Description

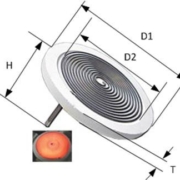

MHI GAXP Spiral Microheater 1400°C (OD=2″) MC-GAXP-130

Approximately 700 Watts [26V @ 27A (RMS)]Ceramic Base Included

** Power reported under free radiating/ no-load condition with heater resting on provided ceramic plate. Horizontal use only – do not invert. Ceramic base included with the MC-GAXP-130. Note: the one and two inch microheaters do not have a ceramic recess. Picture shown is generic.

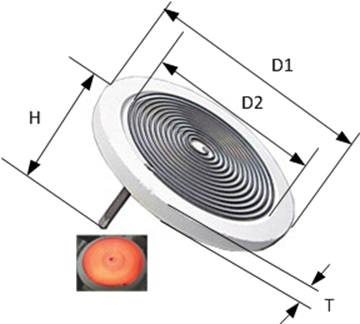

D1 and D2 are separated by 0.1″ T is 0.25″ and H is 2.5″. D1 is the OD.

Connectors comprise of One set of appropriately rated connecting clips.

Alumina ceramic is rated to 1800C.

Note that the maximum current/power will be different (lower) when the unit is covered. Please do not exceed limits of current, voltage or element temperature.

For more information please visit our GAXP Spiral Microheaters page

For more information on the BPAN-O-PLUS controller please click to the Power and Temperature Control Panel Pages.

For controls choose either

Feedback controls namely BPAN-O-PLUS-120T and Transformer

For customers who do not have a 120V wall supply, a 220V to 120V transformer will be added at no extra cost.

or

Open Controls with no feedback i.e. the DC Power Supply and a TC Read. Choose also the T/C and Extension Wire Option.

No transformer is required if the DC power supply is chosen.

Please choose BPAN-O-PLUS-220 when more than 3 units of the 2″ Spirals are placed in series

Only the BPAN-O-PLUS 120T (120V) option should be chosen when a single 2″ unit is used.

Alumina ceramic is rated to 1800°C.

Connecting wires should be rated for current e.g. 10 AWG

When checking out, the weight will be calculated with the control panel option.

The correct weight and shipping price will be shown in the final acknowledgement from MHI.

Note that the maximum temperature is at the center of the spiral region unless asymmetric power delivery is required

In the diagram in the specifications tab D1 and D2 are separated by 0.1″ T is 0.25″ and H is 2.5″. D1 is the OD.

For obtaining maximum temperature MHI controls are highly recommended. Large diameter GAXP® microheaters could develop some springiness from induced magnetic forces. Potting in ceramic paste is allowed as long as care is taken to factor-in the loss of any thermocouple response in the measured temperature. Note element temperature will be higher and maximum element temperature should not be exceeded. In the free radiation mode the power can be maximized.

The objective of the use for free radiating devices is to maximize the radiative POWER transfer from the heating elements. If the heating element is covered with insulation, the objective of the user changes to obtain a certain temperature inside the insulated region. The control of temperature inside a chamber, or power maximization in a free radiating mode can be made with MHI temperature and/or power controllers. When covered the power and current will be lower and the element temperature can be exceeded quickly if not monitored and controlled. For either objective, one cannot exceed the rated temperature or maximum current of the heating element. Power output will be lower in enclosed radiation mode with a temperature control feature as opposed to or in addition to the power control.

MHI Microheaters

National Laboratory, USA

I have received the heater and control system, and it is all visually undamaged and exactly to my specifications. Thank you for your help!

Professor V.V. USA Surface Science Center, Ohio

discovery with the Cascade e-Ion Plasma is indeed very exciting and the potential for all sorts of applications is enormous.

C. N., USA

“Thanks very much for the quick and complete answers!”

Researcher at US National Laboratory

“MHI offers Microheaters that no other manufacturer can compare to.”

Senior Professor at Premier World University

“We have used the heater, it is working well. Do you have calibration chart (Temperature v/s Voltage) for this MC170 microheater. ……………..Since we do not have temperature measuring tool for such a high temperature (1900C)…………..We are planing to order one more heater………………….”

Senior Professor at United States Major Big 10 University

MHI ……. the only heating elements that work well for us in these studies; when we publish our results — I will be sure to send you the reference, I see your on your website that you link to work utilizing MHI products.

Product: THM and Robust Radiator..

Professor A. R., Academician, Ukraine

Several years ago we have bought in your company the front loading M18-40 furnace and two robust radiators and got much satisfaction working with them. Now, we believe, it is a very time to substitute heating elements in the furnace and to buy new radiators.

Product: RR and Furnace

B.K., Ohio Energy Efficiency Center

“I wanted to let you know that we were able to connect the heaters successfully with the help of your video. …The heaters are heating up like they should as far as we can tell…… ”

F.G., France

“We have received the Ultra Coil… the piece seems very nice once again. Thank you.”

P.M., Australia

“…the equipment arrived very quickly and in good order.”

Y.X. Canada

“Thank you for your email. We tested the microheater last week. It worked well…”

R. Sweden

“…I always give you my best recommendation for the prompt service and customer minded attitude…”

M.L., USA Government

“….. the customer service to date has been exceptional. Calls and e-mails are returned promptly, and your customers are well taken care of. We will definitely work with MHI again in the future.”

S.W. National Laboratory (Energy), USA Government

“….. , I just received the PH-G4-3.5 I ordered and it looks great. …..we’d like to purchase a controller for it as well.”

K.R., Sweden

“The heater looks great, and in tact so far!”……..“We received the ceramic holder today. Thank you very much. We appreciate your spontaneous enabling help I hope we can try the heater soon.”

Dr. M (United Kingdom)

…..”This should get me right back on track with this project – which has gone very well thanks to your assistance”.

Silicon Valley Customer

“Everything is great! I’ve inspected the elements and roof refractory and everything is in great condition”.

Start up US Company Supported by MHI Technology

“We plan on continuing our relationship with MHI to further develop and sustain a robust localized heat treat capacity”.

MHI In. USA

MHI In. USA MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA