MHI offers patented superheaters for the OAB® as well as for existing boilers.

Home Page for Steam Generators.

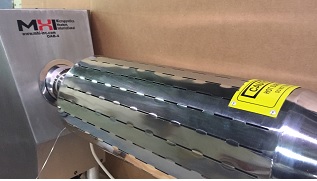

New: The SC-4 superheater can be purchased in the MHI store.

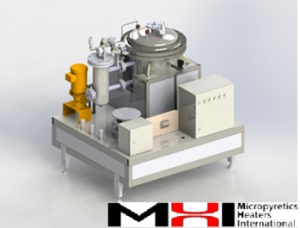

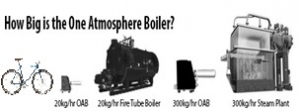

We recommend considering a high-temperature OAB rather than superheaters for existing boilers, as it may be the lower-cost solution. Units that can produce up to 3 tons/hr. of steam are available.

OAB® Superheaters for OAB-4 and OAB-12. Superheaters for MHI Steam Generators.

| MHI also offers superheaters for existing boilers. Superheaters for Pressure Boilers. Choose MSC or GSC models. Limited Availability. Requires Design. Please contact MHI to raise the boiler steam temperature to over 800°C. Please provide full details of your boiler and its ability to provide high-quality (i.e., no water droplet) steam. Alternatively, please click on GHGA or OAB. Please specify the flow rate in Kg/hr, inlet temperature, outlet temperature required (KW if known), and the pressure rating required of the superheater. New: The SC-4 superheater can be purchased in the MHI store. |

| Click for examples of applications | Click for examples of applications |

- We prefer you to start with an MHI steam generator because its characteristics are known to us; however, if you already have an existing boiler, we can most likely design a superheater for you. Please contact MHI to raise the boiler steam temperature to over 800°C. Please provide full details of your boiler and its ability to provide high-quality (i.e., no water droplet) steam.

- OAB® and other MHI steam generators feature BoilerFree™ technology. The steam output is approximately 40m/s. Additionally, steam is self-propelling in most instances, and superheating is an advantage.

- Steam Generators can be used for chemical (process and labeling), mechanical, or heating purposes. MHI provides enhanced energy efficiency and an improved control system.

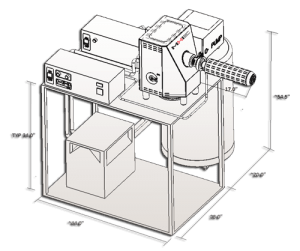

- Design help is available online. High-temperature steam generators are simple to install and use. The OABs can usually be installed immediately adjacent to the application.

- OAB® steam generators feature On-demand steam from a cold start within seconds to minutes (for OAB 4 and 12 models, it takes about ten seconds for even the first run). The device does not produce CO/CO2 or NOx toxic gas by-products.

- Enjoy dry and clean steam of high quality.

- Experience significant cost savings in energy, a better product, and operational ease with the on-off type feature. Relocate or change the layout at will.

- MHI is an experienced company that manufactures small to large power control panels. sometimes, manifolding assistance is provided h manifolds.

- MHI steam solutions are provided with units designed to simultaneously offer the high temperature-high enthalpy steam of the traditional OAB® and carry an add-on steam output for a high-pressure steam line when required. This feature provides considerable universality. The high-pressure attachment can be added to one line of the BPE attachment. Please contact MHI to discuss the add-on price for high-temperature steam (up to 1300°C when chosen ), high-pressure steam (up to 4 bar), and hot-water lines operating simultaneously when required. Most applications need only the continuously produced high-temperature one-atmosphere steam and not the pressure because OAB steam exits at a high velocity of up to 4-40m/s. Unlike a boiler, the OAB® or HGA can be turned on and off on demand. Please use SaniZap or HGA-M (steam/air/gas mixture) for product finishing processes with steam. Please consider the HGA-S-01-superheated-steam-generator for oxidation studies or the OAB-4 (from 300C to 1200C).

- Solutions and models range from modern industrial OAB-class models (4-3000+ kg/hr.) to smaller HGA-class models (1 kg/hr. Voltage 120/220V).

- Replace an 80kW conventional boiler with a better-performing 4kW in specific applications with Steam Tunnels. See ROI (Savings).

- Instant On-Demand Steam Generation. InstaBoiler™ TechnologyApplications.

- Patent Protected

- High-quality steam or steam/gas mix, or pure steam, are available if required. Varies by model.

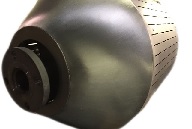

- Standard output nozzles connect to existing standard piping.Standard BPE isE allowed. Delivery tube,s called Vittori tube,s are provided.

- Compact designs are easily adaptable. Very high-flow systems are available for industrial use. Depending on the model, the exit velocity is several m/s.

- From heating to cleaning at several levels. Easy applications.

- High temperature without pressure. Adjust the temperature by power and distance.

- Energy efficiency extends to a myriad of essential steam applications

- Now offering 50 Bar discharge velocity on unique models up to 550C

- Steam temperatures from 100°C to 1300°C. Patent Protected.

- No moisture in OAB® steam. From start-up conditions.

- Assortment of extender pipes and insulation.

- And more….like easy-to-install… thermal fluid heating…easy to operate..multiple streams…modern controls, industry-tested… innovative Videos, and Media Gallery.

What is superheated steam? Steam can be saturated or superheated. When at the boiling temperature (which depends on the pressure), it is called saturated. When above this temperature, it is called superheated. At sea level and one-atmosphere pressure (101KPa), steam boils at 100C (212F), the saturated steam temperature for this pressure. Above this temperature, it will be superheated. Good, high-quality superheated steam is dry steam with no water droplets in it.

New steam from a conventional boiler is rarely 100% dry. In contrast, the OAB steam is 100% dry. In traditional boilers, heat loss causes the steam to condense and become wetter as it travels down the steam line. A decrease in steam dryness hinders heat transfer. Therefore, monitoring steam dryness is essential to provide optimum heating efficiency for your system. OAB steam generators produce dry steam. OAB locations can be close to the user’s device. MHI’s steam devices provide high scalability, reliability, and versatility of pure steam for high and very high temperatures. Such steam can be used for chemical (labeling or food), heating, or general steam use. The OAB® generators provide steam with enhanced energy efficiency with features encompassing no pressure (one atmosphere) to high pressures. Unlike many Boilers, the OAB Steam Generators may be relocated even after the first installation. Very small footprints. In several applications ranging from heating vats, reforming, biomass conversion, antibacterial, packaging, paint and epoxy removal, textiles, regeneration of chemicals and powders, steam oxidation, making the most appealing packaging, and other standard steam uses like textile, bio-pharma, bio-fuels or for testing, the energy savings from OAB® pure steam offers an energy savings of up to 95% and concomitant water savings. Each user is different; Please Request Information for your specific use.

The use of higher-temperature steam leads to energy-efficient applications. This is smart power. Higher temperatures equal higher productivity for most applications of steam.

This Steam Applications page discusses many examples of the benefits of high-temperature steam – smart-superheated steam. Significant growth in the steam market is predicted. Switching to innovative OAB® continuous steam is warranted. Please contact MHI.

Superheated steam carries more enthalpy, or total energy, than air at the same temperature and pressure. For example, air at 1 atmosphere and 300°C has an enthalpy difference of 575 kJ/kg compared to air at STP. Under the same conditions, Superheated steam has an enthalpy difference of 2495 kJ/kg* (numbers are approximate). Thus, superheated steam carries over five times the total energy of air compared to the same initial and final conditions. This gives superheated steam a much larger capacity to do work or perform effectively for chemical (packaging) or food processing needs than other gases. Consider use in Brewing & Distillation, Chemical Processing, Clean Steam & Humidification, Commercial Packaging, Dry Cleaning & Industrial, Laundries, Asphalt Heating & Liquid Terminal Facilities, Food Processing, Gas & Oil Processing, Paper Processing, Pharmaceutical Processing, and Textiles.

Superheated steam carries more enthalpy, or total energy, than air at the same temperature and pressure. For example, air at 1 atmosphere and 300°C has an enthalpy difference of 575 kJ/kg compared to air at STP. Under the same conditions, Superheated steam has an enthalpy difference of 2495 kJ/kg* (numbers are approximate). Thus, superheated steam carries over five times the total energy of air compared to the same initial and final conditions. This gives superheated steam a much larger capacity to do work or perform effectively for chemical (packaging) or food processing needs than other gases. Consider use in Brewing & Distillation, Chemical Processing, Clean Steam & Humidification, Commercial Packaging, Dry Cleaning & Industrial, Laundries, Asphalt Heating & Liquid Terminal Facilities, Food Processing, Gas & Oil Processing, Paper Processing, Pharmaceutical Processing, and Textiles.

Safe high-temperature steam

Unlike a traditional steam boiler system, the high-temperature steam output for the MHI Superheated Steam Generators is at a safe standard atmospheric pressure (room pressure). Compare this feature to boiler systems that must induce high pressure to produce steam at temperatures yet not significantly higher than about 100°C-134°C (1 bar – 3 bar), which is possible with standard boilers/autoclaves. Consider the HGA or OAB for a much safer high-temperature steam solution.

Please note that the steam is still very hot and requires all the safety precautions similar to or exceeding those for hot gas handling.

How do Temperature and Pressure Impact a Steam Reaction? OAB® Compared to Traditional Boilers.

Learn more about OAB® and its applications

How do Temperature and Pressure Impact a Steam Reaction?

OAB® Compared to Traditional Boilers

Steam Calculator, Productivity Enhancement and FAQs |Physical Properties of Moist Air/Gas | What are Steam and Humidity?

Productivity Enhancement and FAQs

Physical Properties of Moist Air/Gas

How do Temperature and Pressure Impact a Steam Reaction? OAB® Compared to Traditional Boilers.

Learn more about OAB® and its applications

How do Temperature and Pressure Impact a Steam Reaction?

OAB® Compared to Traditional Boilers

Steam Calculator, Productivity Enhancement and FAQs |Physical Properties of Moist Air/Gas | What are Steam and Humidity?

Productivity Enhancement and FAQs

Physical Properties of Moist Air/Gas

High-Efficiency Steam Recirculating Ovens

————–Steam Cleaner————————

Want to find out how MHI can help you meet your steam needs?

Please fill out a quick questionnaire by clicking on the product of interest.

We will help find a good solution to meet your needs.