Cascade e-Ion Plasma™ Source - Thermal Plasma Generator

(Winner of R&D Best 100 Products Award)

AboutCascade e-Ion Devices

The Cascade e-Ion Plasma™ Source produces a plume containing ions, electrons, radiation and hot gas. It is a versatile tool with many possible applications, especially in implementations requiring minimization of the heat affected zone. Its rapid heat-up time also makes e-Ion Plasma™ powered devices great for general heat treating, RTP replacements, photonic applications and dozens of other highly specialized applications. e-Ion Plasma is preferrable to chemicals for mitigating dross in an aluminum melting process.

The Cascade e-Ion's Wide Area Plasma technology allows for use as an energy efficient plasma covering of nitrogen.

Contact Us for a Live Demonstration

Not sure if the Cascade e-Ion Plasma™ is right for your application? Arrange to have your part treated even during a live video chat.

|

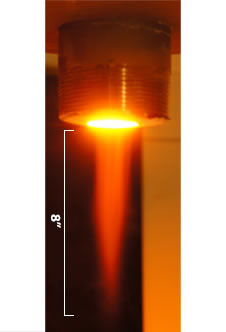

Standard Cascade e-Ion Plasma™ Beam for Brazing and Hardfacing |

Cascade e-Ion Plasma™ Source Applications

Direct Impingement Applications

The LIP may be used for plastics and polymers.

Cascade e-Ion Plasma™ Source Models and Specifications

Please contact MHI for specifications on Jigs, Holders, Material Transport systems like belts or robots. These are custom specified for indicidual applications.

| Cascade e-Ion Plasma™ Source |

| Up to 200K/s Heat-up Rate |

10-15 kW Power Consumption (Depending on Configuration) foe e-10 and e-14 machines S-e_ion is about 16 kW |

| Highly Modular |

| Compact Table Top Sized |

| Highly Accurate Controls |

| No Water Cooling Required |

| Ability to Treat Ungrounded Metals |

| Stainless Steel Construction, Integrated Fan |

| No Toxic Emissions or Combustion Residues |

| 220/230/240 Input Voltages |

| Single Phase or 3 Phase |

| Near Silent Operation |

| Plume Properties Recombination Temperature ~2500°K Convective Plasma (variable gas temperature is up to 1600°K) Heat Transfer Coefficient ~225W/m^2.K.(Compare to 10W/m^2.K) |

Example of Plasma Formation - N2+E

->N2++ e or Possible species include O2, N2, O2+ , N2+ , N, O, N+, O+, e−, in e-Ion Plasma of air Possible species include N2, , N2+ , N+, e− in the e-Ion Plasma of nitrogen. Almost all commonly employed elemental or molecular gasses/species can be ionized including Ar, Xe, H2O and others.

|

CleanElectricFlame™ Technology

e-Ion Plasma™ use compared to Combustion

CleanElectricFlame™. Nitrogen e-Ion Plasma™ Plume (possible species include N2, N2+ , N+, N, e-). Discharge is into room air conditions. Use for Nitinol or Ti6Al4V nitriding.

Issue |

Combustion Flame (Conventional Plume) |

MHI Advanced LIP System GEN 3 (CleanElectricFlame™ Plume) |

Emissions, Health & Environment |

|

|

Process Impact |

|

|

Explosion Hazards |

|

|

Energy Efficiency |

|

|

Control |

|

|

Noise |

|

|

Odor |

|

|

Cost of Operations |

|

|

Cascade e-Ion systems allow for continuous sintering (3Dsintering™) or hardfacing without the use of hydrogen. All ionic gasses are of a reducing kind.

Plasma polymerization of many unique polymers and blends and their surface deposits remain unexplored with this new method.