A new method for treating tool bit surfaces that makes an HSS tool bit perform better than a CVD-coated bit.

Less machine chatter and reduced galling enhance life and create a smoother cut, which is always a good outcome.

Quasi-R® and GoldenBlue® treatments reduce friction, improve machining outcomes, and reduce energy waste.

Users report over a 40% reduction in the coefficient of friction. Improved hole circularity during drilling.

Easy multi-color tool-bit reconditioning with the cascade e-ion family of machines.

MHI offers a GoldenBlue® and Quasi-R® for tooling, parts and surfaces that need to be conditioned. This method provide greater hardness, increase wear resistance, low friction that extend life for a variety of materials and alloys.

What is GoldenBlue®?

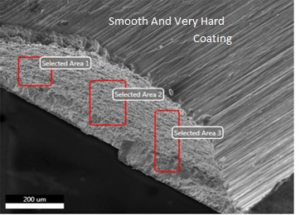

The Cascade e-ion Plasma is a versatile machine that may be used to impact the surface texture and roughness of metals (Cascade e-Ion source), ceramics (Cascade e-Ion EIZ), or soft plastics (e-Ion LIP). With the e-Ion Plasma machine, one may rapidly “deburr” or create new surfaces, depending on the ions used and other correctly set conditions that change for specific alloy surfaces and temperature. Nanoscale features of texture and porosity that are now known to be essential for surface bioactivity or roughness can now be engineered. Sometimes, trial and error experimentation may be involved regardless of whether it is HSS, titanium, steel, cobalt, or PEEK alloy. Contact the manufacturer, MHI. The in situ-growth coating that forms on exposure to the cascade e-Ion beam very often has low lubricity and high surface hardness. Saves the energy of machining. It saves tool resources and offers many more benefits. Improved coatings on high-speed machine tools, cutting knives, blades, and even recoating thin razor blades when appropriately coated. Transform and reuse (recoat) at will, re-sharpening when possible. To prolong tool life, identify the signs of wear like abrasion, fracture, chipping, etc.. Both thermal and mechanical stresses cause tool wear, with heat and abrasion being the primary culprits. Reducing heat generation during machining by lowering the friction adds considerably to life. This can be done with messy oils or using a GoldenBlue®-treated surface.

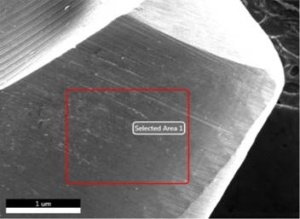

GoldenBlue® is the trade name for service and multi-color high-value surfaces created by the Cascade e-ion—ultra-hard and ultra-smooth. A low coefficient of friction ~0.1 ( number depends on surface) with sharp edges is obtained. A hardness of about 13 Gpa and low friction is obtained. A hardness of about 13GPa is equivalent to a Rockwell C of about 75 Rc; however, the Rockwell C scale is not meant for such high hardness or coatings. The Cascade e-Ion machines offer easy nano-nitriding/oxynitride of tungsten cobalt, stainless, and titanium alloys (almost all transition metal alloys) with just air use as the process gas (no toxic gas or vacuum treatment).

An extensive surface area treatment, when required, does not present a problem. For example, if railway tracks were to be made by GoldenBlue® treatment, it would not present a problem for size. Consider automobile parts, from engine parts to shafts and gears. When you purchase a machine, you are freely enrolled in the expanding cascade e-ion group knowledge base. The coatings may be beneficial for bolts and nuts that seize during operations, i.e., for making non-seizing surfaces for automobiles, aircraft, and other high-temperature engine parts like bolts, even for corrosive outboards. Each situation may be different. However, MHI will happily do limited free parts for your verification while this offer lasts. Please contact MHI for details. It is a new type of heat treatment with vast possibilities. MHI has introductory prices well below lasers, large vacuum and gas furnaces, or vacuum ion nitride.

| Coating | Oxynitride or Carbo-oxynitride variations |

|---|---|

| Color | GoldenBlue® is a trademark that signifies the multi-color hard in situ coating. |

| Structure | Functionally Graded |

| Microhardness | >3000 Vickers (nano) as an example. |

| Applications | It is one of the best for its high hardness, low coefficient of friction, improved drilling speeds, and other benefits, such as less heat and less chatter, depending on the substrate. It is used for stainless steel, hardened die steel and even ceramics. |

Try GoldenBlue®. The process is simple: Immerse or move the part in or under the special CleanElectricFlame™ produced by the Cascade e-Ion™.

Process for about ten seconds (for an inch or so thickness part). For a typical HSS drill bit, one should expect about a 15% tool life improvement per hole over the uncoated (such an improvement is in the same range as the regular TiN Ior Fe-Ti-Al-N-W-C type coating for HSS commercial coatings, at least as noted in our limited trials). The total life improvement could almost double (depending on part size and type). The GoldenBlue® – B treatment offers even better expectations of about a 25% improvement in speed over a regular HSS-uncoated. These results are typical and may vary with the drill.

Improve carbide bits: Yes, coating is feasible on end-mill carbide inserts. You can also coat many punches, dies, and other surfaces in situ.

Please do not hesitate to send us your specific tool or typical surface for trials so we can treat it for you. We can also determine if your tool bit may be reconditioned to higher grades of GoldenBlue®. A treatment charge is required, which is very nominal.

Early stage, first-time use customer testimonial: “We ran one of the inserts on 17-4 stainless steel on our CNC lathe……..The coating did seem to make a difference. I would say at least 15 to 20% better than without it. I ran the small insert on 1045 steel. Bored 40pc with two passes for each bore. One thing I noticed right off the bat was the coating gave an improved finish over a standard insert finish. I did not have to change the insert and finished all 40 pcs without the tool breaking down!”

MHI to Customer: Thank you so much for sharing the result.

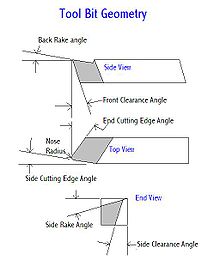

The available technology for surfaces and tool bits is changing rapidly. How does one compare drills and other such tools? The following checklist may assist your evaluation.

(1) For the same sharpness (radius of the edge), compare drill or cutting time; (2) For the same sharpness, compare the life of the tool before it begins to screech or leave behind burns; (3) compare the overall cost of the value addition, i.e., compare the improvement per unit cost including the cost of the of tool, cost of operations, cost of change/wait period, (4) determine whether the tool may be reused after coating and or after re-sharpening, and (5) if applicable, whether a sharpened tool may be recoated.

With the cascade e-Ion processed tools, we saw better drill speed (we could double the speed in a drilling experiment), improved sphericity of holes, cleaner breakthroughs, and smoother tapping control for tapping tools. All this results in more energy efficiency during manufacture and drilling/tapping because of the Goldenblue® treatment/coating.

Is there a simple way to tell if the Cascade e-Ion Plume treated part is smoother? Less noise indicates smoothness for a ball bearing, roller bearing, or other part.

How do you know that the surface is harder (or has a higher modulus)? A Vickers hardness test or bounce a ball bearing and watch if it bounces higher than the non-treated.

With the Cascade e-Ion processed surfaces, we saw improved smoothness as measured by the chatter quality of the cut, with no seizing and less heat generation. Thus giving confident and longer-lasting tool expectations.

|

Common high-speed steel HSS composition grades (by %wt. nominal) |

||||||||

|

Grade |

C |

Cr |

Mo |

W |

V |

Co |

Mn |

Si |

|

T1 |

0.65-0.80 | 4.00 | – | 18 | 1 | – | 0.1-0.4 | 0.2-0.4 |

|

M2 |

0.95 | 4 | 5 | 6.0 | 2.0 | – | – | – |

|

M7 |

1.00 | 4 | 8.75 | 1.75 | 2.0 | – | – | – |

|

M35 |

0.92 | 4.3 | 5 | 6.4 | 1.8 | 5 | – | 0.35 |

|

M42 |

1.10 | 3.75 | 9.5 | 1.5 | 1.15 | 8.0 | – | – |

Save energy. Repair rapidly at will. Enjoy improved performance.

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA