- Simple and Elegant. Multiple walls. Heat contained and designed by thermal leader MHI. Simple lift-off. Lightweight.

-

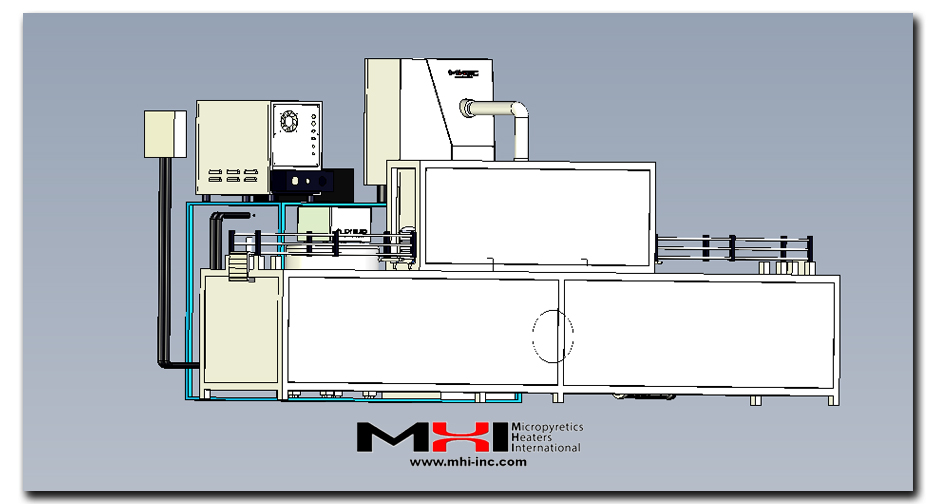

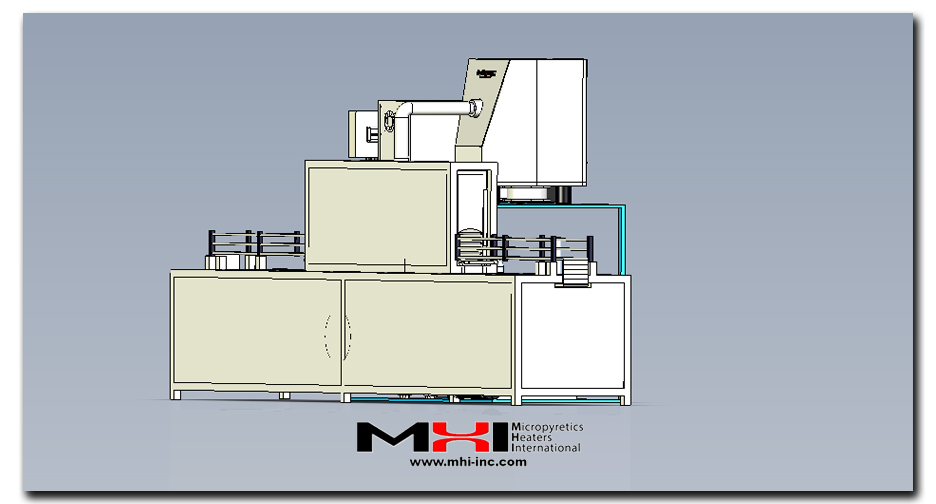

Easy Tunnel Design from the High-Temperature Leader for Shrink-Wrap, Clean for Removing Bacteria or Condition Cotton Textiles

Feeding into SWE machine. Adding moisture to cotton fiber or shrink-wrap CPG.

- The powerful OAB generator generates steam. Energy-efficient.

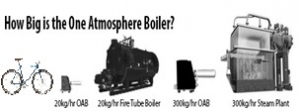

- Example: What is the yearly Operational Benefit of an MHI 16kW steam generator over a 300kW traditional boiler?

- Turn OAB®on and off. No need to idle. Move OAB® across various SW lines if required. Save energy and reduce belt wear.

- They are now offered with GOLDEN BLUE smooth oxynitride high lubricity.

- Easy adjustment by flaps and height adjusters for the entire tunnel when required.

- Intuitive Design – Graduated indicators simplify setups and adjustments.

Overcome the energy disadvantage of traditional 150kW- 300 kW (15-30 BHP) Boilers. Use with 12 kW OAB® steam. Reduce your cost per label.

Overcome the energy disadvantage of traditional 150kW- 300 kW (15-30 BHP) Boilers. Use with 12 kW OAB® steam. Reduce your cost per label.

Rapid labeling has never been more accessible, even for pre-filled bottles with unusual curvature. Transitions to high ~90% savings are feasible.

What Are Shrink Film and Textile Materials Made of?

Common Problems with Standard Hot Air and Pressure Boiler Steam

Download the Brochure for Steam Tunnel

MHI is a leader in high-temperature hybrid designs for batch and continuous loads. Contact MHI for simple design criteria for continuous loads from textile, packaging, and food cleaning to metals. Rapid labeling has never been more accessible, even for filled bottles with unusual curvature. The transition towards high 95% savings in energy and water is feasible even with complex bottles.

Explanation of VPI (Value Performance Index) for cost comparisons.

Learn more about OAB® and its applications

How do Temperature and Pressure Impact a Steam Reaction?

OAB® Compared to Traditional Boilers

Steam Calculator, Productivity Enhancement and FAQ’s |Physical Properties of Moist Air/Gas | What are Steam and Humidity?

What are the Common Problems with Boilers For the Packaging Industry

Productivity Enhancement and FAQs

Physical Properties of Moist Air/Gas

Want to find out how MHI can help you meet your steam needs? Fill out a quick questioner and we will help find a solution to meet your needs.