Airtorch™ Applications |

| Airtorch™ System Introduction |

Choose the right LTA or AT for your applications and experience greater

flexibility with your operations.

(Choose the power required first, the power will determine the flow available at the intended temperature

Approximate quick back-of-the envelope calculation. First asses the power required, then employ the following design criteria ~ about 2.6 SCFM/kW.

Call MHI for confirmation as this is an approximate number only and should not be used for detailed design. MHI applications specialists will guide you through the process.

Choose the temperature desired from the information below which will direct you towards the model(s) to choose from

|

Roll over the maximum

temperature of your application and click on a product to view details. Choice |

||||||||

MTA 60kW |

|

|||||||

____________________________________________________________________________________________________

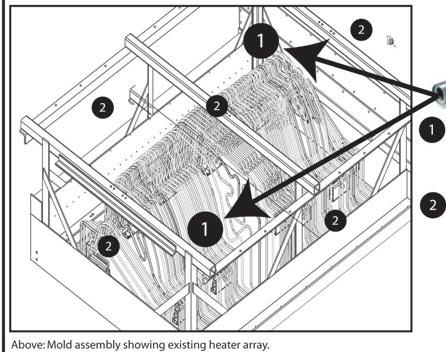

Example of a 4kW Airtorch™ augmentaion application. In this application, many complex shaped rods are to be heated uniformly. The heat-treater reported that the rods were not uniformly heated in his existing radiant heat furnace. MHI proposed a add-on to his existing furnace with a system of airtorches which then greatly impacted the uniformity and reduced the total energy consumed. More Green Installation and more Profits to the user. Impove oven performances and eliminate bad emissions.

Airtorch | AT-PV | GTA | LTA | VTA | SLTA | MTA925 | Plasma | Ultra |

||||||||

Airtorch™ Applications 2

Nozzle

Heating |

Gas

Preheating |

The

glass industry uses the high temperature Airtorch™ to enable

uniform flow and reflow of molten glass. The air temperature can

be as high as 1200°C with a very low flow rate.

|

Airtorch™

can be used to rapidly heat various atmospheres: Air, Nitrogen,

Argon, Helium, etc. Call MHI for more information.

|

Microprocessor

Heating |

Light

Fiber Processing |

Unique

heating from 500°C to 1000°C. The Airtorch™ produces

laser-like heat to small areas down to 5mm in diameter with stable

and accurate control.

|

Uniformly

free carbon from woven fibers with true convection. The Airtorch™

creates hot turbulent air that passes through the substrate for

uniform and accurate heating. As carbon is released, the natural

flow of clean hot air flushes the airborne carbon away from the

part and up the chimney.

|

Effective

Heat Treating |

Preheating

for Welding |

Uniform

rapid heating. The Airtorch™ offers uniform high temperature

and heat transfer to rapidly heat parts. Very effective for metals

when increasing hardness.

|

With

high accuracy and temperatures, the Airtorch™ reduces the

guess work out of preheating for welding applications. Offers accurate

temperature read-out.

|

Spot

Decarborinzing (reducing hardness) |

Ultimate

Utility |

Over

carbonizing causes hardness above most machining capabilities. The

Airtorch™ offers locatable, accurate rapid heat-up and cool

down to efficiency diffuse carbon allowing tempering of the metal.

|

Develop

your own application. The Airtorch™ is capable of many applications

where accuracy, uniformity, power and high temperatures are required.

Also benefit from whisper-like operations, energy efficiency, and

ease of use.

|

Special

Convective Ovens are also available.

Ideal for moving parts(debind, degrease, remove paint, etc.)

| Go to AirtorchT Belt Ovens Prices |