Robust Radiator (RR) and Sleeve Heater Heating Modules are provided in six categories:

- Giant Sleeve Heaters > 60KW are used for oil heaters and gas pipelines. Contact MHI for BH-IMA.

- RHUL Models (scroll below) for up to about 1500°C (without end caps) and 1700°C (with end caps); both IRHUL (inline) models and RHUL (cross line) models are available.

- MRCL Models (scroll below) for up to about 1300°C. Cross-Line MRCL and Inline Models I-MRCL. Custom Split RRs are offered. Split RRs are restricted in power density.

- GRR & Small Sleeve Models – High Uniformity Plug-in G-Robust Radiators (GRR) and Sleeves for 1250°C/1300°C user applications

- Industrial Size Robust Radiators: GiantHeat™ GlowPanels (custom)| MRCL-GA6125-24

(6-8″ diameter)| Custom Stackable (36″ diameter)

(6-8″ diameter)| Custom Stackable (36″ diameter)

- High Heat Flux Devices 100kW/m2. Please contact MHI.

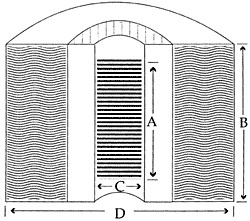

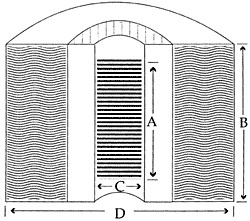

All Robust-radiator modules are specified with the dimensions in the schematic below. Please read the power in the respective tables below.

Why are they long-lasting? MHI Robust Radiator is enclosed in a special RR Fractalin Ceramic, which displays extraordinarily low expansion or distortion. This is the secret of its longevity.

For A, B, C & D Dimensions, See the Diagram Below. For Multi-Zone Models, RHUL type (1500C+), MRCL (1350C), GRR (1300C), and Stack (please scroll down)

Several Models are priced on the MHI Web Store

RR Dimensional

| Please see the diagram above to specify the Robust Radiators |

| Please scroll below for various types, including Inline and Split Radiators |

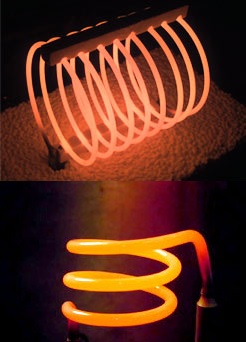

Heated Ultra and Magna-Coil inside a Radiator

Robust Radiator™ Applications. To estimate approximate power requirement. Click here.

The Robust Radiator™ uses include zone-heating, crucible-heating, pipe-heating, or other applications requiring high temperatures and high versatility.

| Suggested Uses | |

| Multi-Zone Furnaces | Material Testing Fluid heating |

| Tube Heating | Crucible Melting |

| Annealing | Crystal Growth |

Wafer Productions Semiconductor purge gas heating Ink preheating systems • | Sintering and Food cooking equipment |

| Metal Melting. | And Many More Uses Hemo-dialysis fluid heating |

The JOULE (J) is a commonly used unit of energy. The BTU is also a unit of energy. Another typical unit of energy is KWhr (Kilo-Watt-Hour). See conversion tables.

RHUL Robust Radiator 1500°C-1700°C

|  |  |  |

Robust Radiators on the MHI Web-store

Linear Radiator on the Web Store

| Standard Robust Radiator™ Configurations (High temperature – nominal range 1500C-1700C with end caps) For A, B, C & D, Please Refer to the Dimensions in the Diagram | |||||

| Model # | Maximum Power (Watts)* | Heated Length (A) | Overall Length (B) | ID (C) | OD (D) |

| RHUL-MP1125-6 | 825 | 4 in | 6 in | 1 in | 5 in |

| RHUL-MP2125-6 | 1425 | 4 in | 6 in | 2 in | 6 in |

| RHUL-MP3125-6 | 3000 | 4 in | 6 in | 3 in | 6-7″ (inch), depending on the shell. |

| RHUL-MP4125-6 | 3200 | 4 in | 6 in | 4 in | 6-8″ (inch), depending on the shell. |

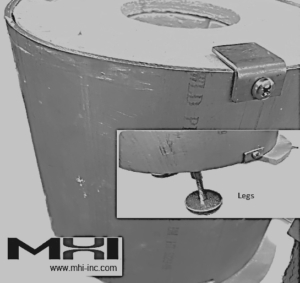

Sleeve Heater

Sleeve Heater

Use for individual zone heaters in zone refining operations

| Model # | Max Power (Watts) | Heated Length (A) | Overall Length (B) | ID (C) | OD (D) |

| SLH1.5 | 350 | 0.25 in | 2 in | 1.5 in | 5 in |

| SLH-3.0 | 800 | 0.25 in | 2 in | 3 in | 6.5 in |

GRR & Sleeve Models – High Uniformity Plug-in G-Robust Radiators (GRR) and Sleeves for 1250°C/1300°C user applicationsHigh Uniformity G-Robust Radiators (GRR Models) for 1250°C/1300°C |

| GRR Model | ID (in) | L (in) | Power (kW) (Nominal) | Control Panel | Volts** |

| GRR1(3)-110 | 1 | 3 | 1 | IBPAN-110 | 115/120 |

| GRR2(2)-120 | 2 | 2 | 1.4 | IBPAN-110 | 120 |

| GRR2(4)-220 | 2 | 4 | 2.5 | IBPAN-220 | 220/230 |

| GRR2(10)-220 | 2 | 10 | 6 | IBPAN-220 | 220/230 |

| GRR 3(3) -120 | 3 | 3 | 1.5 | IBPAN-120 | 110/1200 |

| GRR 3(5)-220 | 3 | 5 | 3 | IBPAN-220 | 220/230 |

- Click for GRR & Sleeve Models – High Uniformity Plug-in G-Robust Radiators (GRR) and Sleeves for 1250°C/1300°C user applications

** Plugin voltage indicates closest IBPAN preference. The GRR unit temperature, amperage (current), or power cannot be exceeded in any user configuration. Configuration of use changes with end caps, load, control thermocouple flow placement, and insulation extent. Please check the manual for maximum element temperature that cannot be exceeded.

RR Dimensional

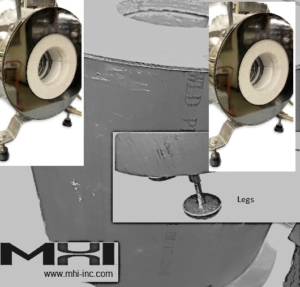

Inline Robust Radiator

Specifications (Inline is built to specification, minimum order may be required)

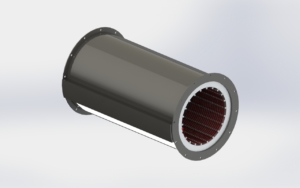

MHI’s Inline Robust Radiators™ are versatile, high-temperature heating devices capable of reaching temperatures up to 1700°C. They can be used in a variety of environments and positions. The MHI Inline Robust Radiator™ is available with optional end caps to achieve maximum chamber temperatures and an optional stainless steel shell that adds to the connection accessibility. You can order by part number or inquire about special needs. MHI will be happy to provide a personalized recommendation that will fit your needs.

| Applications

|

BPAN-O-PLUS Control Panel and UL model

| |||||

| Inline RR Model # | Max. The temperature of the Heating Element | (A) Heated Length | (B) Overall Length | (C) ID | (D) OD |

| Magna- IMRCL-GA1125-4 | MagnaCoil™ (Max. Temp. in RR ~1400°C) (~1 KW Power) MagnaCoil™ (Max. Temp. in RR ~1400°C) (~1.5 KW Power) | 2.5″ 2.5″ | 4″ 4″ | 1″ 2″ | ~6.5″ ~6.5″ |

| Ultra-IRUHL-MP0625-4 | UltraCoil™ (Max. Temp. in RR ~ 1700°C) (~1 KW Power) | 2″ | 4″ | 0.5″ | ~6.5″ |

| Magna- IRHUL-MP1125-8 | UlltaCoil™ (Max. Temp. RR ~1700°C) (~3.5 KW Power ) | 6″ | 8″ | 1″ | TBD |

| **Standard terminal length is about 1″ protrusions from the ceramic face. Aluminized for UltraCoil Model. SS Models have Stainless Steel Shell Enclosures. The temperature of the part may vary with thermal load; For IRHUL, the temperature rating is with end caps. See the illustration above for the dimensions and nomenclature of A, B, C, and D. | |||||

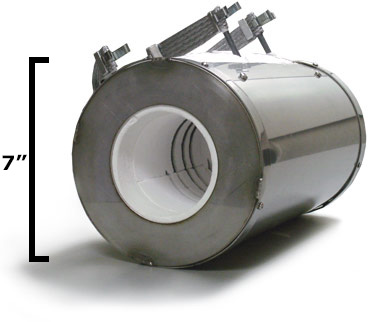

MRCL Robust Radiator 1300°C

Robust Radiators on the MHI Web Store

For A, B, C & D Please Refer to Dimensions in the Diagram

| Model # | Maximum Power (Watts)* | Heated Length (A) | Overall Length (B) | ID (C) | OD (D) |

| MRCL-GA6125-24 (SS casing) | 12000 208-240V plug in | 20 in | 24 in | 6 in | >10 in |

| MRCL-GA1125-6 | 825 | 4 in | 6in | 1 in | 5 in |

| MRCL-GA5125-6 | Call | 4 in | 6 in | 5 in | 9 in |

| MRCL-GA2125-6 | Call | 4 in | 6 in | 2 in | 6 in |

| MRCL-GA4125-6 | Call | 4 in | 6 in | 4 in | 8 in |

| MRCL-GA3125-6 | Call | 4 in | 6 in | 3 in | 7 in |

| MRCL-GA6125-24 (SS casing required) | 12 kW (High Power Models) | 20 in | 24 in | 6in | ~10 in |

The MRCL-GA6125-24 is2a 220V/230V/240V plug in

| User Submitted Photographs | |

Robust Radiator™ as a Crucible Heater |

Please review Testimonials |

Testimonials

Some Of Our Many Satisified Customers Using the Robust Radiator

M.O., National Laboratory

“…the heating system that you helped me set up is working great!”

E.B., University

“…Robust Radiator is working perfect as a Crucible heater.”

L.C., Canada

“We just received the elements… they look great.”

Dave J, Washington

“I am very pleased with its performance. We feel it can be useful for a lot of our projects.”

Unlike fully finished furnaces, Robust Radiators™ are products that are typically components of a larger system. Please be fully conversant with the electrical and safety requirements during installation and use, including the use of connectors. Please call MHI at 513-772-0404 when in doubt. Contact MHI for custom solutions.

Split Radiator

Split Radiator – Split Radiators offer Lower Power. MRCL class only. | ||||||||

Only as Special Order Custom Units. Total Watts 2 Halves- 200W (C= 1″ x A= 1″ ) (1100C) Split Radiator with Shell is special make only e.g B=4″ and C=0.5″. Power~200W.

Split Compact Furnace

| ||||||||

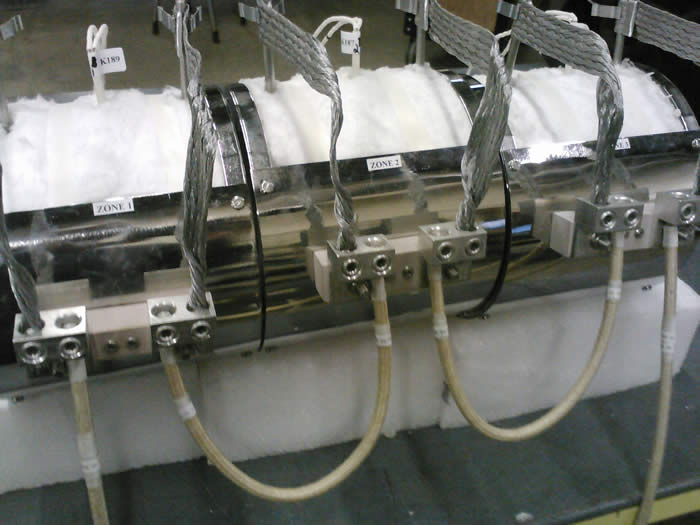

Unlimited Power with Multiple Zones

- High power density

- Volume pricing

- Non-toxic fiber-free enclosure

- Match to your line voltage if required

- Full line of electronic controls available

- Rapid Delivery

Live Customer Support by phone (513-772-0404) or email. . Typical single and Multi-zone configurations are shown below. Terminal connectors are shown for each-zone. End-caps and all other accessories available – see section on Robust Radiators.

|

(KiloJoule) = 0.9485 BTU=0.0002778 kWhr

The Watt (W) is a unit for power i.e. the energy used (or supplied) per unit time. 1 J/s (Joule per second) = 1 W (Watt)

Power-Units Conversion 1kW (KiloWatt) = 3414 BTU/hr

How much energy and what kind of power will be suitable for your heating application? The estimators in the link above may be used to calculate the energy required for common processes. Then by choosing a time over which the energy will be used one can calculate the best power required from the heater.