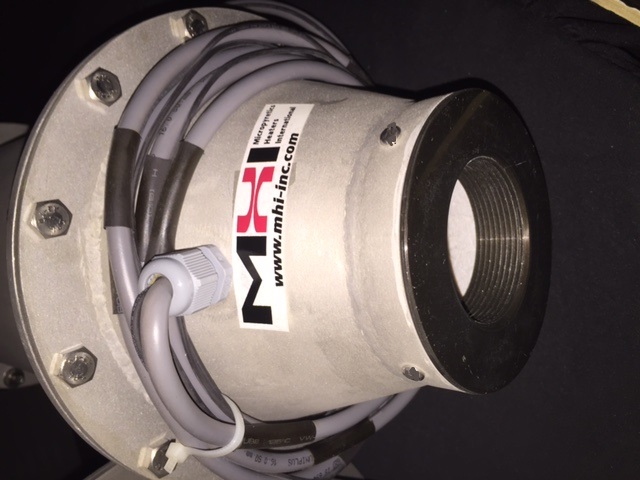

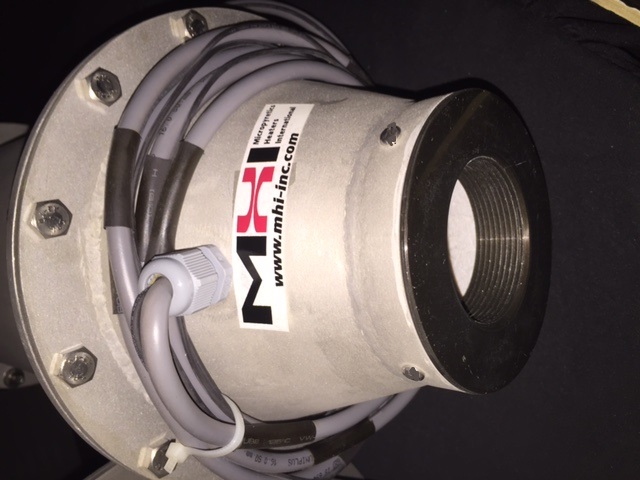

Schematic of Blowers and Air Flow Valves Provided by MHI

MHI Airtorch Systems are offered with variable inputs attachments that suit customer needs

Flow units are supplied with several safety features like the over temperature cut-off feature and the low flow cut-off feature

Please contact MHI for free die-heating Powerpoint presentation and ROI case studies. Blowers are considered in circumstances where larger pressure drops are present. Compressors are used when the pressure to be overcome is large.

Higher Power Models (MVTA and GTA Airtorch)

VTA models are highly energy efficient, allowing for less energy use and higher cost savings. VTA models are fully compatible with MHI electronic control panels, allowing for accurate control of flow rates and temperatures for your process. Suggested uses for these models include integration into existing heating systems for cable conveyors, drying, process heating, coatings, production line heat treating and a number of other specific process applications.

Schematic of Blowers and Air Flow Valves Provided by MHI

MHI Airtorch Systems are offered with variable inputs attachments that suit customer needs

|

Because of their versatility, MHI's Airtorches™ may be used in several applications. Because each application is unique, please contact us to discuss which product best fits your needs. VTAs offer full power transfer up to 900°C. Note that configuration for 750°C and 900°C may vary in compactness. For ultra-sealed units choose MVTA. For high pressure units please contact MHI as configurations vary with temperature. VTAs include an integrated Type "K" thermocouple. Most units are compatible with an optional control panel. Contact us or call us at 513-772-0404. VTA-BL models have integrated air/gas controls. 3-Phase VTAs require TRIPAN Control Panel. Dimensions are subject to change and exclude flow controls. VTA models are not designed to be as well sealed like MTA and MVTA models so should not be used with all gasses. VTA's are leak tight for air. VTA has low flow cut-off with extendable user interface. VTA also has full control features if required, please discuss with an MHI Representative. Fan control is available with the FANCS, which also includes temperature controller. |

10kW VTA900-10BL - Up to 900°C

4 kW VTA VTA750-4GS with fan |

| Model | Power | Voltage | Max Temp | Max CFM @ Max Temp | Diameter> | Height | Air Supply | Inlet Integrated with Fan or Inlet Accepts Blower | Exit | ||

| AIR CONNECTION | |||||||||||

| 4kW | 208/220/230/240 | Call | Call | 4.0" (100 mm) |

27.5" (698.5 mm) |

Fan model: MK4XL | Fan/Blower | 2" NPT | |||

| VTA900-10BL | 10kW | 208/220/230/240 | 900°C | Call | 7.0" (177.8 mm) |

27.5" (698.5 mm) |

Call | Blower | call | ||

| 3-Phase Custom | (high kW) | 240/440/480 | Variable 700 -1100°C |

Call/Contact | Call/Contact | Depends on Model | Typical 10-20 inches Diameter and about 50" Length. | ||||

| ** : FANCS: Fan speed controller and temperature indicator | |||||||||||

LTA

Up to 850°C

Designed for Compressed Air or Gas Inlet

|

LTA Models allow for easy idependent control of power and flow-rate. LTA Airtorches™ are to be used with compressed air and power controller. LTA's are highly energy efficient, but not used where complete sealing is require. LTA models are fully compatible with electronic control panels, allowing for accurate control of flow rates and temperatures for your process. Suggested uses for these models include integration into existing systems for cable conveyors, drying, process heating, coatings, production line heat treating and a number of other specific process applications. LTA models are not designed to be as well sealed like MTA and MVTA models so should not be used with all gasses. For sealed units please click to MVTA and MTA models. *At full power the minimum flow required is higher. This is also minimum airflow required when fully energized to rated kW. All LTA models feature an optional Temperature Indicator module. All LTA models feature an integrated Type K thermocouple. Note that dimensions are to be read within a standard tolerance. Flow Rate vs. Temperature Charts. MHI units feature a nearly 100% power transfer efficiency. Compressed Air/Gas Based (LTA) Compared to Blower Based (VTA) |

LTA750-04 |

| Nominal Power | Voltage | Maximum Rated Temperature | Nominal SCFM @ Max Temp, 60% Power*, 100% Power Approximate |

Control Panel (Recommended) |

Heat Tube Diameter | System Height | Air/Gas Supply | Inlet | Exit | |||

| 1kW | 115/120, Single Phase | 850°C | 1.4 SCFM, 1.8 SCFM | BPAN | 2.1" (53 mm) |

15.25" (387 mm) | Compressed Air | 1/4" NPT | 1/4" NPT | |||

| 2kW | 208/220/230/240, Single Phase (115/120 is Special Order) |

850°C | ~4.0 SCFM, 5.3 SCFM | BPAN | 3.3" (86 mm) |

14.75" (374mm) |

Compressed Air | 1/4" NPT | 1/2" NPT | |||

| 4kW | 220/230/240, Single Phase | 850°C | 8.0 SCFM, 11 SCFM | BPAN | 4.0" (100 mm) |

18.5" (470 mm) |

Compressed Air | 1/2" NPT | 2" NPT | |||

60kW

and higher available see MVTA, please call MHI at 513-772-0404 for more information contact us. |

||||||||||||

| LTA and VTA Accessories | ||

4kW VTA-4GS Integral fan Stainless steel casing |

Flow-control Module - Optional with BL Models |

(Discontinued Model) |

Minimum Flow detection and cut-off module supplied standard with VTA900-10BL |

1kW LTA |

4 kW LTA |

| FANCS Units & Adaptors (required with fan models) | ||

FANCS Control Unit |

FANCS Control Unit - Front |

Outlet Adaptor |

| LTA Airtorch™ Heater Accessories | |||||||||

| NPT Nozzle with fitting for pipe extension | |||||||||

| FS750-A - Adjustable flow rate detection valve and switch | |||||||||

| FS750 - Flow rate detection valve and switch | |||||||||

| FLM750 - Flowmeter 2-23 SCFM (click for larger images) | |||||||||

| FTB750-6 - 6' Air/gas supply tubing | |||||||||

Knife Nozzle (Not Available from MHI). Picture shown only for ideation. |

|||||||||

|

MTAR - Moisture trap ensures dry air to AirtorchTM | ||||||||