Airtorch® Home Page

Click for typical applications

Energy Savings with an MHI Airtorch®.

Airtorch® Selection Table

| Temperature | Lower Power (1-12 kW) | High Power (30 KW- MW) |

| 600-950°C | LTA, VTA, MTA925 | MVTA-900-(THN/DNA/DH) Models |

| 900-1100°C | (Custom), DNA, SH | MVTA |

| 1000-1200°C | DNA, SH, DPF Models | (Custom) |

| High-Pressure Enclosures | SH, DPF |

Is the Airtorch® Energy Efficient? Yes.

Are Airtorch® correct rectors for simultaneous chemical-induced reactions? Yes, with MHI technology.

*Contact MHI to determine if you need to plan for any extra power to compensate for losses

For the Airtorch® model chosen, please multiply the SCFM/kW from the graph with the kW of the selected model for the desired flow*.

Clean – Decarbonize

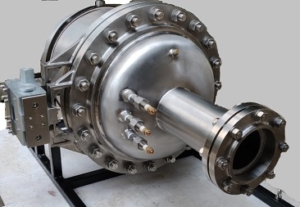

MHI Airtorch units are constructed with safety to touch outside shells.

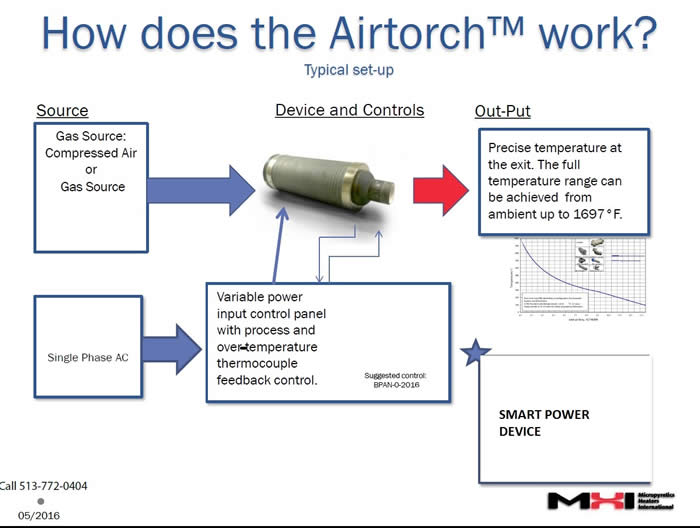

The Airtorch® is a high-temperature forced air convection system that employs a particular class of elements (appropriately chosen for a gas to be heated) to heat the ambient air/gas or the heated air towards a surface (or coatings) or into a chamber. The Airtorch® is constructed with a combination of ceramics, nano-intermetallics, and metals – particular material combinations for the system to perform with the highest power-conversion efficiency for the gas heated. Depending on the model, the Airtorch® system can achieve temperatures up to 1200°C (~2192°F) with infinitely variable volume flow rates, adjustable temperature and power, no noise, low-pressure drops, and no harmful emissions (zero fossil fuel use), thus providing a beneficial new heating method with modern controls. MHI Airtorch® applications are seen in drying, electrical varnish, process gas heating such as hydrogen gas, coatings, powder spray heating, weld preheating, die heating, rubber roller die heating, plastic softening before forming, drying motor parts, removing moisture, expansion fitting, preheating and heating molds, curing, prosthetics, heat shrinking, compression molding, flock setting, curing catalysts drying slurries, deep-decarbonization, freeze drying, improving ink print finish, finishing mirror drying, latex, heating adhesives, and general heating of gases and furnace chambers as discussed below with the schematics

Heated air or process-gas. Return on Capital.

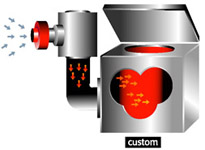

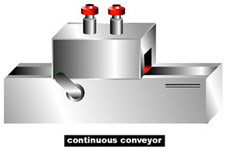

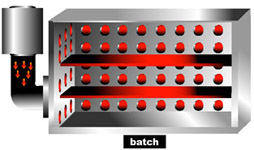

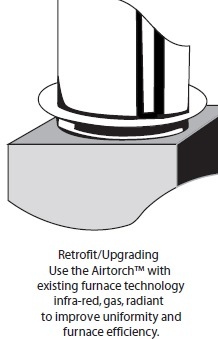

Augmentation Use for improved uniformity and additional power: Add an Airtorch® to an existing or new chamber for powder, liquid finishing, and general process augmentation. Add to continuous furnaces for wood conditioning, metal finishing, and forming. The Return on Investment (ROI) from an Airtorch® installation is usually very high. The Airtorch® models often qualify for the MHI-Never-Down program. Several Airtorch® models are available. The three broad application scenarios are diagrammatically captured below.

Please use the 5-step selection process. First, choose the maximum rated exit temperature of the Airtorch. If below 900°C, please choose TA or SH, e.g., VTA and MTA models. If above 925°C, please select the SH/DNA, MVTA, or DPF models.

The Airtorch® convective system uses a particular class of elements to heat the ambient air and direct that heated air towards a surface or into a chamber. Depending on the model, the Airtorch® system can achieve temperatures ranging from room temperature to 1100-1200°C (~2200°F) with infinitely variable volume flow rates and no harmful emissions, providing a beneficial new heating method with modern controls.

Energy Savings with an MHI Airtorch®.

MHI Airtorch® applications are in drying electrical varnish, weld preheating, die heating, plastic softening before forming, drying motor parts, removing moisture, expansion fitting, combustion, simulation preheating and heating molds, curing, prosthetics, heat shrinking, compression molding, flock setting, curing catalysts drying slurries, freeze drying, improving ink print finish, finishing mirror drying, latex, heating adhesives, and general heating of chambers as shown below. Add to compartments for powder and liquid finishing. Add to continuous furnaces for wood conditioning, metal finishing, and forming. A tiny but finite temperature drop is experienced when directing Airtorch® flow with insulated piping because of the high velocity.

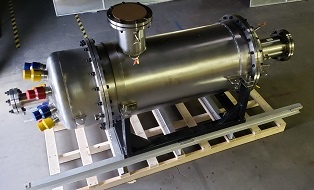

- Megawatt compact Airtorch systems are used for hydrogen heating, air drying, replacing combustor ovens with electric ovens, and other special applications.

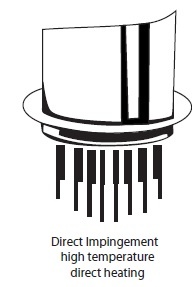

- For impingement types of applications, the DPFs offer very superior value.

- A good rule of thumb for augmenting uniformity in an existing furnace with an Airtorch™ add-on is to choose an Aitorch power with at least 30% of the original (unless it was already a gas-heated oven). This may not be enough if a temperature increase is also sought.

- When planning to extend the Airtorch exit piping, please note that well-insulated pipes will drop the temperature very little as the exit velocity is m/s. A helpful but rough rule of thumb may be about 50°C-100°C/m drop for good internal pipe insulation. Good pipe insulation is specific to whether the pipe is internally or externally insulated. The MHI industry standard is about a 1-2″ thick insulation. Please contact MHI when required.

The use of Airtorches™ with Air as the heating gas may be classified into three major categories schematically drawn below.

Introduction to Airtorch™ | Airtorch™ Applications | Calculating Power vs. Flow Rate | Easy Design Criterion

To convert a natural gas heater oven, combustor, or chamber to an air-heated one, the following questions should be answered. Generally, electrical heating efficiencies will be better, and because the exhaust is just hot air, one can use it for room heating or other purposes or recycle it.

- The chamber size

- Chamber temperature 200C, 400C, 700C, 900C, 1000C, 1200C.

- Current exit gas temperature?

- The number of burners and number of inlets and exits

- The current natural gas burn rate/power. This will be on the KW or Btu/hr burner multiplied by the number of burners.

- Whether using any heat exchangers currently – in case recirculating air is beneficial.

- Supply (voltage ) available at the company.

Direct Impingement |  Airtorch Inline Use as Recirculator Recuparator Save Energy |  Retrofit for Enhancement |

Direct Impingement.

High temperature direct die heating, surface ignition, surface processing, chemical processing, additive manufacturing

Airtorch

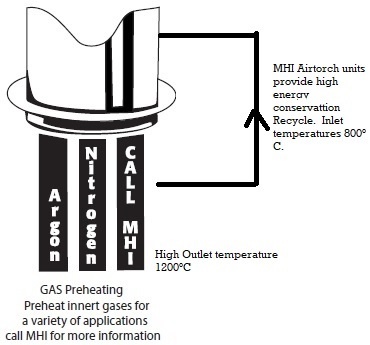

Gas Preheating.

Preheat inert gases for a variety of applications.

In Line Use

Use the Airtorch® for Inline Use

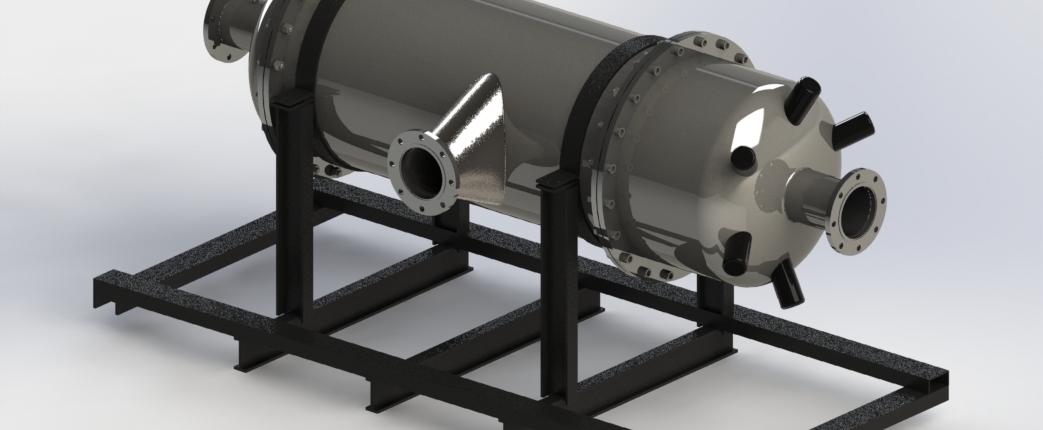

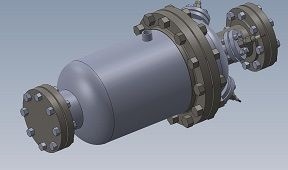

- Large Flow MVTA. For 1000-1200°C. These are sealed process gas heater (THN or DNA class) with blower or inline capability. High KW – High Flow.

- Large Flow GTA – For high pressure vessel Airtorch® use. Custom engineering. Please contact us directly for assistance.

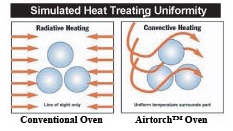

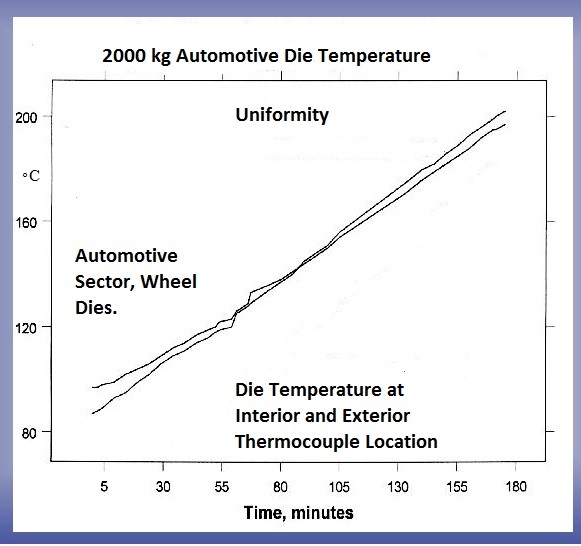

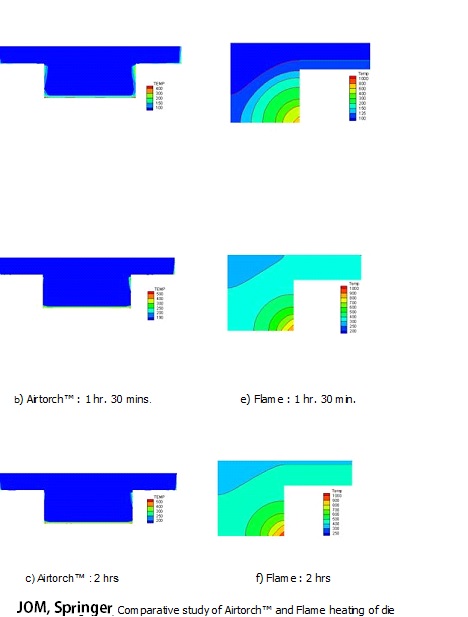

Heating with Electrically heated Air provides Uniformity Compared to Flame Heating

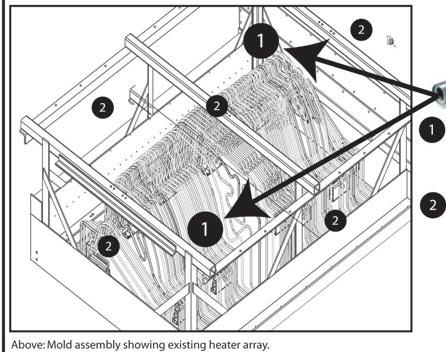

Example of Use to Augment an Existing Furnace Installations for Improved Power and Uniformity. An example of a 4kW Airtorch™ augmentation application is schematically shown below. In this application, many complex-shaped rods are to be heated uniformly. The heat-treater reported that the rods were not uniformly heated in his existing radiant heat furnace. MHI proposed an add-on to his existing furnace with a system of Airtorch which then significantly impacted the uniformity and reduced the total energy consumed. More Green Installation and more Profits to the user. Improve oven performances and eliminate harmful emissions.

As a rule of thumb, an Airtorch power of 0.3 the furnace power is employed when designing for better uniformity. | |||

Heating: Create a convective cavity around the assembly using two 4kW Airtorch™ units. Fixture Airtorches™ behind mold and electrodes at angles to create air movement. This should improve the overall heating of the mold. Insulation: The assembly is surrounded by refractory blankets (all five sides) to retain as much heat as possible. MHI can supply blankets at the customer’s request. Solution: By supplementing the existing electrodes with the Airtorch™ and blankets, the watt density is increased on the mold, thus reducing the workload of the current electrodes, which should improve performance and life. Other results include an increase in uniformity across the mold surface. Call MHI for more information. |  | ||

| |||

| |||