Having trouble reading this email? Click here to view on your browser

|

|||||||||||||||||||||||||||||||||||||||||||||

| Volume 1 Issue 13 | June 25, 2014 | |||||||||||||||||||||||||||||||||||||||||||||

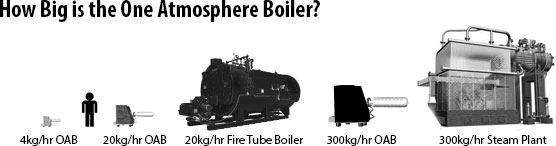

One Atmosphere Boiler (OABTM)High Capacity Superheated Steam up to 1300CPure, superheated steam without pressure. Our new One Atmosphere Boiler technology produces steam up to 1300°C within moments of being plugged in. Single phase, Three Phase and High Kilowatt Models feature Small Footprints and High Portability. Standard OABTM Features Include:

MHI Control Panels with optional DACS2, Graph Display and USB Port2

1Please contact MHI for more details about Never-Down Program  One Atmosphere Boiler

| |||||||||||||||||||||||||||||||||||||||||||||

| Model | Electrical Power/Exit Temperature | |

| OAB-4 | 4-6 Kg/hr Steam |

Single Phase from 300°C-1300°C |

| OAB-12 | 12 Kg/hr Steam |

Models from 300°C-1300°C |

| OAB-36 | 36 Kg/hr Steam

|

Models from 300°C-1300°C |

| OAB-48 | 48 Kg/hr Steam |

Models from 300°C-1300°C |

| OAB-60 | 60 Kg/hr Steam |

Models from 300°C-1300°C |

| Custom High - Steam Boiler Requirement | > 60 Kg/hr |

Models from 300°C-1300°C |

| Tankless T-OAB4 | 4 Kg/hr |

300-400°C |

| Tankless T-OAB12 | 12 Kg/hr |

300-400°C |

MHI's One Atmosphere Boiler superheated steam boiler features patented InstaSteamTM technology, allowing for rapid startup times, unparalleled efficiencies and up to 1300░C temperatures. BoilerFreeTM technology allows most OABTM units to be installed without the need for traditional boiler certifications.

Pure Steam. Clean Steam. OABTM generate superheated steam that is free of contaminants.

Highly Scalable. OABTM units can produce from 1kg/hr to over 1000 Kg/hr.

Efficient. Boiler efficiencies improve when operated at lower pressures. Better conversion factors allow OABTM units to use less resources to produce more steam. The OABTM's rapid start-up results in less energy used getting up to temperature. Lower operating costs, less downtime and higher productivity. Check Our ROI calculator

Better conversion factors allow OABTM units to use less resources to produce more steam. A standard OABTM steam output at 350░C is almost at the theoretical efficiency of power conversion for the OABTM steam generation! The OABTM's rapid start-up (generally with a minute from cold start) also adds considerably to the overall lowering of energy comsuption.

|

|

|

FEATURED PRODUCTS ON SALE

|

|

|

|

|

|

DID YOU KNOW? |

|

Did you know that almost 40-50 % of all energy used in the US involves steam? That's a lot. Compare impacted steam cleaning to pressure washers? One way to compare is from the energy content for the same weight of water. Pressure washers with water (hot or cold) deliver about 400-800 kJ/Kg whereas steam is 2500-3000 kJ/Kg. High temperature steam has more energy per unit weight compared to high pressure water or even mist. When in a fully gaseous state, steam like air, is invisible. If you really wanted to see the steam-mist you can lower the temperature into the mist range and turbo-charge the steam output to achieve the same result. This way, you can get the best of both worlds! Note that from an OABTM one already can get velocities in the order of 40 m/s. |

|

|

|

|

|

MHI Latest News |

|

|

|

|

|

|

Follow MHI |

|

|

| SEE MORE MHI-INC TECHNOLOGIES | ||||

Micropyretics Heaters International

750 Redna Terrace

Cincinnati, Ohio 45215

Tel: 513-772-0404 | Fax: 513-672-3333

Email: [email protected]

You are subscribed to receive Micropyretics Heaters International newsletter as: {EmailAddress}.

To remove your email address from our mailing list pleaseáclick here.

All rights reserved..