Description

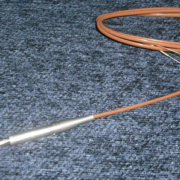

Average Size 3mm * (Range 0.5 – 4mm)

FRACTALBALLS™

May be used as thermal insulation, chemical substrates, or structural materials when bonded with FRACTAL PASTE™ or FRACTALGLUE™.

Use as thermal insulation: FRACTALBALLS have very low density, low thermal conductivity, high strength, and high melting point; as they are free flowing they can be formed into any shape and size and be used for refractory/insulation parts creation (to form a rigid part they have to be mixed with fractalpase and fired in a furnace after drying).

Typical applications: thermal insulation, fire protection and stops, high-temperature furnace linings, widespread and gas combustion burners. A very common use is for repairing or relining refractory cracks and holes.

Use for high surface reactivity: FRACTALBALLS have very high porosity/low density, high strength, and high melting point. They may be used for high-temperature filter and membrane substrate applications.

Typical applications: Lightweight structure materials. Composite manufacture reinforcement additive for metal, ceramic, or polymer. Armor, bio-ceramic, abrasive brake pads etc. Coatings for surfaces (Metals, Ceramics, polymers.)

Other typical applications: Filter molten metal castings (aluminum, copper, iron). Steam cleaning. Apply as lightweight coatings or Oil trapping and recovery grease filters. Chemical and water purification processes. Hot-gas filter substrates for electrodes. Electronic substrates carriers for bioreactors. Desiccants Substrates for catalytic converters. Usage as lightweight structural materials. FRACTALBALL has a unique microstructure, very low density, high strength, and high hardness.

All trademarks on this document belong to MHI Inc.

FRACTALBALL is a unique, lightweight, non-hollow porous ball with a very low density and high strength. The FRACTALBALLS (HMG1) material has excellent heat, chemical, and mechanical stability; the spheres have low thermal conductivity and high thermal shock resistance. The spheres are sold in a fully fired condition with excellent dimensional stability up to 1900C. FRACTALBALLS are environmental-friendly materials: they do not contain any hazardous materials such as organic volatents or fibrous materials and will not produce any smoke or odor when heated. They also have desirable chemical, physical and mechanical properties, such as inertness to chemical attack (solvents, acids, alkalies, and detergents), non-wettability by molten metals such as aluminum, and high thermal stability, high strength, and microbiological stability. These features permit the FRACTALBALLS to be used in various applications.

FRACTALBALLS, made from the HMG1 material, may be used in loose stacked form or bonded into any size and shape part by bonding the FRACTALBALLS with FRACTALGLUE. Normally supplied as hydrophobic surface. Special orders can be made to change this to hydrophilic. These flexible processing possibilities allow FRACTALBALLS to be use in various applications.

Properties of Material HMG1 – Color – White Nominal Composition,wt % Mullite – 90% Al203 – 10% Other Metal – less than 1% Ball Density, g/cc – 1.0 Stacked Density,g/cc – 0.7 Diameter,mm – (major range 1-4 mm) Maximum Use Temperature,°C -1900° C Ball Porosity, 70 % (average) – 70 Strength – Each 3mm ball supports approximately 10Kg of Load. High Strength.

FRACTALBALLS have a porosity of about 70%; when loosely stacked, the porosity is about 85%; Fractalglue bonded Fractalballs have a porosity of 75%, whereas FRACTALINS have a porosity of about 80%. Factallballs glued with Fractalglue has a strength of 5MPa, whereas FRACTALINS has a strength of about 6MPa.

The composition of HMG1 material is given by clicking on the Technical Data link above. MSDS sheets may also be downloaded from the site. Patents Applied For And Pending. FRACTALBALLS, FRACTALINS, FRACTALGLUE, FIBERFREE, and FRACTALBALL are trademarks.

FRACTALBALLS, which are made from the HMG1 material may be used in loose stacked form or bonded into any size and shape part by bonding the FRACTALBALLS with FRACTALGLUE. These flexible processing possibilities allow FRACTALBALLS to be used in various applications.

MHI Inc

MHI Inc MHI

MHI

MHI INC USA

MHI INC USA

MHI Inc. USA

MHI Inc. USA