Steam Testing Chambers

Useful for steam oxidation, testing steam reactions in the laboratory, testing for environmental innovation, and food or antimicrobial testing purposes

Depending on the model, the chambers may be used for steam up from a low-temperature 1300C. Independent control of steam, gas, and chamber with industry-tested control panels.

There are two standard models. Contact for standard models to 300°C and 1300°C for testing, for example, bacterial inactivation in food or for testing for long times in continuously replenished fresh steam conditions.

Accurate sample positioning and multiple temperature readouts are offered.

Please contact MHI for details to specify the steam flow rate, temperature, sample size, and temperature.

These are one of the best test chambers as they allow continuous-flowing clean steam to provide steady-state test conditions with time-independent steam gas.

The smallest chamber size is 1″ID, and a 4″ Long, open chamber.

HGA Based Chamber Design.

Steam Output: 1 kg/hr.

HGA Models: Pure Steam.

Temperature Range:

300°C (HGA-S-01) to

1300°C (HGA-CX1300)

Model S-Chamber -01-300 1Kg/hr 300C steam

Model S-chamber -01-1300 1Kg/hr 1300C steam

Steam Rate Flow Adjustment: Discrete and continuous mode is available

Test in chamber with premixed steam air mixtures with HGA-M.

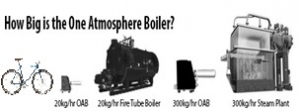

OAB Based Chamber Design

Steam output: 4-12 kg/hr. OAB® Models

Models (4kg/hr or 12kg/hr)

Single phase 208-240V, 50/60 Hz.

Model S-Chamber-04-300 4Kg/hr 300C steam

Model S-Chamber-04-1200 4Kg/hr 1200C steam

Temperature Range: 300-1200°C

Steam Rate Flow Adjustment: Discrete and continuous modes for steam flow adjustments.

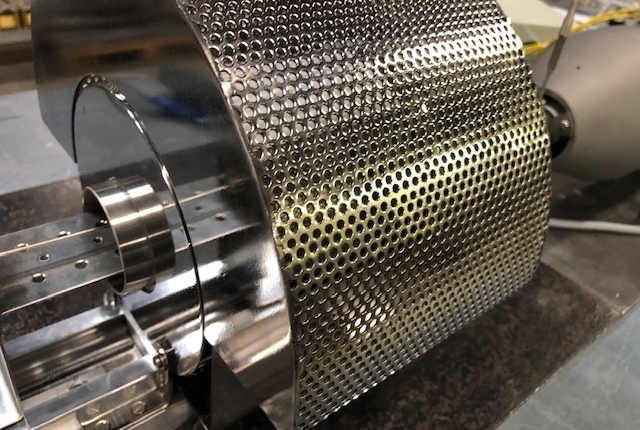

Steam chamber seals and steam rate valve

Want to find out how MHI can help you meet your steam needs?

Please fill out a quick questionnaire by clicking on the product of interest.

We will help find a good solution to meet your needs.

FAQs for Steam Chambers

(Based on questions from previous sales).

(a) Are there recommended minimum & maximum coupon sizes for superheated sample testing? The chamber is 1.5-inch in diameter & 4-inch in length.

(b) Can gas be introduced?

Yes. with the gas port attachment.

(c) What is the total distance (upper and lower) between the coupon and the steam applicator? Can I vary the steam rate? Yes, with a CN-BPE or BPE. The CN-BPE, if offered for the model, offers continuous adjustment from 0.3Kg/hr to 1 Kg/hr.

(d) Are there any constraints in varying coupon exposure time to superheated steam? (e.g., minimum exposure time & max exposure time)?

No

(e) Are the coupon (or) steam applicators both fixed? In other words, can this be done if we need to vary the rate? (it may be related to question c).

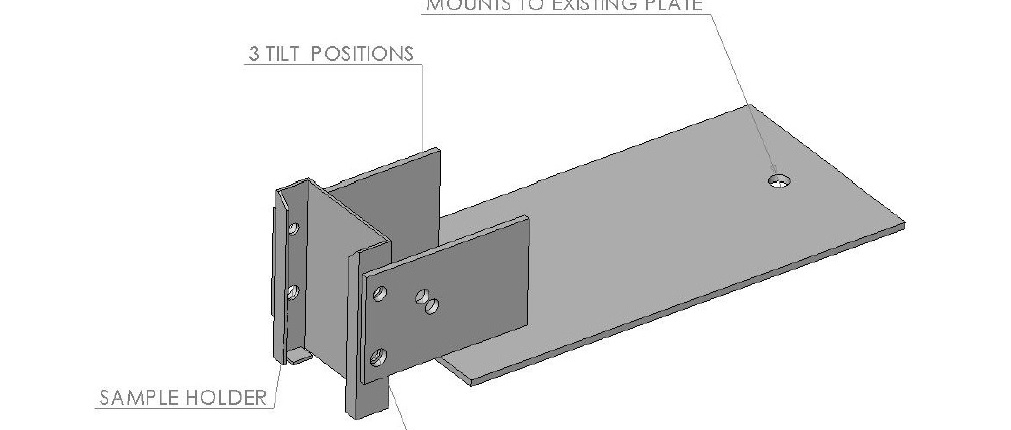

Sample Holder is Multi-axis # Tilt Positions

Fixed, or you can continuously change.

(f) presume we can monitor humidity within the chamber with an appropriate probe sensor during the experiments

Please see https://mhi-inc.com/PG2/steam-superheated-humidity-generator.html. Humidity is not defined for high-temperature steam.

(g) What are the upper and lower temperature limits for steam? At what increment can temperature be controlled?

Up to ~400C or 1000C, or 1300C. Infinite control is allowed by MHI control systems.

(h) can the steam velocity be varied?

Not without changing nozzles. A ¼” nozzle is provided. Note that the volume flow rate is fixed.

(i) Are there any constraints with a water source (e.g., DI water or tap water is OK?)

RO water is preferred.

(j) Do you offer a Data Acquisition system?

The models are supplied with an interface for data acquisition.

(k) What if I want a moving product steam tunnel

Please link to steam tunnels.