High Temperature Anti-Seize Bearings, Bolts and Bushings

Anti Seize Treatment against Galling, Corrosion and Wear Temperature Range: Liquid Nitrogen to 3000F?

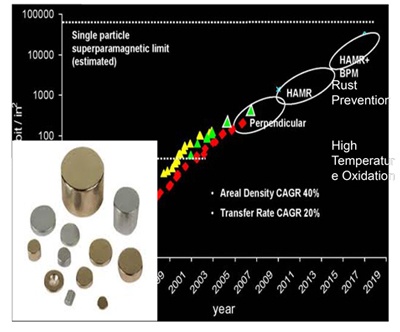

Build Corrosion protection layer on Ferritic, Titanium and Zirconium Alloys. Considerably reduce acqueous corrosion at a range of pH for NdFeB magnets, Samarium Cobalt and other rare earth magnets. When Cascade e-ion beam is passed over a rusted object as it then creates a hard protective layer.

Improve corrosion of mild steel, EN, DIN and SAE designations by the Cascade e-ion treatment.

Make lower coefficient of friction surfaces on on gears both large and small (such as in watches). Improve glass curvature and smoothness.

Metallic anti-seize GoldenBlue™ provides superior protection against galling, corrosion, heat freeze, rust and seizing on many types of metal surfaces. Use in oxidative conditions as well as reducing conditions. Smooth, hard and high lubricity.

The pulp and paper and food industry also use polymer coated rollers and often make them anti-stick with polymer or cermets. The GoldenBlue&trade treatment could be a new coating technique to provide permanent low friction and heat and wear resistance. Typical treatment time would add one US cent per part for rollers and trays. Regardless this aspect should be tested on a case by case basis – which MHI will do free of cost while the program is offered. Imagine if soft coatings are replaced by the hard smooth wear resistant GoldenBlue™ at your own site with the Cascade e-Ion machines.

| Possible uses – inside your plant – for: | Food, pharmaceutical and drink industries also use non stick in engineered parts and other surfaces like: |

|---|---|

|

|

Wear resistance is generally improved with Galling resistance.

Comparison of deposition methods | ||||

| In-situ Cascade e-Ion | Nano-10 microns | Oxynitrides Nitrides Ti (C,O,N) Enhanced SiC and Ti(C,N,O) Si3N4 and variations | Galling and Wear Extreme Resistance Non Stick Corrosion Resistant Bearings and Anti Seize Anti friction Biomedical Cell Phones | Machine Tools Cast Iron Die Steel Stainless Steel Graphite Glass |

| De-e-Ion Deposition | Nano-Microns- mm depends on objective. Cascade e-Ion assisted rapid deposition. | Alumina Molysilicides Carbides Diamond Coatings Composites | Anti microbial Dense and Hard Overlay Friction | Metals Polymers Ceramics |

| PVD | 1 – 5 μm (40 – 200 μin) | Ti (C,N) | Wear resistance | Machine tools |

| CVD | 1 – 50 μm (40 – 200 μin) | Sic | Wear resistance | Fiber coatings |

| Baked polymers | 1 – 10 μm (40 – 400 μin) | Polymers | Corrosion resistance, aesthetics | Automobile |

| Thermal spray | 0.04 – 3 mm (0.0015 – 0.12 in) | Ceramics and metallic alloys | Wear resistance, corrosion resistance | Bearings |

| Hard chromium plate | 10 – 100 μm (40 – 200 μin) | Chrome | Wear resistance | Rolls |

| Weld overlay | 0.5 – 5 mm (0.02 – 0.2 in) | Steel, stellite | Wear resistance | Valves |

| Galvanize | 1 – 5 μm (40 – 200 μin) | Zinc | Corrosion resistance | Steel sheet |

| Braze overlay | 10 – 100 μm (400 – 4000 μin) | Ni – Cr – B – Si alloys | Very hard, dense surface | Shafts |

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA