MHI Airtorch® Design Graphs

For flow calculations, please contact MHI.

Energy Savings with MHI Airtorch®.

From 2 KW to 16 MW, 30MW, or even 100MW.

Energy and Environment Improvement with an MHI Airtorch®. Click here.

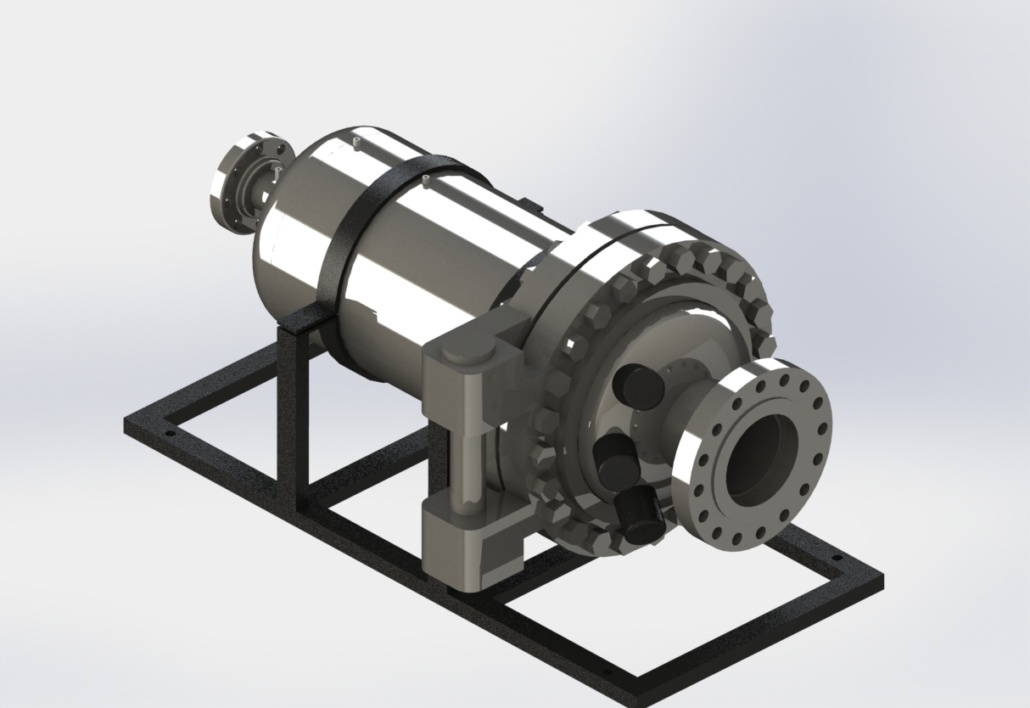

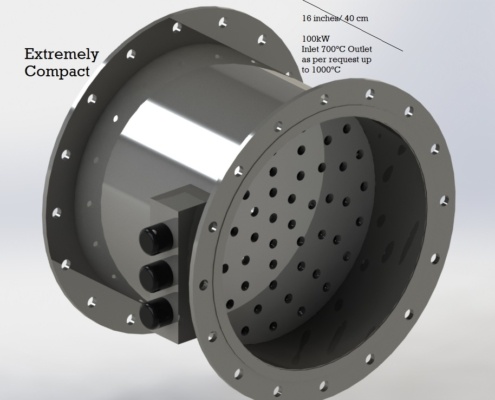

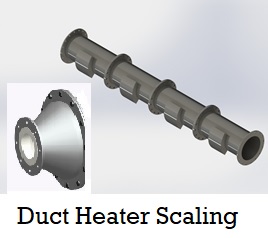

The Airtorch® may also be used in a recuperative mode. MHI can provide an Airtorch® unit with an input temperature of more than 700°C and an output temperature of up to 1200°C, making the MHI DH add-on an ideal component for all large ovens.

Why do hundreds of customers prefer MHI for their best energy-efficient air heating needs? Now, we are offering new and improved heating elements with an incredible warranty. Please Contact MHI.

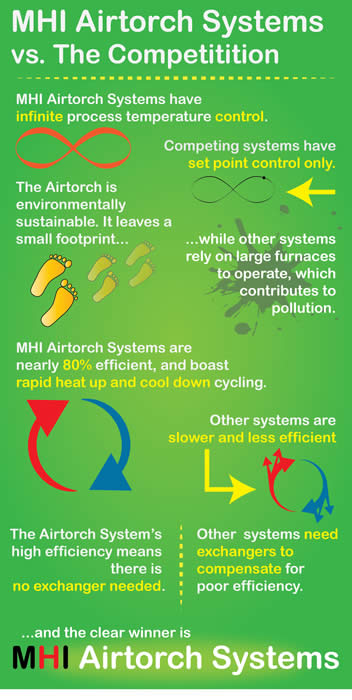

When comparing Airtorch® against heat exchangers, please note that the MHI Airtorch® units often save considerable energy because of their low-pressure drops. This power loss could be substantial with heat exchangers. For example, if a flow of 0.6 kg/s is driven with a 5 Bar (~90 psi) pressure, then almost ~200 kW of power could be wasted for driving the flow compared to the Airtorch® systems that offer an extremely low-pressure drop (~ 1 PSIG). Or 2000KW if the ultra-low pressure drop Airtorch® models are used for 0.1 psig.

Please review the properties of gases and formulas to use for power calculations.

MHI Airtorch products offer a very low-pressure-drop (low loss).

- 1kW Savings per year is $876 @10c per kWh

- 10kW Savings per year is $8760 @10c per kWh

- 100kW Savings per year is $87600 @10c per kWh

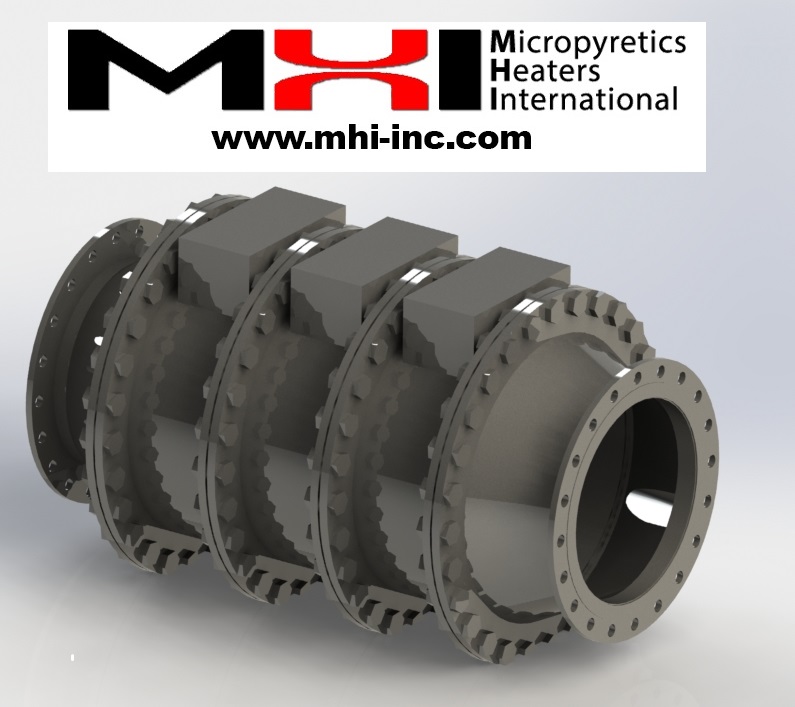

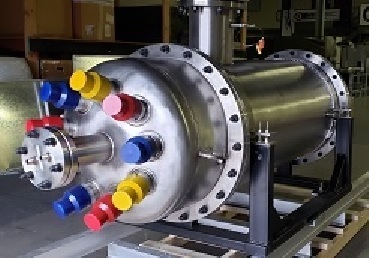

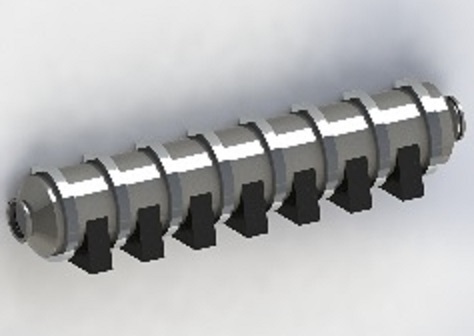

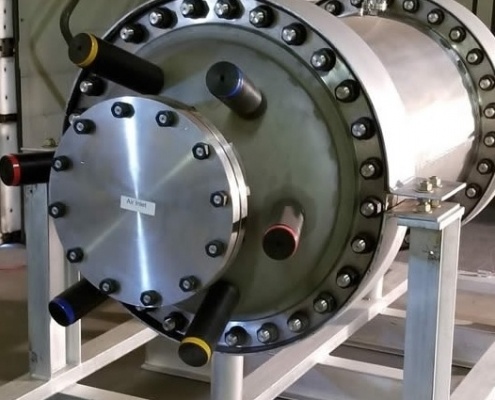

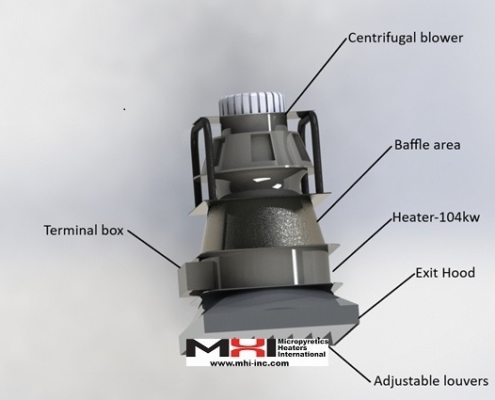

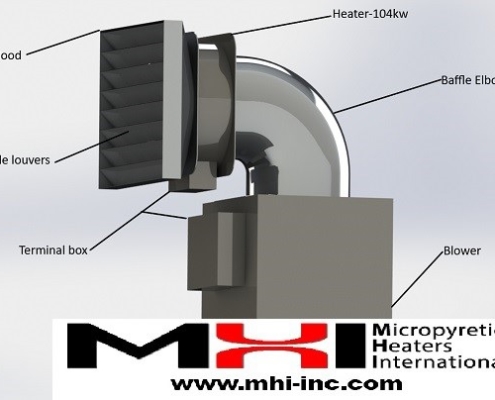

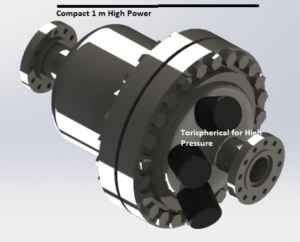

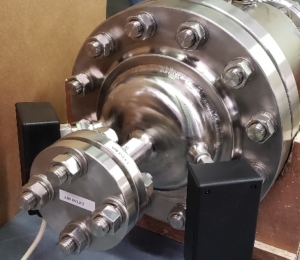

Large Flow MVTA. For 1000-1100°C. These are sealed process gas heaters (THN or DNA class) with a blower or inline capability—high KW – High Flow.

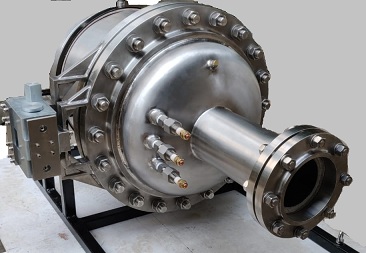

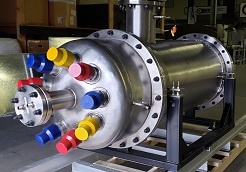

Large Flow GTA – For high-pressure vessel Airtorch use. Custom engineering. Please contact us directly for assistance.

Typical Conversion of Gas

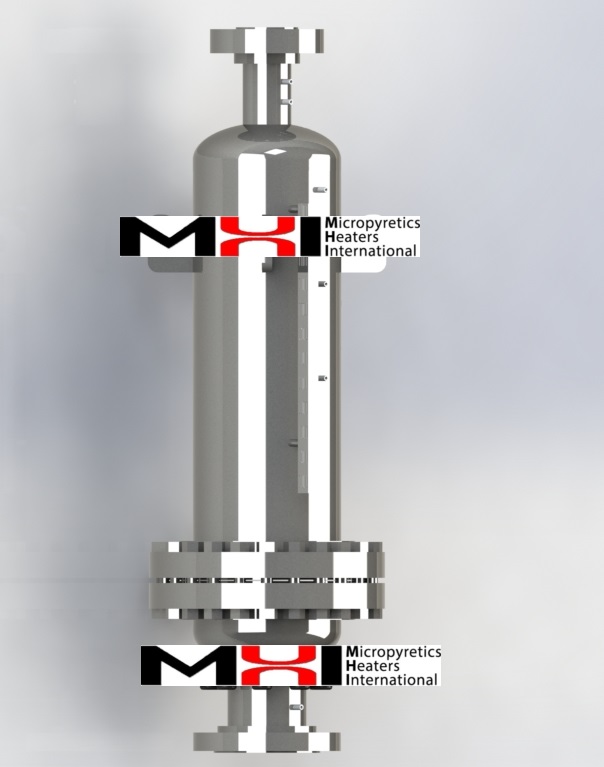

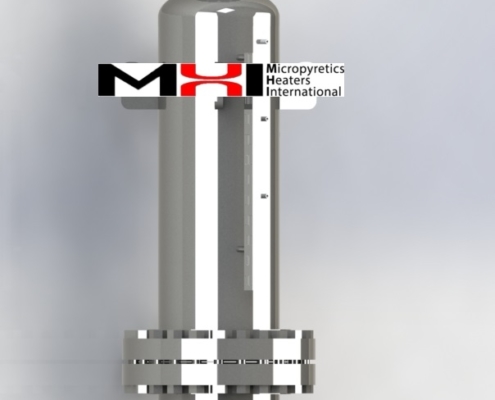

LTA – Up to 900°C. LTA is a process heater for air that requires a compressed air input.

VTA—Up to 900°C. A VTA is a process gas heater with a fan or blower and low-flow sensor capability.

MTA925 and GTA – Up to 925°C/1100°C. These are flow or inline-sealed process gas heaters that can take compressed air or compressed gas input—new Models for the MVTA-DPF-DNA Class.

DPF – Up to 1150°C-1250°C/~2200°F. DPF models can take fan or blower input and a compressed air/gas input.

| N2 gas | Weight | Gas | ||

| pounds (lb) | kilograms (kg) | cubic feet (SCF) | cu meters (Nm3) | |

| 1 pound | 1.0 | 0.4536 | 12.83 | 0.36 |

| 1 kilogram | 2.205 | 1.0 | 28.24 | 0.8 |

| 1 SCF gas | 0.07245 | 0.03286 | 1.0 | 0.02832 |

| 1 Nm3 gas | 2.757 | 1.2506 | 35.3 | 1.0 |

| SCF (Standard cubic foot) gas is measured at 1 atmosphere and 70°F. Nm3 (Normal cubic meter) gas was measured at 1 atmosphere and 0°C. |

Quick conversion mm H2O column difference to psi:

1 mm H2O column difference to psi = 0.00142 psi

50 mm H2O column difference to psi = 0.07112 psi

100 mm H2O column difference to psi = 0.14223 psi

Quick Conversion of bar to kPA

| bar | kPa |

| 1 | 100 |

| 1.2 | 120 |

| 1.4 | 140 |

| 2.0 | 200 |

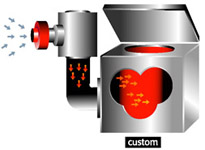

Airtorch® Mode. Heat from cold gas to hot gas quickly.

Airtorch® Recuperator Mode. SH models accept inlets up to 300°C and under special conditions to 600C.

Example-Air. Use the blue-black line for a steady state and cold start.

Use the purple line only in recuperator mode.

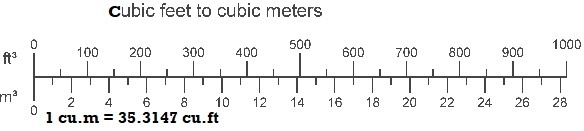

Conversions:

Actual: 1 m³= 35.31467 ft³

Hagen-Poiseuille equation: ΔP = 8μQL / πR^4 ( MHI Airtorch models offer low friction)

_________________________________________

Standard value (approximate Conversion)

1 Nm³/h is ~ 0.59 SCFM

Or

1 SCFM ~1.6 Nm³/hr.

_________________________________________

Power

1 MBH = 0.293 kW

Psst: An approximate way to theoretically calculate is SCFM = KW x 3193/∆T where ∆T is in °F. Use his method (and a little margin) for temperatures below 1200°F. For higher than 1200°F, Contact MHI.

Ideation

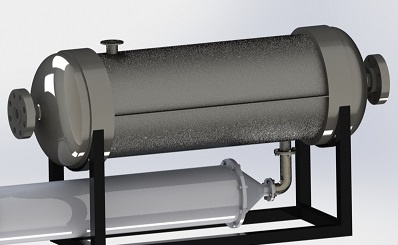

Tori-spherical

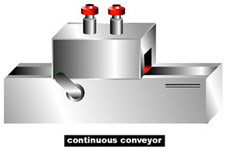

Continuous Overn with Airtorch