Bottom Loading/Opening Furnace – High Temperature

H18-40 Bottom Loading Furnace

Motorized Bottom Loading Furnace Features

MHI’s extensive line of bottom-loading furnaces has its class’s highest uniformity and energy efficiency ratings. They are best for batch production, firing ceramics, ferroelectric, net materials, and glass melting. Our bottom-loading furnaces also feature a smooth electronic hearth lift, purge gas inlet options, and various customization possibilities.

- Bottom loading furnaces are the most uniform, with heating elements on all four sides. Optional production streamlined loading system (OPSL) available.

- Smooth electronic hearth lift.

- Purge gas inlet option available.

- Chimney exhaust port option available.

- Reliable production units.

- Most MHI bottom loading furnaces are transformerless, reducing weight and size.

- Small footprint.

- They are designed for modern production practices and optimized for batch production.

- They are used for firing ceramics, NPT and dielectric materials, ferroelectric materials, glass melting, and several other applications.

- Contact Us for information on customizing production furnaces for process manufacturing and glass melting.

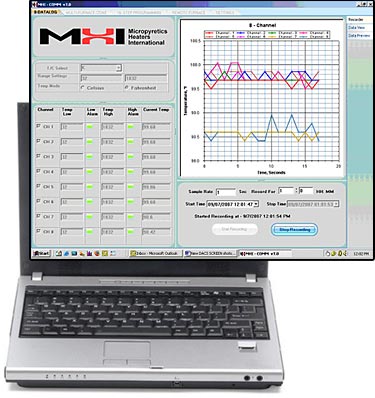

- The small footprint control panel is remotely locatable, as shown above.

- Compatible with our low-cost Data Acquisition and Control Software.

- Packing and Packaging Materials – International Standards

- HIGH-QUALITY MP1850 HEATER

- INSIDE AND OUTSIDE WALLS are HIGH-GRADE STAINLESS STEEL

- FIBERFREE™ INSULATION

- ELECTRIC HEARTH

- EASY NEVERDOWN RATES

- SCR CONTROLLED TRIPAN with UL/CE CONTROLLERS AND AESTHETIC PANEL LAYOUT

- SEVERAL OPTIONS ARE OFFERED FOR HEARTH PLATES

Bright LED Display Lights &

International Packaging Materials

The chimney exhaust port is a standard MHI furnace option.

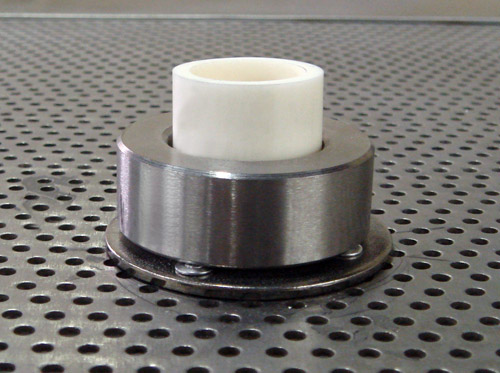

The ceramic tube is made out of NanoFractalAlumina™ with high thermal shock resistance.

Optional chimney exhaust port and other gas feature or vacuum feature shown with standard perforated furnace top.

Bottom Loading Furnace Models

All MHI bottom loading furnaces feature rugged stainless steel construction, electronic control capabilities, and MHI’s highly acclaimed heating elements. Bottom loading furnaces feature excellent uniformity with heating elements on four sides. Our furnaces feature maximum operating temperatures of 1800°C and continuous operating temperatures of up to 1760°C. See the tables below to determine which model best suits your application.

| Model Number | Temperature | Interior Dimensions |

| H14BLE | 1400°C (2552°F Max) | 8″L x 9″W x 9″H |

| H18-40BLE | Up to 1760°C (1800°C/3272°F Max) | 8″L x 9″W x 9″H |

| H14BLE 12 x 12 | 1400°C (2552°F Max) | 12″L x 12″W x 12″H |

| H18-40BLE 12 x 12 | Up to 1760°C (1800°C/3272°F Max) | 12″L x 12″W x 12″H |

| H14BLE 15 x 15 | 1400°C (2552°F Max) | 15″Lx 15″Wx 15″H |

| H18-40BLE 15 x 15 | Up to 1760°C (1800°C/3272°F Max) | 15″L x 15″W x 15″H |

| H14BLE 18 x 18 | 1400°C (2552°F Max) | 18″ L x 18″W x ~16″H |

| H18-40BLE 18 x 18 | Up to 1760°C (1800°C/3272°F Max) Footprint – call MHI | 18″ L x 18″W x ~16″H |

| Request Quote | ||

Bottom Loading Furnace Applications

MHI’s bottom loading furnaces feature a small footprint, allowing for a diverse number of applications. Because of their size, we have had comments from users about our BLE’s being great for batch production. Contact Us to see which furnace is best for your application.

Bottom Loading Furnace Suggested Uses

- Industrial Furnace

- Glass Melting

- Melting Furnace

- Sintering Furnace

- Ceramics

- Ferroelectric Applications

- Heat Treatment Furnace

- Dielectric Materials

- Melting Aluminum

- Annealing Furnace

- High Temperature Oven

- Tempering Furnace

Furnace Controls

MHI offers electronic controllers with features such as overtemperature controls and programmable steps. In addition to standard electronic controls, MHI DACS allows for remote furnace location, data logging and intricate step programming.

| MHI Furnace Controls | |

| Many of MHI’s electronic furnace controllers feature multiple voltage inputs, overtemperature controls, programmable cycles and a number of other features. For more information about MHI’s control panels, Contact Us or See More Information. |  |

| Request More Information | |

| MHI Data Acquisition and Control Software (MHI DACS) | |

| MHI Tube Furnaces are compatible with MHI DACS for furnace controls, step programming, data logging and more. DACS also allows for remote furnace control, allowing one central location to control multiple devices. |  MHI DACS Software |

| Request More Information | |

Furnace Accessories

MHI now offers a variety of accessories to be used with our furnaces. Common accessories are clips, braided wire, hangers and other useful tools. To view these accessories, visit MHI Element Accessories in the easy purchase MHI webstore.