Tube Furnace-Horizontal

Tube Furnace Features

Single Zone and Multi-Zone Furnaces

(Single or Multitube)

Models with continuous operating temperatures of up to 1760°C and maximum operating temperatures of 1800°C.

Fully programmable control panels allow for high accuracy and control of processes or applications.

Configurable for numerous applications.

Small footprint. MHI tube furnaces can fit on top of a workbench.

Durable stainless steel construction.

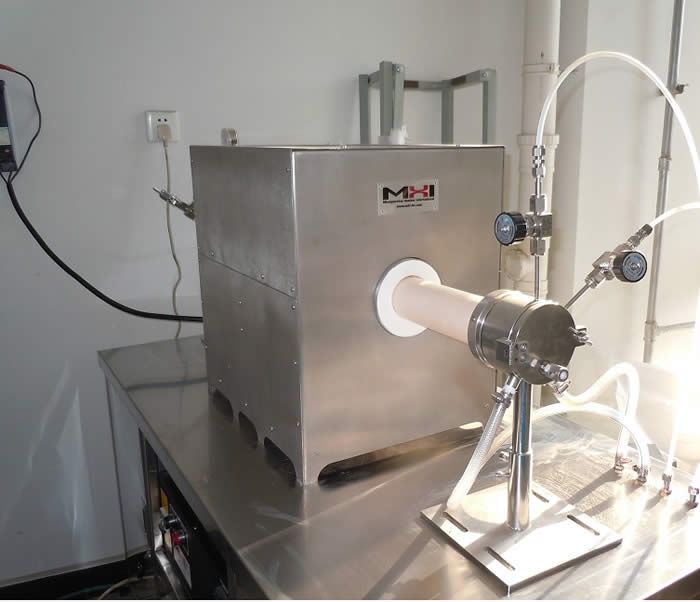

End caps allow accurate temperature and atmosphere control. The vacuum depends on the temperature and type of process tube chosen 10^-5 torr.

Compatible with MHI-DACS Software for data logging and process programming.

SIMGAS gas mixing system allows for precise mixtures at moderate flow rates.

Quick disconnect end caps allow for easier configuration changes.

Tube Furnace Models

All MHI tube furnaces feature rugged stainless steel construction, electronic control capabilities, and MHI’s highly acclaimed heating elements. Our tube furnaces feature continuous operating temperatures of up to 1760°C. Use for air or combustible gases.

| Single Zone Horizontal Tube Furnace Models | ||

| Model Number | Temperature | Heated Tube Dimensions |

| H14HT | 1400°C (2552°F Max) | 2.5″D x 12″L |

| H18-40HT | Up to 1760°C (1800°C/3272°F Max) | 2.5″D x 12″L |

| 3H18-40HT (2.5 or 4″) x 27 | 1760°C | (2.5″ or 4″)D x 27″L |

| Split Furnace Vertical or Horizontal | ||

| Model Number | Temperature | Heated Tube Dimensions |

(Vertical) | 1400°C (2552°F Max) | 3″ D x 8″ L |

Large Industrial-scale Horizontal Tube Furnace

Large Volume Single Zone

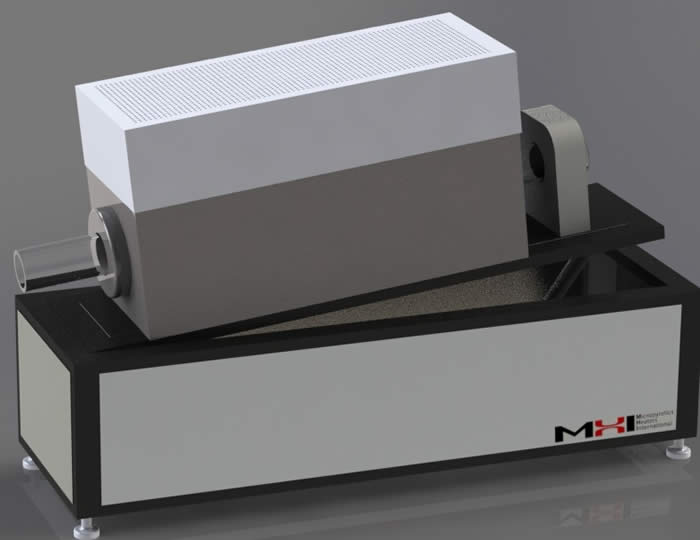

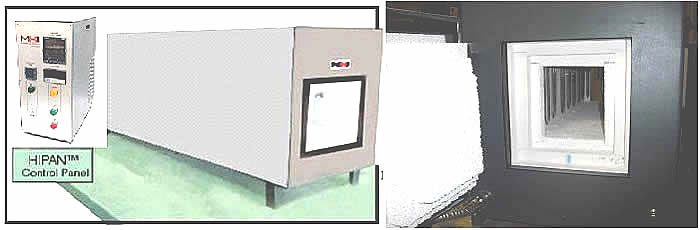

New Tilt and Rotate Single and Multi-Zone Tube Furnaces (please click on the picture below)

| Single Zone | Three Zone | A look inside |

|  |  |

| Model Number | Temperature | Tube Dimensions in inches for Hot Zone | Process Tube |

| 575H14-HT | 1400°C | 4″D x 16-17″L | Metallic for 1250°C and below or Ceramic for above 1250°C use |

| 575H11-17HT | 1700°C | 5.75″ D x 14″L | Ceramic |

Tube Furnace Applications

Because of their versatility, MHI’s furnaces allow for several uses.

Because each application is unique, Please Contact MHI to discuss which product best fits your needs.

Tube Furnace Common Uses. MHI offers complete gas management systems, from palladium refining to dross separation techniques for aluminum. | |

| Nano-Diamond l Production Gas (%CO2 ~0.4%, %H2O~ 0.5 to 0.9, %CO~20.5 to 20, %N2 ~42, H2~36 %, CH4- call) http://waveguide/wastes/nonhaz/industrial/special/mining/minedock/id/id4-pla.pdf | Reaction Furnaces Recycle Commodity Noble Metals For Palladium and Platinum Production. Recycle from the dross/cake sponge. |

| Attach to the steam generator (end caps required). | Attach to gas input (end caps required). Use SIMGAS. |

| Measure spectral intensities, emission and absorption, and line broadening with temperature for Microwave to Terahertz Radiation | See information on general furnaces. |

| They are drying, Brazing, Vacuum, and Inert. Save substantially. Contact MHI for a per-load ROI estimator and methods to do quick loads. | Gas Processing |

| Melting | Sintering, Oxidation, Pervoskites. Add OAB steam. |

| Industrial Processes for Energy, including Thermal Membranes | Tempering, Austempering, and Martempering without large graphite furnaces (the new modern way) |

| Gas Preheating, Hydrogen Gas Heating. | Annealing, Coloring, Heat treatment. |

| Materials Testing, Creep, Fatigue, High-Temperature Wear. Lubrication. | Metallurgy. Use for palladium refining to dross separation techniques for aluminum. |

| General Heat Treatment. | Custom Applications. |

| Industrial Processes for Syngas, Biomass, Biogas, H2, CO2 for H2 supply, electricity generation, CHP-sawdust, paper waste, and switchgrass. | Gas Processing, Hydrogen Pyrolysis, Cellulosic Biomass to Hydrogen Pyrolysis, Gasifier, Ag-forest residues, Wood chips, Sawdust, Paper Waste, Energy Crops – switchgrass, miscanthus, or biomass crops. Even with 40-55% moisture, the process gasifies cellulose, hemicellulose, and lignins. |

Furnace Controls

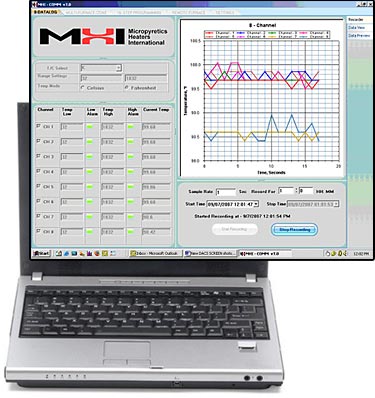

MHI offers three control options with our tube furnaces: Electronic control panels with overtemperature controls, MHI DACS as an electronic controls program, and SIMGAS4 as a gas management system. The combination of these controls makes MHI tube furnaces highly robust and scalable.

| MHI Furnace Controls | |

| Many of MHI’s electronic furnace controllers feature multiple voltage inputs, overtemperature controls, programmable cycles, and several other features. For more information about MHI’s control panels, Contact Us or See More Information. |  |

| MHI Data Acquisition and Control Software (MHI DACS) | |

| MHI Tube Furnaces are compatible with MHI DACS for furnace controls, step programming, data logging, and more. DACS also allows for remote furnace control, allowing one central location to control multiple devices. |  MHI DACS Software |

| MHI SIMGAS4 Gas Mixing System | |

| Gas Management Systems in tube furnaces serve the materials and electronic community when processing has to be carried out in vacuum or gas atmospheres. You can expect excellent temperature uniformity with MHI tube furnaces. We can also provide you with a complete custom gas control panel with gas lines and controls. |  SIMGAS4 and Rotary Tube Furnace |

Single Zone Tube Furnace

| General Information | ||

Horizontal Tube Furnace |  Multi Tube Furnaces | Tube Furnace with Controls |

| MHI’s single-zone tube furnaces are available in temperatures up to 1760°C. The standard dimensions for the heated area are 2.5″ x 12″. Single-zone furnaces are highly uniform. | ||

| Single Zone Horizontal Tube Furnace Models | ||

| Model Number | Temperature | Heated Tube Dimensions |

| H14HT | 1400°C (2552°F Max) | 2.5″D x 12″L |

| H18-40HT | Up to 1760°C (1800°C/3272°F Max) | 2.5″D x 12″L |

| HT Models with long single zones up to 27″ zone | Up to 1760°C (various Models with TRIPAN) | 2.5″D x 27″L |

Multi-Zone Tube Furnace

| General Information | |

| Three Zone Tube Furnaces include HIPAN controllers with a Master/Slave option. Each controller is equipped with independent over-temperature control. Three-zone furnaces feature temperatures up to 1760°C and heated tube lengths 27″. Multi-zone furnaces feature high uniformity due to their design and the use of multiple BPAN/XPAN controllers. |  |

| Multi-Zone furnaces feature excellent uniformity throughout the heated tube and handy controls allowing precise step programming. |   Rotary Tube Furnace with Controls and SIMGAS4 |

Tunnel Furnaces up to 1380°C or 1700°C Unlike the strictly sealed tube furnaces above, tunnel furnaces can hold only light vacuum but can be used with flowing gas or steam. Three Zone or Single Zone availability Single phase or three phase – please specify wall power availability |  |

| 3-Zone Horizontal Tube Furnace Models | ||

| Model Number | Temperature | Heated Tube Dimensions |

| 3H14HT2.5×27 | 1400°C (2552°F Max) | 2.5″D x 27″L |

| 3H18-40HT2.5×27 | Up to 1760°C (1800°C/3272°F Max) | 2.5″D x 27″L |

Large Volume Single Zone Tube

| Model Number | Temperature | Tube Dimensions in inches for Hot Zone | Process Tube |

| 575H-14HT | 1400°C | 6″ D x 14″L | Metallic for 1250°C and below use or Ceramic for above 1250°C use |

| 575H11-17HT | 1700°C | 6″ D x 14″L | Ceramic |

Heater control panel

BPAN-O-PLUS

Also, see the customer page for use

Large Industrial-scale Horizontal Tube Furnace

Large Volume Single Zone

Tube Furnace Applications

Because of their versatility, MHI’s furnaces allow for several uses.

Because each application is unique, Please Contact MHI to discuss which product best fits your needs.

MHI high temperature furnaces incorporate industry tested control systems. Tube furnaces find use where an accurate temperature or temperature gradient is required with an atmosphere. Tube furnace applications. Several models are listed below. Typical options that are routinely quoted are the gas management systems (SIMGAS), oxygen and other gas sensors, vacuum and vacuum measurement systems. Use for sintering, brazing, metals, ceramics, optoelectronics, biomaterials, composites and intermetallics.

MHI’s single and multi-zone tube furnaces are available in temperatures up to 1760°C for all applications where process heat is required. Standard dimensions for single phase heated tube zone of 2.5″ x 12″ three zone high uniformity are 27″. Several laboratory and industrial models available with quick disconnects. Long uniform zone. A typical configuration is shown on the right with multiple gas inlets. Available also are customized end-caps or quick-disconnects (snap screw or buckle snap). Everything is listed in the quote for choosing options including a low price data acquisition and process download option. How uniform are the MHI tube furnaces? A testimonial from the Stanford HUTF facilities. See also uniformity page. “The high-uniformity tube furnace facility provides the ideal environment for quantitative measurements of absorption spectra and spectral parameters (line strength, line-broadening coefficients,and more). It is also provides controlled conditions for sensor validations“.