Agriculture microbial and fungus treatment with Steam and Steam Medium

HGA-M Superheated Steam/Air Mixture Generator

Using steam/air to dry

Using steam/air for antibacterial and antimicrobial treatment

HGA-M

Model(Click on the model number for price and specifications.) | Output | Power | Voltage |

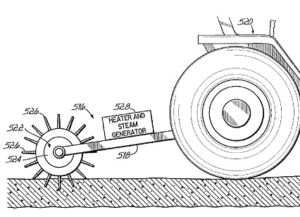

HGA-M-01 (in web store)or HGA-M-04 (in the web store)or SaniZap-1 for Commercial Cleaning and Sanitizing___________________________HGA-M-04Use for heating air or gas and mixing with steam.Total power: 4 KW.____________________________________ Steam Gas mixture for up to 8KW and aboveGOAB-M Models

____________________________ | Superheated SteamandMixtures as per Model | _____ HGA-M-01 _  Air Steam Mixture Generator ___________________________ | 110V 50/60Hz ——————————– |

SaniZap-4 for Commercial Cleaning and Sanitizing

Typical Specifications for HGA-M (patented)

Contact MHI for all types of steam products

HGA-M is an Air/Steam generator product

Typical settings for 1 KW (multiply by 4 for the 4 KW):

(Full power of 1 kW): Air 1.45 CFM (inlet at ~30C) and water 330ml in 45 mins (inlet ~30C) yield steam-air temperature of about 350°C. Air 1.4CFM (inlet at ~30C) and water 200ml in 20 mins (inlet at ~30C) yield a steam-air temperature of about 250°C. Air 1.8CFM (inlet at ~30C) and water 200ml in 20 mins (inlet at ~30C) yield a steam-air temperature of about 150°C. The values above should be considered approximate. Your results may vary with the Unit and the type of use. The Unit has a manual with comprehensive valve setting data (manual available only with purchase). HGA-M use requires the purchase of a flow meter and a compressed air source.

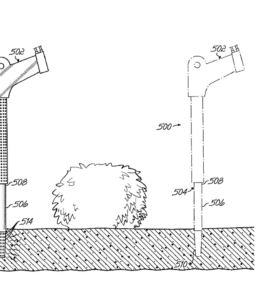

High-temperature humidifiers can be used for the antibacterial circulation of air/steam.

Article on HGA output for steam and superheated steam.HGA-S-01 (pure steam), HGA-M-01 (steam-air or gas mixture) Read an article on "Drying with steam or drying with air - a case study for clay, wood, food processing, etc".

A rack of HGA-M’s, SaniZap-1, or SaniZa-4 may be used, or a larger unit can be quickly developed. Contact MHI.

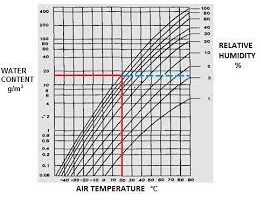

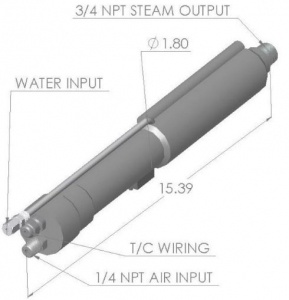

High-temperature superheated steam-air or steam-gas output. Superheated steam is an odorless, high-temperature gas (not to be confused with hot water mist). Several options are available and recommended. Voltage: 110VAC for 1 KW, 240 V for 4 KW. Frequency: 50/60 Hz Current: Approx. 9 Amps @ 110VAC for 1 KW, ~36 Amps@ 240VAC for 4 KW. Power Consumption: ~1000 Watts or 4000 watts, depending on the model. Potential uses: Superheated steam is required at one atmospheric pressure for drying, antimicrobial, oxidative tests, fuel production (syngas), cleaning, layering, epoxy drying, and other film uses. It is ideal for steam drying or steam oxidation. The product uses surface, cleaning, drying, and curing technologies, including seeds, food, and nanotechnologies. Attempt use also for precipitating crystals of several small sizes, including nano-crystals from solutions. Precipitation droplet sizes may be controlled by controlling the cooling rate, impingement conditions, and surface type. High Humidity Control: Steam temperature and the relative mass of moisture in the steam-air mixture (specific humidity) depend on the water valve setting and air inflow setting. This unique device can give more than 40% specific humidity at temperatures greater than 100°C(compared with a specific humidity of less than 3% in fully saturated air at room temperature, i.e., air with RH=100%). Typical settings for 1 KW multiplied by 4 for 4 KW: (Full power of 1 kW): Air 1.45 CFM (inlet at ~30C) and water 330ml in 45 mins (inlet ~30C) yield steam-air temperature of about 350°C. Air 1.4CFM (inlet at ~30C) and water 200ml in 20 mins (inlet at ~30C) yield a steam-air temperature of about 250°C. Air 1.8CFM (inlet at ~30C) and water 200ml in 20 mins (inlet at ~30C) yield a steam-air temperature of about 150°C. The values above should be considered approximate. Your results may vary with the Unit and the type of use. The Unit has a manual with comprehensive valve setting data (manual available only with purchase). Safety precautions must be taken when dealing with hot gases. The stand option is highly recommended. The stand option comes with a thermocouple that the user can position to measure the steam temperature at a location of choice. Please write MHI for superheated steam information or refer to any standard book on steam thermodynamics. Safety: DO NOT USE WITH COMBUSTIBLE LIQUIDS. THE DANGER OF SUPERHEATED STEAM SHOULD BE WELL UNDERSTOOD. PLEASE WEAR GLOVES, GLASSES, AND A HARD HAT. PROTECTIVE CLOTHING IS REQUIRED. STEAM CAN PENETRATE CLOTHES. Patents applied and pending. Installation: Installation and use manual provided with the product. Options: A control thermocouple for the hot air generator part is included. Steam output temperature thermocouples and brackets are sold separately, or users may provide their own. An electrical 110-120V i0/60Hz supply is required for this Unit. Both 1 KW and 4 KW system requires compressed air inputs. MHI can offer compressed air units for each. FAQ’s |

| Q: Is steam drying energy efficient? Is it better? A: The answer is YES in many applications. Above the inversion temperature, steam drying is much faster than air drying. Compared to boiling water to remove debris, superheated steam above the inversion temperature of ~200°C is faster and may not require the subsequent drying operation, thus saving you time and money. There is also the possibility that because of the significant enthalpy content and higher than 100°C steam temperature, the cleaning could be more efficient, reach tough-to-clean regions, and eliminate more debris. Q: When do you dry with steam instead of hot air? A: Above the inversion temperature of ~200°C, drying with steam is fast r. There are many benefits to using steam, but the main one is the availability of a gas with a lot of stored enthalpy at a lower temperature than corresponding dry air with the same enthalpy. So if you were interested in drying paper with an ignition temperature of, say, 450°F, then using superheated steam at a much lower temperature may produce the same drying efficiency as hot air at a high temperature, which could be more than the paper ignition temperature. |

For the 1 KW unit, the approximate height is 12″ (~30 c ). Unit is approximately 15.5″ long (40 cm).

Request For Quote

Click here for High-Efficiency Steam Recirculating Ovens.

Patents granted and pending.

For humidifiers below 100°C, don’t hesitate to contact MHI.