Fiber Heaters and Multiaxial Stands

Fibheat with Multiaxial Stand

fiber-heaters (decarbonized)

Fiber heaters process optical fibers and composite wires that can be inserted into the Fibheat units through the lateral slot (gap). See the pictures below.

What are Fiber heaters used for? Tapering, fiber couplers, selective heating, and joining.

What is tapering of fibers? Tapering of fibers, e.g., optical fibers, is done by heating a small fiber region to a high temperature while the fiber is gently stretched as evenly as possible. Tapering reduces the diameter of the fiber and heated core.

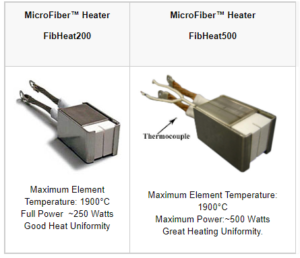

MicroFiber™ Heater FibHeat200 | Fiber Heater FibHeat500 | X-Ray or Neutron Port Enabled MicroFiber™ Heater FibHeat200-THM-XRD | X-Ray or Neutron Port Enabled MicroFiber™ Heater FibHeat500-THM-XRD | IG Fiber Heater HEAT-1″ Zone |

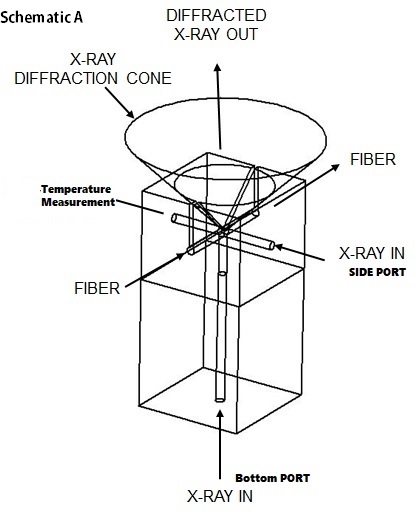

Maximum Element Temperature: 1900°C |  Maximum Element Temperature: 1900°C | Maximum Element Temperature: 1900°C Schematic A type shown | Element Temperature: 1900°C Schematic B is shown |  Maximum Element Temperature: 1450°C Total Power: 120 Watts. |

12mm Zone The base of the slot can have a user-defined hole profile, as shown below. | 25+mm Zone | 12mm Zone and half Slot or full slot plus an orthogonal hole.* | ***Large 25 mm Zone | 3-20 mm depending on temperature |

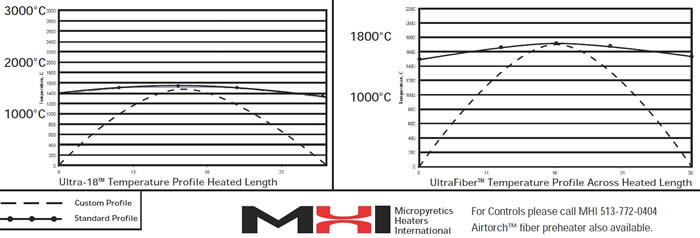

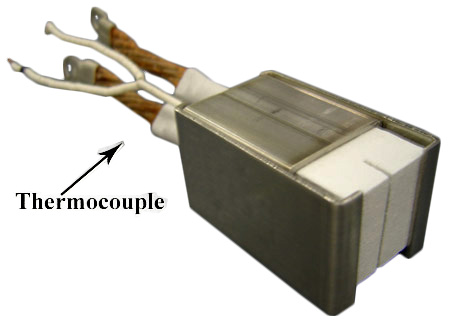

MHI Fiber Heaters may be used with the stand below in horizontal and vertical orientations. The Fiber Heaters are beneficial for optical fiber processing, especially fiber coupler fabrication or coning. Dimensions are available by calling 513-772-0404 or clicking on Contact Us. The heated fiber temperature will typically be lower than the heating element temperature (depending on the fiber). Thermocouples are not shown in the pictures above but in the image below. Thermocouples are included. Specialty FibHeat200-XRD model Fiber Microheater with Fiber-Heater is available. X-Ray and Neutron Beam Ports for high-temperature testing are shown below. Photonic materials processing/testing is feasible. Note that high-power units have slightly slanted slots to accommodate multidirectional use ports. MHI provides a custom calibration curve for your application. Nominal uniformity profiles (only when available) are also available by contacting us. All MHI Fiber Heaters utilize MHI’s patented heating elements. Note that slot and hole directions are interchanged in the 75mm version. See further below for more description. With over-temperature protection, MHI’s BPAN-O-PLUS and Data Acquisition System closed-loop control system is available for MicroFiber™ Heaters and Fiber Heaters. Compare the price with the online form below. Please visit the testimonials page for references./ MHI Control Panels will be shown on the quote when requested. Please inquire about UL and cUL – no NOx burners. Decarbonized Product. | ||||

The thermocouple location is shown in the photograph below. Please note that the exact location differs between models or may be located to not interfere with a sample or a beam. A typical MHI multi-axis flexible stand for the fiber heaters is shown below.

The profile varies with installation and fiber slot sizes. It is very uniform – regardless, the ends can be cooled to get sharper drops.

MHI Flexible Stand with Easy Connectors. MHI Multipurpose (and Multi-axis) Stand with Thermocouple shown.

Also shown is the new Spot Heater

| SPOT HEATER | IGNITOR |

Spot Heater | |

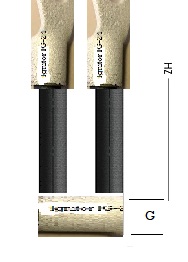

| Small Microheater. IG24-400-1400 Temperature typical 1400°C (2552°F). Low Amps, High Temperature. Materials GAXP-IgMp Hot Zone >1″  Robust Ignitor 1″x ~1″ x 1/2″ envelope Robust Ignito Square-U shaped. G is ~10mm. Hz is 12mm. The total length can be customized. The standard minimum length is 25mm. IG24 Microheater 1400°CRapidly heat – very high rate 20-600C per second. It takes about 10 seconds to glow temperature. |