e-Ion Plasma™ - Thermal Plasma Generator

3Dsintering™, 3Dbrazing™, and a multitutude of 3Dheat-treating™ within a few minutes

Improve materials propertis like wear, strenght, erosion, fatigue, hardness, creep, reflectivity, emissivity and others

Use low cost mhi rapid gas processing and save money

3Dsintering™, 3Dbrazing™, and 3Dheat-treating™ are trademarks of MHI Inc. recognized in many parts of the world

What is e-Ion Plasma™? - Features of Plasma (Brochure) - Extremely Wide Area Plasma (with LIP)

The unique e-Ion Plasma™ allows for unique applications of Ions, Electrons, Radiation and Hot Gases. The e-Ion Plasma™ produces a CleanElectricFlame™. This thermal plasma technology platform offers clean-green technology that can use just electricity and air, leaving behind no residues. It is a new alternative to electron, laser, induction, and other Rapid Thermal Process heating methods. MHI's e-Ion Plasma™ uses less energy, produces less noise and is safer than traditional heating methods. All e-Ion Plasma™ devices feature integrated patented technologies developed by MHI. Other features

of e-Ion Plasma™ include: Highly efficient low power consumption, no water cooling, no ground electrode required and very small foot print.

Plasma polymerization of many unique polymers and blends and their surface deposits

remain unexplored with this new method.

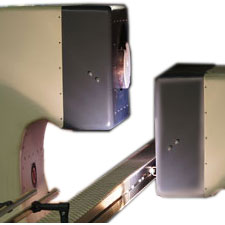

e-Ion Plasma™ Source | e-Ion Zapper™ Furnace | Gen3 LIP System

|

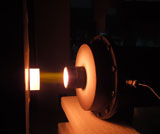

Picture above is air plume below e-Ion Plasma™ Nitrogen Plume Dicharge is into room air conditions |

Scalable Construction Use for Nanostructuring Hard Surfaces |

Improve Plastic Bottle Aesthetics. Glossier Appearances. |

Live Demo

Rapid Sintering of 3-D Printed Products. Use e-ion enhanced systems to rapidly sinter, hardface and clean. Cut time from 36 hours to few minutes in some cases.

Systems available for rapid sintering of platics, metals, ceramics and composities.

Please Contact MHI to schedule a live demonstration on your part. Demonstrations can be given live on SKYPE or equivalent.

Simply contact us. Send us your part and let us demonstrate the results live.

Helpful recomendations: Consider Zapper and Magnifiers for metals and ceramic. Use e-ion LIP or OAB for polymer 3D sintering.

Yes, even titanium can be sintered within minutes from start to finish. Extremely shiny parts even for copper or tungstan-copper.

Plasma Uses

MHI's unique e-Ion Plasma™ features novel technology that allows it to replace existing processes while simultaneously improving efficiency and productivity. Immerse in CleanElectricFlame™ for non line-of-sight processing or bend-heat requirements. Compare with Laser.

| e-Ion Plasma™ Uses | |

| Rapid Degreasing and Stripping | Rapid Deburring and Smoothing from Metals to Plastics. Smooth Finishing. |

| Nickel or Cobalt Alloy Brazing and Hardfacing (call for details) | Surface treatment without grounding object. Connect to gas and electric. |

Plastic Surface Functional Manipulation (please download ideation brochure). Plasma Ideation Brochure.

|

Heat Treatment for hardening and other processes. Please click on comparison tabs above. |

| Denaturing | Decontamination |

Electron beam replacement |

Corona Alternative |

Electron Beam Furnace |

Smoothing and conditioning. |

| Compare to electron beam or laser welding | Cleaning extruded plastics. Avoid toxic chemicals. Unique power adjustments possible. Plasma Ideation Brochure. |

Compare to electron or laser beam Melting |

Induction Heat Treating |

Improving surface adhesion. Cause functionalization. |

Compare to Induction Heat Treating |

EB Welding support Extremely Wide Area Plasma (with LIP) |

Compare to Induction Melting. Please download aluminum processing brochure, |

| Laser Welding support | Surface Cleaning |

| Enable Plastic Welding | Enable Seam Welding. Dissimilar Materials. |

| Thin Film Deposition | Deposition |

| Rapid Annealing | Rapid Thermal Processing |

Surface Deposition

Comparison of Surface Deposition Techniques

| e-Ion Plasma™ | Laser | Electron Beam | |

Deposit Rate |

Very high, continuous | Medium | Medium, discontinuous |

Species Deposited |

Atoms and Ions | Atoms and Ions | Mostly Atoms |

Complex Shaped Objects |

Good/Excellent, varying uniformity | Good | Poor, based on line of sight |

Alloy Depositing |

Yes | Yes | Yes |

Simultaneous Gas Heating |

Yes | No | No |

| Substrate Heating | Yes | Low | Yes |

Compare with Laser, E-beam and Sunlight

Comparisons with directed energy systems (Laser to Sunlight)

| e-Ion Plasma™ | Laser | Electron Beam | Sunlight | |

Surface Impact |

Beam up to 150mm, large impact, improves productivity. Large area allows for CleanElectricFlame soaking at various power settings. | Commonly available average beam size is less than 2mm | Commonly less than 0.5mm beam | Varies |

Welding/Joining |

Yes, even for dissimilar materials | Yes, limited by beam parameters | Yes, limited by beam parameters | N/A |

Drilling |

N/A | Yes | Yes | |

Vacuum Always Required? |

No. Plasmize Air to cut down on cost of input gas. | No | Yes | |

Power Density |

106-109 W/m2 | 106-108 W/m2 for commonly used industrial CO2 continuous lasers. Depends on laser type. | ~106 W/m2 Depends on acceleration voltage and wavelength of beam | 1.3x103 W/m2 (average) |

| Water Requirement | None. High Energy Efficiency. | High | High | N/A |

Energy Efficiency |

Very high | Very low | Very low | N/A |

CleanElectricFlame™

e-Ion Plasma™ use compared to Combustion

CleanElectricFlame™ Nitrogen e-Ion Plasma™ Plume

Issue |

Combustion Flame (Conventional Plume) |

MHI Advanced LIP System GEN 3 (CleanElectricFlame™ Plume) |

Emissions, Health & Environment |

|

|

Process Impact |

|

|

Explosion Hazards |

|

|

Energy Efficiency |

|

|

Control |

|

|

Noise |

|

|

Odor |

|

|

Cost of Operations |

|

|

Request Information Online, Email-Us or Call 513-772-0404 for More Information

Compare with Induction

Comparisons with Induction

| e-Ion Plasma™ | Induction Heating | |

Surface Impact |

Beam up to 150mm, large impact, improves productivity. Large area allows for CleanElectricFlame soaking at various power settings. | Needs coupling frequency |

Welding/Joining |

Yes, even for dissimilar materials | Sometimes. Dissimilar materials are very tough to weld |

Drilling |

N/A | N?A |

Power Density |

106-109 W/m2 | Depends on frequency, coupling and coil details. |

| Water Requirement | None. High Energy Efficiency. | High |

Energy Efficiency |

Very high | Very low |

Learn how e-Ion Plasma™ technology can improve your business. Download Plasma Applications for Aluminum Supplement.

You may also view the general benefits and uses of e-Ion Plasma™ technology in the Plasma Ideation Brochure.