Active Metal Brazing - Ceramic Brazing

-

e-Ion Plasma™ Source -

e-Ion Zapper™ Furnace for Metals and Ceramic Uses -

GEN3 LIP System for Organic and Plastic uses -

What is e-Ion Technology? Thermal Plasma -

Plasma Ideation Brochure for Plastics

Conventional Limitations. Replace with Cascade e-Ion Processes.

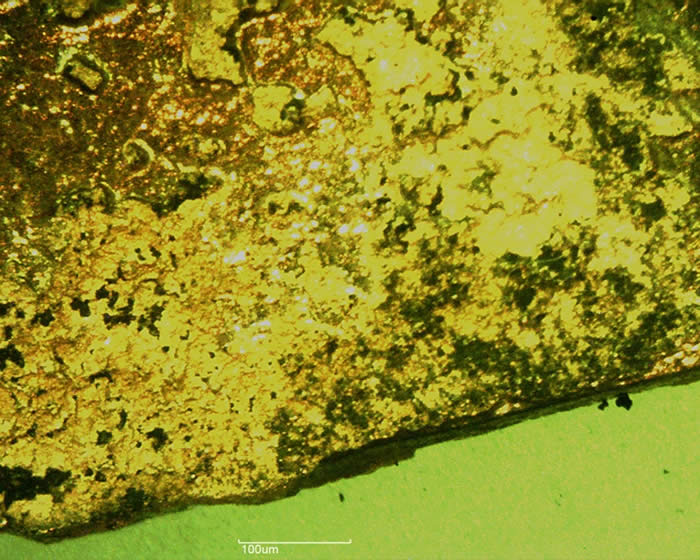

Having difficulty with copper flow with copper foil brazing on steel. Contact MHI to be astounted with what the e-ion can do even on "dirty surfaces". See below pictures of copper brazed to steel in air. No flux was used and the steel was pre-oxidized. 3DBrazing® is a registered trademark of MHI.

CleanElectricFlame copper flow on stainless in air

Active Metal Brazing and Ceramic Brazing Applications

Traditionally, brazing ceramics to metals and metals to ceramics has been particularly difficult. Just as when brazing ferrous to nonferrous metals, specific alloys and specialized brazing furnaces are required for successful ceramic to metal joining. These furnaces are large, expensive and typically suitable just for a few applications. This lack of adaptability has meant high initial capital costs, limited applications and high per piece costs.

e-Ion Plasma™ technology can facilitate ceramic brazing without issues typically faced by brazing furnaces or laser brazing.

- One Atmosphere Operations - No large enclosure is necessary to treat parts. The e-Ion Plasma™ can braze ceramics to metals, metals to ceramics, ceramics to ceramics and metals to metals without the typical requirements of a vacuum environment.

- Versatile - e-Ion Plasma™ can be repositioned with minimal effort, allowing for less downtime between batches and lower capital costs. (1 e-Ion Device may replace multiple specialized furnaces)

- Efficient - A combination of higher operating temperatures, lower energy consumption and patented technologies allows e-Ion Plasma™ to braze faster and more cost effectively than alternative technologies.

What makes brazing ceramics difficult is their lack of wettability. Simply put, it is difficult to ionically bond anything to ceramics. Plate metallization and thin film metalization can be effective in certain circumstances, but high tooling costs and size contraints limit widespread adoption. e-Ion Plasma™ devices are easily movable and can easily handle on-line/in-line processing, virtually eliminating size constraints typically found in existing technologies.