Free Radiating Heating Coil & Panels

Round Coils and other shapes. 1400°C to 1900°C.

Made Possible With MHI Patents On Nanomaterials.

In Line MagnaCoil

Three such coil elements used in a three phase configuration will replace 1m long Silicon Carbide Rods in large furnaces. Plug in to 240V 3 Phase. These new HotCoilRods™ will not deteriorate by standard the “aging” process which causes deterioration in SiC rods. They offer greater power and longer life.

More Coils Below: Note that the power shown for the coil is for the free radiation use-mode. Vertical use-configurations and/or stress may reduce the effective use-temperature.

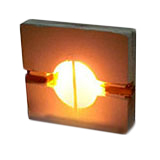

Cross Line MagnaCoil

MagnaCoils on the MHI webstore

Magna Coil Use Temperatures 1450C

MagnaCoil Part # n/Di/Lu/Lz | Coil Diameter, Di | Coil Length, Lz | Approximate number of turns, n | Coil Power, kW (Free Radiating Mode Free-R™) | Terminal Dimensions Type/Length |

1″ | 4″ | 8 | 2 kW | Standard Terminal | |

MagnaCoil MC-8/2/4/4 | 2″ | 4″ | 8 | 5 kW | Standard Terminal |

MagnaCoil MC-8/3/4/4 | 3″ | 4″ | 8 | 7 kW | Standard Terminal |

MagnaCoil MC-8/4/4/4 | 4″ | 4″ | 8 | 8 kW | Standard Terminal |

5″ | 4″ | 8 | 9 kW | Standard Terminal | |

MagnaCoil MC-16/6/4/8 | 6″ | 8″ | 16 | 14 kW | Standard Terminal |

MagnaCoil-3/MC-13/3/4/26 | 3″ | 26″ | 13 | 5 kW – Free-R 1.2 KW (insulated) | Standard Terminal |

MagnaCoil-6/MC-13/3/4/26 | 3″ | 26″ | 13 | 5 kW (30V) (insulated) Full Power | Standard Terminal |

n = Number of Turns Di = Inside Diameter of Coil Lz= Terminal Separation Distance Lu = 4″ Standard Terminal Length Request Quote for Round MagnaCoil Request Quote for Flat Heaters | |||||

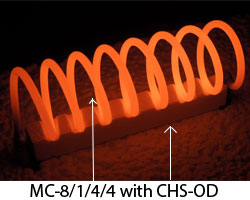

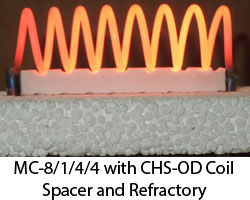

*Coil Accesories like te CHS-OD or equivalent spacers recommended for coil temperature uses exceeding 850°C

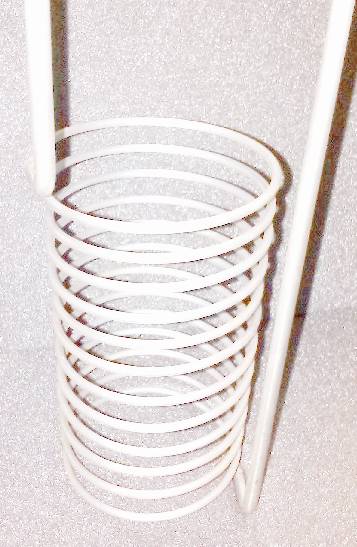

Inline MagnaCoil

MagnaCoil Part # | Coil Inside Diameter, Di | Coil length, Lz | Approximate number of turns, n | Coil Power, kW | Terminal Dimensions Type/Length |

| MagnaCoil | 3″ | 6 | 12 | 3-5 kW | Standard Terminal |

n/Di/Lu1-Lu2/Lz Lu2=Lz+Lu1 Lz~as given | |||||

Take me to the Insulated Coils Page Take me to the MicroCoil Page Take me to the MicroTube Page

Plug in MagnaCoil Part # Line voltage plug-in heating coils | Coil Diameter, Di | Coil Length, Lz | Approximate number of turns, n | Coil Power, kW (Free Radiating Mode Free-R™) | Volts |

1300C | – | 35″ | – | 5 kW | Hook Terminal 208-240V |

MagnaCoil-1.2-GAXP-120 1300C | – | 48″ | – | 3 kW | Hook Terminal 120V |

1000C | 0.6 | 12″ | – | 0.5 kW | Metallic 120 V |

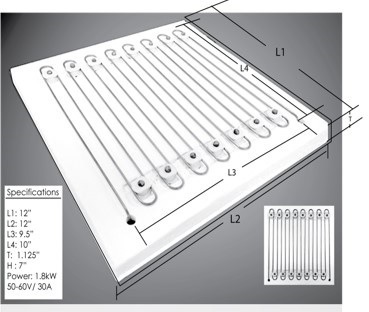

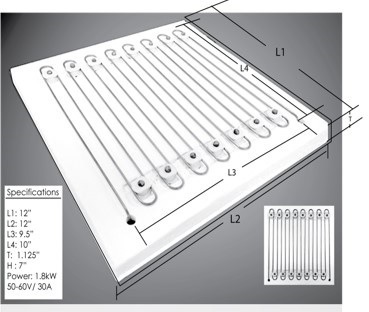

User Assembly Scalable Flat Heating Panels for High Temperature Use

Very small Magna Coil 6mm diameter

Please Click Graphics for Details.

| URP panels with Fractalin Pins and Holders | URP-V with Anti-sag MHI Materials and Technology |

|  |

For Flat Pancake Radiant Heaters Please Click Here

MagnaCoils™ – 1450°C Maximum Surface Temperature of Coil. The objective for the use of free radiating devices is to maximize the radiative POWER transfer from the heating elements.

If the heating element is used with insulation the objective of the user changes to obtaining a certain temperature inside the insulated region.

For either objective, one cannot exceed the rated temperature of the heating element (coil). The element use temperature may be further limited by creep and stress conditions including creep-fatigue interactions. Although general guidance on use is given, specific conditions are not known to MHI. Users are cautioned to use appropriate safety factors for the use- temperature rating.

If an insulated coil is preferred please see our Robust Radiator™ line of products now available with fiberfree™ high quality refractory enclosure.

Please use MHI Power Controls for the best performance. Please use Robust Radiators if using at the limit of performance.

Heating Element Temperatures (1450°C MC-MagnaCoil™ or 1190°C MCA-GAXP or IR)*.

Choose from Single Element, Flat or Round Cross-line, Hook, Inline Models or Inplane Terminals.

Also view Scalable Flat Glow Panels

| Heating Element Temperatures 1450°C (MagnaCoil™) Other configurations shown below Limitations on use configuations may apply because of coil-creep (movement during use) please Contact MHI. The use of spacers is recommended for vertical use/configurations. Spacers may not be available for Ultracoils. | |||

|---|---|---|---|

| Cross-Line In-Plane MagnaCoils™ The use of spacers is recommended | Inline Coils The use of spacers is recommended | Cross-Line Out of Plane Coils The use of spacers is recommended | |

|  |  | |

|  |  | |

|  |  | |

|  |  | |

Click here for pancake shape elements. | |||

Request a quote for coil elements.

Other configurations for MagnaCoil™ and UltraCoil™

|