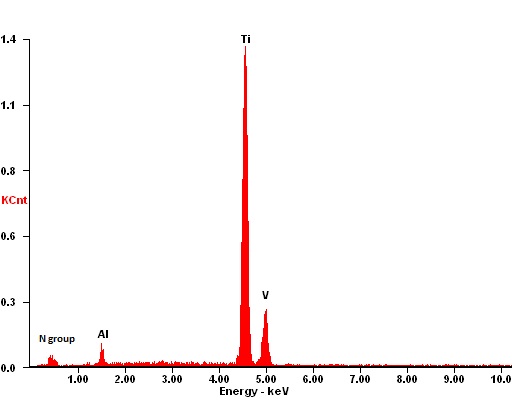

Exposure to an air-based Cascade e-Ion plume produces a delicate gold color coating (shown below for a biomedical insert screw) on biomedical Ti/6Al/4V alloy with the following EDAX spect m. Coating creation and refurbishment are greatly simplified. Use just air for input gas as described below for the EDAX result, or use nitrogen gas or forming gas as required.

Almost all customers considering the Cascade e-Ion for an application or to GoldenBlue® request the Deburring of parts.

The Cascade e-Ion Plasma™ is used for Titanium Alloys (including multilayer graded peening), Co-Cr-Mo type biomedical alloys, stainless steel alloys, high-density plastics, dental alloys, gold alloys, superalloys, or for surface and other conditioning of Nitinol, Ni-Ti, Ti-Al, Ti-6-2-4-2 (such as Ti-6Al-2Sn-4Zr-2 to 6Mo) shapes castings, forgings, and many others.

Nitriding Ti-6Al-4V with the Cascade e-Ion Plasma™ improves Ti6Al4V surface properties for biomedical applications. Please contact us for your specific application. MHI offers complex part manipulators, from robotic arms to continuous belts.

Cascade e-Ion Models are applicable for oxynitriding and surface coatings. De-e-Ion machines are used for nanoporous surfaces.

Other uses of transition metal oxynitrides and rapidly forming very smooth hard coatings with the Cascade e-ion include:

Tool-bit Industry products include drills, end mills, broaching tools, rams, inserts, cutting tools, deep draw, cylinders like master pumps, slides, bearing rollers, and ball bearings.

Automobile or sea-borne vehicles from use in related steel, aluminum, and plastic industries that include turbines, shafts, spindles, gears dies, extruders molds, bearings, crankshafts, camshafts, gears, pistons, cylinders, springs and valves, rings, dies and molds.

Molds are used in casting and plastic and die-casting industries.

Forging and forming industries include forging and pressing, including cold forging, shape forging for impressions, open die forging, hammering, and bending.

The smoothness (low coefficient of friction) properties are significant for bearings and bushings even when sealed.

MHI finds that chromium, iron, and titanium (transition metal) oxy nitrides are particularly useful compared to regular nitrides as they work towards lubricity, low wear, low coefficient of friction, low galling, and a beautiful surface look. fl—the cascade e-Ion plates ions continuously in r. Please take advantage of this feature and be to your market first.

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA