Electric Instant High-Temperature Steam Boiler

Use continuous steam methods for high productivity

Zero Emissions

Return to Main Steam Generator Page

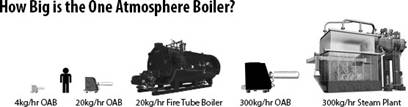

New models up to OAB 100-1000Kg/hr Variable steam, temperature, and back pressure models

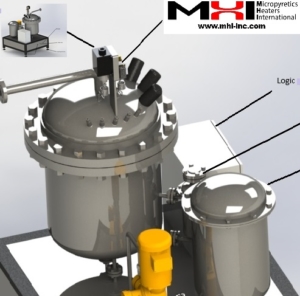

MHI’s OAB® is a 21st Century Steam Boiler. More Information.

MHI’s OAB® steam generator- Boilers are ideal for applications requiring on-demand steam, a small device footprint, and unparalleled efficiencies. OAB® devices have several advantages over traditional high-pressure steam boilers, including:

- No Feedwater Preheating – OAB® temperatures are available from 300°C to 1300°C without having to preheat feedwater as with traditional steam boilers.

- Zero Combustion/Emissions Process – OABs do not utilize combustion to generate high-temperature steam. Outlet-to-output efficiencies are well over 90%.

- Choose your pressure rating – no boiler inspections or certifications are required to operate an OAB in

Choice of back Pressures. Review the boiler regulations for your state.

Choice of back Pressures. Review the boiler regulations for your state.- Incredibly Small Footprint. The unit is easily locatable near the steam demand source.

- Plug and Play – No pipe routing, complicated installation, and easy hot-swap in case of device failure.

- Nearly Instant Steam – No waiting for your steam boiler to build pressure to get to temperature. No idling is required. OAB® devices produce superheated steam within minutes of a cold start.

The Patent Protected OABs offer higher temperatures, greater efficiencies, and significant process advantages over most steam boilers. For more information on how an OAB can improve your process, visit the links below or Contact Us.

For more information, see Superheated Steam or Electric Steam Boiler.

Steam Without the Wait

BoilerFree™ technology allows nearly instant steam production. Most MHI steam generators produce superheated in under a minute from a cold start. With various outputs and configurations available, MHI likely has a solution for your steam application.

Choice of back Pressures. Review the

Choice of back Pressures. Review the