MHI Product Links

Decarbonization Equipment and Costing Overview

MHI systems adjust to optimize the energy required by drawing only the necessary power. An underpowered system will struggle to get to the temperature.

Superheated Steam Generators|Microheaters | Airtorch®| Heating Elements | Furnace and Furnace Accessories | Thermoplate| Microheater | Robust Radiator™ | Fiber Heater | Silicon Carbide Elements | Plasma |Nano Products | Electric Control Panels

Calculators

Energy Efficiency from an Electric Airtorch.

GAXP® Furnace Element Calculator

Calculate 3 Phase Power, Voltage, and Resistance

DPF and TA Model Flow vs. Power. Useful Tips for Airtorch Selection.

ROI and Monthly Payment Calculator

Watt Calculator – Fun with Energy and Power

Steam Calculator and Superheated Steam

Airflow and Airtorch™ Calculator

Information and Tutorials (Conceptual help tutorials)

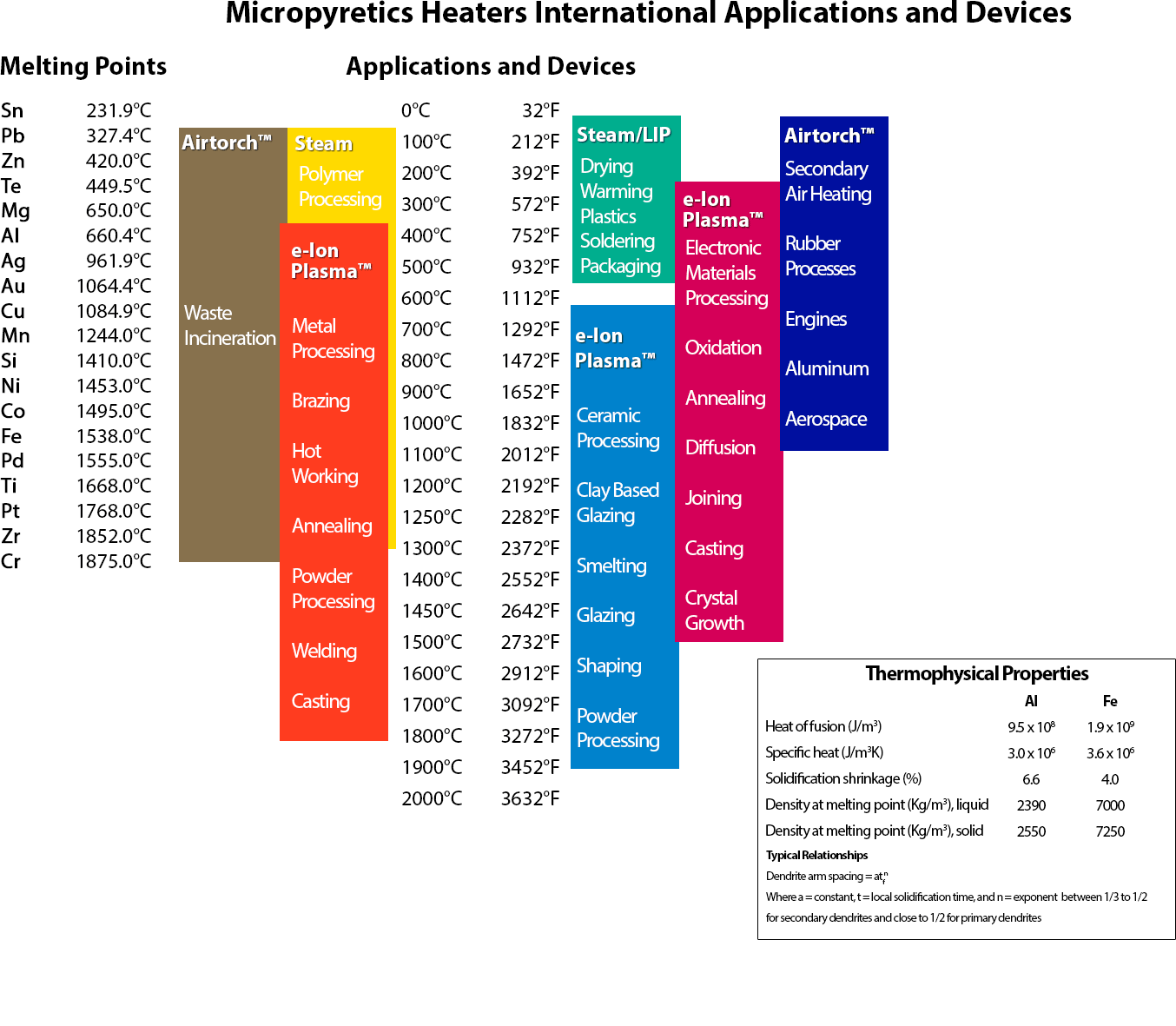

Applications of High-Temperature Furnaces, Steam, Airtorch Systems.

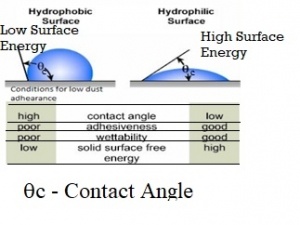

Basics of Surface Smoothing, Peening, and Deburring

Economic of higher temperature deployment.

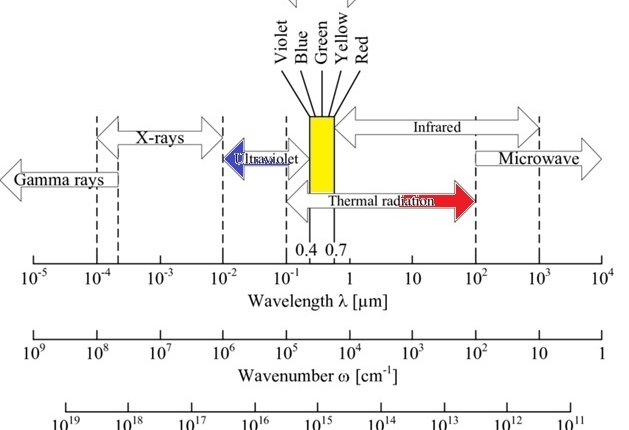

Basics of Radiation Power Transfer

Compare Laser, Electron Beam, and Sunlight

Engineering Units Conversion Calculator Page

Important Concepts in Thermodynamics

Properties of Gases and Moist Air with Temperature.

Review of Equilibrium Constant and Production Speed Calculator

Free Calculator for Calculating Emissions from Natural Gas and Other Fossil Fuels.

How does one use the Cascade e-ion for high-productivity processes?

Applications (more added periodically)

Compared with Laser, Electron Beam, and Sunlight

Clean Electric Flame compared with Combustion Flame

Highly improved tool bits and drill conditioning made it easy

Bending and shaping all types of glass

Seasoned cast iron is not anti-stick. How to make anti-stick cast iron.

How can we easily make the highest hardness material in the world with cascade e-ion?

How much CO2 can I save by going electric? See more…(pdf format)

Links for Antimicrobial Steam Cleaning?

(from https://bayzi.com)

Helpful Constants

A global leader in smart power industrial device technologies. Meeting the global grand-challenges for our customers

A global leader in smart power industrial device technologies. Meeting the grand global challenges for our customers.

| Energy Conversion | kJ mol-1 | kcal mol-1 | eV | cm-1 |

| kJ mol-1 | 1 | 0.23901 | 1.0364×10-2 | 83.59 |

| kcal mol-1 | 4.184 | 1 | 4.3363×10-2 | 349.75 |

| eV | 96.485 | 23.061 | 1 | 8065.5 |

| cm-1 | 1.1963×10-2 | 2.8591×10-3 | 1.2398×10-4 | 1 |

wavenumber wavelength and frequency chart

| Universal Constant | Units and Value |

| h (Planck’s constant) | 6.626075 *10-34 J s |

| kB (Boltzmann’s constant) | 1.38065 *10-23 J K-1 |

| NA (Avogadro’s number) | 6.022136 *1023 mol-1 |

| c (speed of light) | 2.9979245 *108 m s-1 |

| ao (Bohr radius) | 5.2917724 *10-11 m |

| e (charge of an electron) | 1.6021773 *10-19 Coulomb |