Impart rapid water repellance. Glass bending, smoothening, shaping. Case studies for optical data transfer glass. Better user experience because of smoothness and water resistance.

Bring your intelligent designs to life with creative shapes made with the Cascade e-ion rapid glass bending technology. Surface harden optical data transfer glass with superionic rapid nitrogen impingement with just air input.

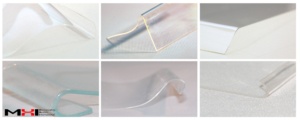

The Eion glass treatment for tempering or bending and tempering has been noted to improve uniformity and reflectiveness for data glass and HUD glass when bent. Bending to most curvatures—small and deep—is easy. The patented beam technology enhances the productivity of bent glass, sometimes with ancillary enhancements. Proper substrate materials (often proprietary) significantly reduce asperities or ripples, a feature required in HUD glass. All glasses are different – we recommend that users develop their process with our minor guidance.

Protective glass used in electronic displays is surface treated and/or bent for reasons that involve design as well as information selection and transfer abilities. Elegant curvatures and variations in surface properties can be used to distribute information creatively in electronic displays. The casc de e-ion brings new versatility and opportunities to glass processing.

Glass bending requires a glass (disordered internal structure) to be heated above a temperature (e.g., glass transition) and deform into the shape required with the correct apparatus and wavelengths. Shaping is an art. Exact conditions for shaping vary from glass to glass, with changes in the composition and details of the internal atomic disorder. Glass is bent for decorative reasons and to alter the direction of the information display. The casc de e-Ion uses super ionic pressure that can be used to deform the glass without cracking. Simultaneously, often, the scratch resistance and smoothening are enhanced. Have you glass tested?

Bend cell phone glass, wrist-information watch glass, GPS glass, HUD glass, electronic glass, smartphones, sapphire equivalents, touch screen glass, tablet glass, and so much more at rapid production rates. Bring your intelligent designs to life with creative glass-shaping offered by the Cascade e-Ion with super-hard surfaces if desired. Change the surface characteristics and heat resistance at a meager operational cost.

Bend and smoothen the glass surface with the slot aperture Cascade S-e-Ion in the plume mode with the air plume shown below.

What to buy from MHI: The Cascade S-e-14 and the particular substrate are machined to your curvature/dimensions.

Create beauty, differentiate your product, change brightness/contrast, and creatively distribute or capture helpful information. Multi-angle displays and curved glass – please let your imagination consider complex glass cover shapes with the Cascade e-Ion machines. Experience simultaneous ionic hardening? When you purchase a cascade machine, you are freely enrolled in the expanding group knowledge and the Never Down system. Use for curved glass or syringes. Please do not hesitate to request a sample ROI.

Decarbonized glass bending and shaping. Sometimes, a 400kW glass bending machine can be eliminated by a 4 kW plume glass bending. Only electrical and air inputs are commonly used. The plume is an air plume.

The surface properties of many super ionically bent/shaped glasses were found to be much more scratch-resistant. This is a critical requirement in optical data transfer glass and laminates.

The Cascade e-Ion technique can rapidly shape for production – bend in less than a minute – because of the unique ionic beam that protects the glass while bending and distributing heat evenly. Considerable variations in creative bends may be achieved. Ev n the hook and multi-axis bend, including convex and concave, as shown for the illustrative hat-curvatures above, are possible – please contact MHI for information. Unique complex shapes for advanced electronic display glass (for all types, including aluminosilicate glass) are shown below. Many other shapes are not shown because the user has requested that we not disclose them until they have entered the market with their shape. T Cascade e-ion machines/models do the perfect job. MH provides Jigs as appropriate for a nominal price.

MHI delivers the capability to design. Super ionic bending.

The picture shows deep and wide ionic-plume-curtain for rapid treatment, including edge-bending of glass/sapphire glass. The picture displays an air plume at one-atmosphere conditions of ionization. The cascade ion treatment enables a significant water-resistant property measured by the water contact angle. Need more information? Contact us

Use the Cascade e-Ion Plasma™ to bend, treat, or shape glass! It produces clean and quick results, Is Energy-Efficient, and offers ionic modification possibilities for wear resistance and smoothness.

“Smart Glass Bending”

The Cascade e-Ion Plasma™ (a Patented MHI product) can be used to bend glass, i.e., the ions can be used to manipulate glass bending. The Cascade e-ion Plasma operates at about 1-15 kW. In contrast, certain soda-lime-silicate glass types are often bent by heating in very energy-inefficient furnaces (almost 50kW), i.e., if at all bendable from flat shapes. Do you wish to bend quartz or sapphire glass three-dimensionally from glass? Single-operation surface ionic operations and tempering are often feasible with the Cascade e-ion machine benefactors. 4D sintering is a registered trademark of MHI.

Bending is easy with the Cascade e-ion technology. Enhance the surface while bending.

For example, MHI is working on uniquely exciting ion-hardening techniques that use the beam’s ionic nature to successfully modify several glass and sapphire substrates. Purchasing a patented Cascade e-ion machine enrolls you into the select group. We know you will enjoy the new ideas from you and others.

Electronic Display Glass for Optical Data Transfer

Display Glass is an alkali-aluminosilicate toughened sheet glass. Such types of cover glass combine thinness, lightness, and damage resistance. It is used primarily as the cover glass for portable electronic devices, including mobile phones, portable media players, medical information displays, portable computer displays, HUD, Needle Syringes, and some television screens.1

MHI Cascade e-Ion Plasma™ allows rapid bending of flat glass. The photographs show electronic glass smoothly bent within a few seconds in the CleanElectricPlume™. Please call us @ 513.772.0404 or contact us for more information about this innovative technology. Many shapes are possible, such as decorative dimpled surfaces, origami shapes, hierarchical crystals, and folded napkin shapes.

These shapes can be produced by simply applying the correct bend points with the cascade e-ion machine, as shown below for curved surfaces. All shapes can be made rapidly and energy-efficiently while not losing any significant properties of the glass. Regardless, specific testing on your glass is recommended and is often free.

Please contact MHI to acquire a glass bending machine suitable for your design.

Shapes are normally made within a minute from flat plate condition – fully automatable with continuous belts and appropriate robots. Ot er materials handling systems may be incorporated. The Cascade e-Ion System particularly empowers design creativity.

The picture below shows the axis points for the curvature’s origin. These are edge reflections of a bent glass. The Cascade e-ion Plasma and special MHI jigs enhance such creative bending. Note that the Cascade e-ion offers many different types of apertures.

![]()

Is Glass a Solid? Ask MHI.

Answer: Glass below its glass transition temperature is a solid in that it has a very high viscosity and, therefore, is very rigid (does not shear easily). Crystalline and amorphous ceramics can be transparent in the visible range. The common form of glass is a transparent amorphous solid. Glass has several applications, such as windows, electronic displays, and transparent armor and coatings. Several glass compositions exist. Some common ones are borosilicate glass, normal glass (i.e., plate-glass soda-lime-silica), and other combinations of fused silica glass. Other considerations play a role in selecting when shaped glass is required. Here, the cascade e-ion has a particular advantage for rapid volume production. Chemical, Ionic, or Thermal treatments can increase the strength of glasses. The Cascade e-ion is versatile.

The controlled crystallization of specific glass compositions is also employed to manufacture optical-quality glass ceramics. With the cascade e-ion, several active gas and ionic covers can be contemplated, even considering SiAl-oxynitrides, known as SAILONS. Other new materials may be contemplated.

In a sense, the Cascade e-Ion has made the future a bit brighter.

Do you wish to edge bend, surface harden, smoothen, and make water resistant a layered or laminated glass? Please consider whether a cascade e-ion model may fit your requirements.

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA