater energy savings.

- Top opening, counterbalanced door.

- Pneumatic door activated by foot pedal.

- Double-walled, heavy gauge stainless steel construction; the thickest in the industry.

- Sleek design minimizes furnace footprint.

- 3 layers of vacuum-formed alumina/Fiberfree(TM) refractory.

- Forced air cooling for minimum exterior temperature.

- 3 phase control with MHI’s TRIPAN control system featuring: state-of-the-art Eurotherm or Honeywell controllers.

- Controls are remotely locatable, allowing for centralized control of multiple furnaces.

- User determined hearth height for convenient loading. An optional stand is available.

- Our front-loading furnaces are designed for maximum productivity.

- Compatible with our low-cost Data Acquisition and Control Software.

- Contact Us for information on customizing production furnaces for process manufacturing and glass melting.

Useful Information

Front Loading Furnace Models

MHI front loading furnaces feature rugged stainless steel construction, electronic controls capabilities, and MHI’s highly acclaimed heating elements. Standard features also include a top opening, counterbalanced pedal activated door, 3 layers of refractory, and several ergonomic features to improve productivity. Front-loading furnaces feature maximum operating temperatures of 1800°C and continuous operating temperatures of up to 1760°C. See the tables below to determine which model is best suited for your application.

| Model Number | Temperature | Interior Dimensions |

| LTF2-11-17 | 1100°C – 1700°C (2012°F – 3092°F) | 16″H x 24″W x 24″D 5.5 Cu.Ft (0.15 Cu.m) |

| LTF2-14 | 1400°C (2552°F Max) | 16″H x 24″W x 24″D 5.5 Cu.Ft (0.15 Cu.m) |

| THF-1400-(6-12)- GAXP THF-1700-(6-12)- MP | 1400°C-1700°C | 6-12 Cubic Foot Furnace (~0.2-0.4 cu.m) Hearth up to 40″x 40″ Easy Waist Level Loading |

| Request Quote | ||

Box and Muffle Furnace Models

All MHI box and muffle furnaces feature rugged stainless steel construction, electronic controls capabilities, and MHI’s highly acclaimed heating elements. Our furnaces feature maximum operating temperatures of 1800°C and continuous operating temperatures of up to 1760°C. See the tables below to determine which model is best suited for your application.

| M-Series Box Furnace Models | ||

| Model Number | Temperature | Chamber Size |

| M14 | 1400°C (2552°F Max) | 12″H x 12″W x 16″D |

| M18-40 | Up to 1760°C (1800°C/3272°F Max) | 12″H x 12″W x 16″D |

| Other Size Box Furnaces | ||

| Model Number | Temperature | Chamber Size |

| Z18-40 | Up to 1760°C (1800°C/3272°F Max) | 6″H x 5″W x 6″D |

| H14-GAXP | 1400°C (2552°F Max) | 8″H x 7″W x 8″D |

| H18-40 | Up to 1760°C (1800°C/3272°F Max) | 8″H x 7″W x 8″D |

| N18-40 | Up to 1760°C (1800°C/3272°F Max) | 12″H x 12″W x 13″D |

Furnace Accessories

MHI now offers a variety of accessories to be used with our furnaces. Common accessories are clips, braided wire, hangers and other useful tools. To view these accessories, visit MHI Element Accessories or BuyMHI.

Furnace Controls

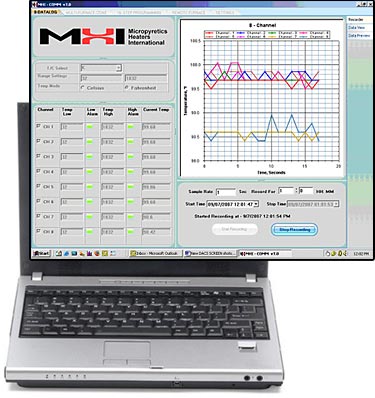

MHI offers remotely locatable electronic controllers with features such as overtemperature controls and programmable steps. In addition to standard electronic controls, MHI DACS allows for data logging and intricate step programming.

| MHI Furnace Controls | ||

| Many of MHI’s electronic furnace controllers feature multiple voltage inputs, overtemperature controls, programmable cycles and a number of other features. For more information about MHI’s control panels, Contact Us or See More Information. |  |  |

| Request More Information | ||

| MHI Data Acquisition and Control Software (MHI DACS) | |

| MHI Tube Furnaces are compatible with MHI DACS and Dacs 2 for furnace controls, 100 step programming, data logging and more. DACS also allows for remote furnace control, allowing one central location to control multiple devices. |  MHI DACS Software |

| Request More Information | |

Furnace Summary

MHI has pioneered several specialty furnaces. Standard furnaces are listed above. Many can be customized to the requirements of the user. Please click on a category below. Please also contact MHI if seeking to upgrade an old furnace with the modern GAXP® heating elements or fiberfree™ insulation. Rapid cooled sealed furnaces for Austempering and Martempering or similar heat treat conditions with accurate hold temperatures. Industries served include the industrial, heat treat, medical, commercial, R&D, innovation, packaging, instrumentation, aviation, transportation, refrigeration/air conditioning, ashing organic and inorganic samples, petroleum refining, gravimetric analysis, biomass, chemicals, forest products, iron and steel, food and beverage,cement, glass, fabricated metals, plastics and rubber products, reactors, alumina, aluminum, transportation equipment, foundries, computers, electronics, and electrical equipment, textiles, machinery, and all types of critical manufacturing.

|  |

Guide for furnace selection

| Lab Scale Furnaces | Industrial Scale Furnaces | Steam Ovens | Control Panels |

| Box Furnaces Bottom Loading Vertical Furnaces Horizontal Tube Furnace Tensile Testing Compact Slider Stackable Modules | Bottom Loading Tube Furnace Horizontal Tube Furnace Top Hat Furnaces Hybrid Furnaces Front Loading PC Concentrator Zapper | Recirculating Ovens Continuous Oven Custom Convective Ovens | Single Phase SCR’s 3 Phase SCR’s Electric Controllers Data Acquisition System MHI-8DATALOG Simple Gas Mixing System (automated) |

| Now Offering 1 Year Warranty on Heating Elements for Certain Classes of MHI Furnaces. Please contact MHI for full details. For easy purchase of spare parts visit our store – (spare parts) | |||