Cascade e-Ion vs. Lasers

Comparisons

Comparisons with directed energy beam systems (Laser, Electron Beam to Sunlight). The CleanElectricFlame® can be used as a narrow or wide area source (beam). Some comparisons between Laser and Sunlight are provided.

(All information in general comparison tables like the ones shown below should only be treated as approximate or indicative of order of magnitude.)

| Cascade e-Ion Plasma™ | Laser | Electron Beam | Microwave | Induction | Sunlight | |||||||||||||

| Surface Impact | The beam’s 250mm diameter significantly impacts productivity and improves efficiency. The large area allows for CleanElectricFlame® soaking at various power settings. | The commonly available average beam size is about 2mm | Commonly, less than 0.5mm beam | Poor | Depth varies with the frequency of the machine. | Varies | ||||||||||||

| Welding/Joining | Yes, even for dissimilar materials | Yes, limited by beam parameters | Yes, limited by beam parameters | Scarce possibilities | No for non-metals or poor electrical conductors like ceramics or plastics Yes, when metallic. Coils need to couple and sometimes be formed into complex shapes. | Relative Cost of Gas. Compared to Air

| ||||||||||||

| Drilling | – | Yes | Yes | No | ||||||||||||||

| Vacuum Always Required? | No vacuum is required. Plasmize air or other gases. | No | Yes | No It cannot be used with metal. | ||||||||||||||

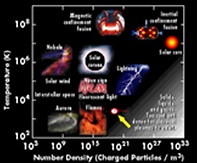

| Power Density |  106-109 W/m2 | 106-108 W/m2 for commonly used industrial CO2 continuous lasers. Depends on the laser type. | ~106 W/m2 Depends on acceleration voltage and wavelength of the beam | Low: about 1 to 2 kW for the entire chamber.�Power density is low for the surface. Bulk volume dominates as a major term for power density. | Efficiency depends on coil spacing, frequency, and type of materials kept in the coil. | 1.3 x103 W/m2 (average) | ||||||||||||

| Water Requirement | None. Adds to High Energy Efficiency. | High | High | No | Extremely high | N/A | ||||||||||||

| Energy Efficiency | Very high | Very low | Very low | Variable | Very Low | N/A |

The relative price to use a gas or maintain a vacuum is above. The SmartPlasma(TM) Cascade e-Ion machine can use air as the gas input.

Surface Deposition Comparisons

| Cascade de-e-Ion Plasma™ | Laser | Electron Beam | |

| Deposit Rate | Very high, continuous, and flexible for even Colloids and gels. | Medium | Medium, discontinuous |

| Species Deposited | Atoms and Ions. | Atoms and Ions | Mostly Atoms |

| Complex Shaped Objects | Good/Excellent, varying uniformity | Good | Poor, based on line of sight |

| Alloy Depositing | Yes | Yes | Yes |

| Simultaneous Gas Heating | Yes | No | No |

| Substrate Heating | Yes | Low | Yes |

| Operational Costs and Capital Cost | Small | High | High |

The relative price to use a gas or maintain a vacuum is above. The innovative Cascade e-Ion machine can be used with air as the gas input.

Comparison Price with Conventional Batch Type Ion Nitriding Machine

| Type | Conventional RF Type Small Volume | Conventional RF Type Mid-Volume | Cascade e-Ion System |

| Working volume, m3 Price* (*We encourage users to compare prices independently, as discounts, exchange rates, and other issues may impact the prices discussed.) This table shows only rough estimates. | 0.1m3 (~3.5 cu. ft). Price about $100,000 | 10m3 (~350 cu. ft) Prices start at $500,000 | Unlimited Volume |

| Working surface diameter x height estimate | 500 mm by 610 mm | 1100 mm by 5100 mm | Unlimited because it is disconnected from machine features. |

| Draw to Part Power Efficiency | 1-5 % typical | over 90% typical | |

| Typical Machine | ~20 / 25 kW | ~200 kW 200kW operational price is about US$32000 per 200 days/ year @10¢/KWhr and 8 hrs of use per day | From 3kW-20kW. Several Powers are offered. |

| Working gases | Mostly inert or nonoxidizing. Nitrogen, hydrogen, ammonia, propane, natural gas, methane, argon | This includes air and steam nitrogen and other elements as required. | |

| Typical Operation Pressure | 1 – 8 millibar. Vacuum required. Costly. | No Vacuum Requirement. 1 atmosphere | |