Many abrasive wheels can be reconditioned by exposure to the clean plume. Please ask for a case study or send us your wheel for free reconditioning trial. Hardfacing is feasible for small to very large surfaces that are used for boring and grinding. Please contact MHI for feasibility assessment.

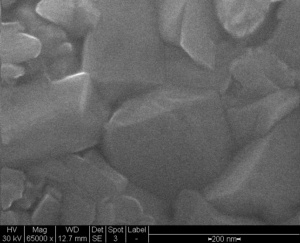

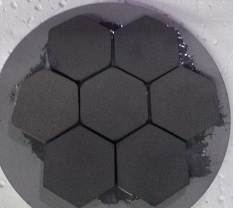

If you already own a Cascade e-Ion machine. Immerse part that needs surface conditioning into the CleanElectricFlame™ and remove quickly from flame within seconds depending on size. Please contact MHI for process advice. The picture above shows how the part is held in the CleanElectricFlame™. Air was used in the Cascade e-Ion Plasma™ generator which then ionized and quickly formed a hard shiny abrasive surface. Used for grinding hard ceramics.

Flexibility of Operation. Do one part or many parts. Follow as -required, turn-on and shut down and idle parameters. Avoid traditional processing-time of days. No vacuum requirement. Part manipulators can be robots to belt machines or combinations. Your choice. Repair abrasive thread mills for long holes.

Please call MHI for boron nitride and diamond resurfacing.

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA