Continuous Rapid Brazing Made Easy

Good flow, excellent bonding, and hard surfacing as desired

The Cascade e-Ion Plasma™ may be used for high production volume brazing. Please consider for interconnects, simultaneous nitriding, oxynitriding, oxycarbonitriding, or sintering and hardfacing operations with the CleanElectricFlame®

3DBrazing® and 4DSintering® are registered trademarks of MHI

The heat-up rate is high.

The alloys that can be considered for Brazing even with plasmized-air are conducive for high-quality Brazing or joining type uses.

The CleanElectricFlame® does not use combustion. Some of the typical easy-to-use Brazing-Jigs and part manipulators are shown below. Rapid Brazing of metal ceramic-no flux is required often because the beam protects against oxidation. Using just air/gas and electric one considerably reduces energy usage in Brazing while contributing to clean, no-emission processes. Joining electrical leads is now easy and cost-effective. Eliminate open combustion flames

Switching to cascade e-ion for your brazing applications is easy and energy efficient. It also improves productivity, integrates easily into manufacturing lines, and eliminates open flames. This table compares the Cascade e-ion to combustion, lasers, and other heating devices. Consider less than a cent per part in cascade e-ion consumable. Ions clean the surfaces simultaneously with Brazing. Dissimilar metals like aluminum and iron or metal-ceramic composites are often easy to braze/join with the e-Ion Plasma™ machine. Comprehensive control systems are available which have been field-tested for over fifteen years.

Brazing made easy—the easy spreading of brazing alloy.

Traditionally, brazing ceramics to metals and metals to ceramics has been difficult. Similar to Brazing ferrous to nonferrous metals, specific alloys, and specialized brazing furnaces are required for successful ceramic to metal joining. These furnaces are large, expensive, and typically suitable for a few applications. This lack of adaptability has meant high initial capital costs, limited applications, and high per-piece costs. Please consider the Cascade e-ion as the modern alternative.

![]()

![]()

![]()

![]()

![]()

![]()

Easy flow of brazing alloy. ” I was impressed to see the clean and high integrity interface between WC-Co and stainless steel… .The technology of the .. e-ion Plasma seems to be great”.

Shiny Surfaces post Brazing.

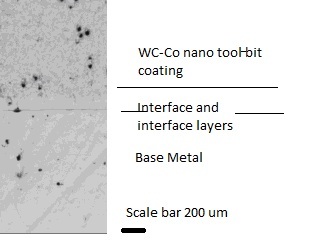

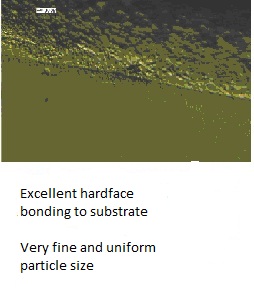

Below are typical hardfacing interface microstructures obtained with tungsten carbide nano and hardfacing/hard surfacing alloy on a stainless steel substrate. Wear-resistant surfaces may be made within seconds or minutes with the Cascade e-Ion Plasma by immersing in Plume, representing an increase of over 100-fold in productivity with lower capital cost and operating costs. Please contact MHI for details.

Nano-grained cemented tungsten carbide (n-WC) is currently being researched for many potential applications. Competitive processes are often noted to produce much coarser microstructures. The surfaces below of n-WC were obtained after short exposure to CleanElectricFlame™.

Cascade e-Ion treated parts: Micrographs of n-WC (left) and NiCoMo Hardfacing braze alloy to steel(right). MHI will be happy to provide process guidelines, and special aluminizing or boriding pastes as required.

Typical Comments: The high-speed, high-temperature ramp is very helpful. As per our discussion with the braze alloy manufacturer, one significant problem often faced is the microstructure coarseness because of many hours at high temperatures (typical to traditional multi-hour furnace brazing cycles). This is the cause for the tungsten carbide particle size to increase during traditional furnace heat-treatment sequences, and then the metallurgical bond integrity reduces drastically. Similarly, any boron carbide particles remain extremely small and well-bonded, as do nano-alumina after the bonding. Rapid heat-up and rapid cool-down are a must for the future. “One-minute hardfacing operation replaces 48 hr. operations! We also do not need nitrogen or argon atmosphere.” “What I like about the Cascade e-ion process is that it allows for rapid continuous production instead of batch production. Tool bit bonding by Brazing is efficient. With the Cascade e-Ion, the high integrity of the tungsten (carbide) alloy fusion bond with the base steel is very acceptable. When the bond is of such high integrity and tough (i.e., it does not activate or allow cracks to propagate), one can quench rapidly after the e-Ion CleanElectricFlame™ exposure. |  3DBrazing® High Integrity Bond for Hardfacing and Tool bits. Savings of considerable time and energy. Please ask MHI for ROI Calculator. |  Tool bit bonding by Brazing is efficient. With the Cascade e-Ion, the high integrity of the tungsten (carbide) alloy fusion bond with the base steel is very acceptable. When the bond is of such high integrity and tough (i.e., it does not activate or allow cracks to propagate), one can quench rapidly after the e-Ion CleanElectricFlame™ exposure. |

Conventional Limitations. Replace with Cascade e-Ion Processes.

Having difficulty with the copper flow with copper foil brazing on steel. Contact MHI to be astounded with what the e-ion can do even on “dirty surfaces.” 3DBrazing® is a registered trademark of MHI. Flux can be avoided.

![]()

CleanElectricFlame copper flow on stainless in air

Active Metal Brazing and Ceramic Brazing Applications

Cascade e-Ion Plasma™ technology can facilitate ceramic Brazing without issues typically faced by brazing furnaces or laser brazing.

- One Atmosphere Operations – No large enclosure is necessary to treat parts. The e-Ion Plasma™ can braze ceramics to metals, metals to ceramics, ceramics to ceramics, and metals to metals without the typical requirements of a vacuum environment.

- Versatile – The cascade e-Ion Plasma™ can be repositioned with minimal effort, allowing for less downtime between batches and lower capital costs. (1 e-Ion Device may replace multiple specialized furnaces). Efficient suction of active braze.

- Efficient – A combination of higher operating temperatures, lowered energy consumption, and patented technologies allow the Cascade e-Ion Plasma™ to braze faster and more cost-effective than alternative technologies.

Consider for metal-ceramic joining. What makes brazing ceramics difficult is their lack of wettability. Simply put, it is difficult to ionically bond anything to ceramics. Plate metallization and thin film metalization can be effective in certain circumstances, but high tooling costs and size constraints limit widespread adoption. E-Ion Plasma™ devices are movable and can easily handle online/in-line processing, virtually eliminating size constraints typically in existing technologies. We wish to braze efficient and low-cost connectors to silicon nitride. Contact MHI for the unrestricted use of a patent under special circumstances. Igniter.

Brazing Alloys and the Cascade e-Ion Plasma™ method

| Titanium (Ti) brazing early stages of compressor or exhaust | Dissimilar Metal/Ceramic Brazing | Nickel copper 59 Ni |

| New braze compositions | Platinum | Palladium |

| New engine crack repair | Braze Alloy | Au-6 (Gold) |

| Compressor Parts | Hastelloy, Inconel, Waspalloy | Iron Boron Silicon |

| Auxiliary Power Unit (APU) | Implants | Nickel Boron Silicon |

| Fuel systems/compressor inlets | 304 ss or Inconel 600, 625, or RA alloys | Gold 82/Nickel 18 alloy) |

| High compressor and low turbine | Stainless Steel | micro-36-M |

| Fuel systems leak proof braze | 304 ss or Inconel 600, 625 or 718 | NiCroly Ni-Cr-Al, Ni-Al |

| MRO engine repair hot section/high-pressure turbine. Abradable Tip | Superalloys of Nickel and Cobalt Biomedical Grade alloys | Presintered preform, paste, paint (PSP) |

| Fuel systems | Low temp like fuel systems | Silcoro-75 |

| Low-pressure compressor/Ti brazing | Ti-6Al-4V with Mo and other Ti alloys | TiCuNi and Shape Memory Alloys |