Description

LTA750-1INL Hot Air Generator Specifications: | |

| Model: | LTA750-1INL (110V, 1kW) Cartridge Type Hot Air Gun (inline type)  |

| Unit Description: | Model LTA750-1INL belongs to the Airtorch series of inline hot air tool devices, which can discharge continuous hot air from 200°C to 900°C. The unit may be used for Nitrogen and Oxygen or Air. The exit temperature is controlled by the flow rate and the electronic temperature/power adjustment control panel. This products specific performance withand without the control panel is discussed below. Typical use limitation without the electric control panel is restricted to below 800°C for the correct flow. Such hot air guns are used in plastic welding, heat shrinking of thermoplastics, ceramic drying, on-site heat treatment, plastic forming, and many other inline applications. The unique construction provides efficient heat recovery and management, providing high-efficiency hi-temperature discharge. If controls are not used and the unit is energized, a minimum flow of 51 slpm is required for 1 KW. A lower power input can be used. For a flow lower than 51 slm, one needs a control panel that limits power and temperature—like the BPAN-O-PLUS, which a is shown in tthe optional pull down menu. Dry Air: Without a control panel plugged into 110V. Common use 750C at (110V – 120V) plug-in at ~51 slm@full 1 KW power. For the highest exit temperatures a 120V supply is required. A flow meter and BPAN-PLUS are also required for safety and control at temperatures above 800C. Other settings: ~250C at 110V plug in at ~ 280 slm @ full 1 kW power Control Panel (optional): BPAN-O-PLUS-120 A control panel that limits power and temperature is required for flows lower than 50 slpm. A BPAN-O-PLUS control panel can be selected from the pull-down menu. Note: Parts of the surface are hotter than 50°C (DO NOT TOUCH). This unit is for inline stand-alone use. The Airtorch has an in-built Type “K” thermocouple and an available temperature read-out (optional). Flow generation into the Aitrorch should be with a compressor/or gas bottle and a flow meter, both in the user scope. Optional BPAN-O-PLUS and TC Read display. These are shown in the pull-down menu. This unit’s minimum flow for air at full power is 1.8 SCFM (~51 SLM). The flow settings vary for other gases. The input gas should not exceed 60C. If less than minimum flow is maintained – please use a lower power setting than 1 KW and low appropriate flow. This can be done by proportionately reducing the voltage or using the BPAN-O-PLUS Controller. When the BPAN-O-PLUS is purchased, the power can be reduced by ~50%. Below that power, a high temperature may not be achieved. The flow has to be correspondingly adjusted. |

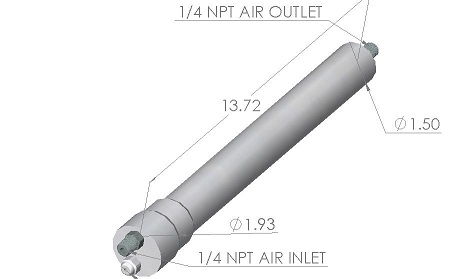

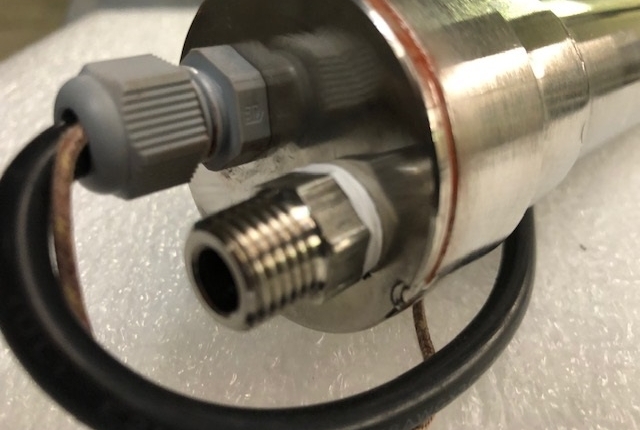

| Dimensions: | Unit: 1.5″ dia x 15.25″ L. The Ccollar is 1.95″ dia. Air inlet: 1/4″ NPT male fitting |

| Weight: | Lightweight with a compact, ergonomic design |

| Temperature: | 750C/800°C continuous airflow. It can be used carefully in an intermittant mode to higher temperatures like 900C but this should be done very carefully. Please contact MHI. |

| Airflow: | The minimum required is 1.8 CFM at the inlet at max power for a 120V plug-in. Adjust the flow meter (optional) to get minimum airflow The unit may burn and fail if minimum airflow is not provided for any power setting.For lower than 51 slpm flows, the power can be reduced with a BPAN-O-PLUS which permits lowering of total power. |

| Voltage: | 110/120V VAC |

| Frequency: | 50/60 HZ |

| Current: | Approx. 9 Amps @ 110VAC |

| Power Consumption: | ~1000 Watts |

| Output Power Control: | Remove plug – no switch provided |

| Handle: | None. |

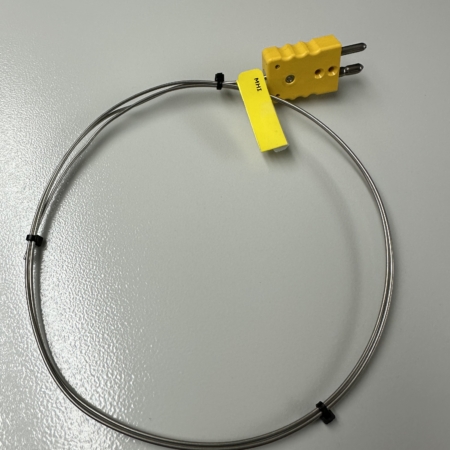

| Optional Accessories: BPAN-O-PLUS and TC-READ (Pictures shown above) | Note the unit has its thermocouple. Power controller BPAN-O-PLUS (120V) is an option for power control. This interfaces with the built-in thermocouple. The TC READ purchase includes an additional K- thermocouple and its stand (TC Read+TC+STAND) or can be used with the BPAN-O-PLUS power controller (optional). The Built-in thermocouple can also be connected to the optional TC Read system for an external display. The TC-Read unit plugs into a 115/120V single-phase socket. Optional: 3 1/2″ LCD display switchable between °C and °F (TC Read) |

THE MINIMUM AIRFLOW REQUIRED FOR SAFE USE IS ~1.8 SCFM OR MORE. PLEASE NOTE UNLIKE MTA’S, the LTA’s are not fully sealed. FULLY sealed units are classified as MTA models. Please link to the LTA page for more information.

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA MHI Inc

MHI Inc

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA