What Are Shrink Film and Textile Materials Made of?

There are several main types of shrink films. These include:

- PTFE (Fluoropolymer) have a wide operating temperature range (-55 to 175°C), a low coefficient of friction, and high resistance to chemicals and punctures. The closely related PVDF (Polyvinylidene Fluoride) materials are intended for high temperature applications.

- PP (Polypropylene) is a tough, general-purpose film that shrinks at relatively low temperatures but represents somewhat older technology as regards to shrinkage amount and other factors. Polyolefin is the most common kind. They are flexible and fast-shrinking, and manufactured in a wide range of colors (including clear). Some Polyolefin is recorded to be FDA approved for food packaging.

- PE (Polyethylene) is a good low cost material for bundling (combo unit). Closely related are PET or PETE (Polyethylene Terephthalate). PET is commonly used for soft drink & water bottles, cooking oil bottles, peanut butter containers. It is the most widely recycled plastic. Also closely related is HDPE (High-Density Polyethylene). HDPE is slightly waxy and semi-rigid. It does not crack. It floats on water.

- PVC (Polyvinyl chloride) shrink film is extremely strong and clear and generally used for the hardest applications.

- Many vendors can supply you printed or bare shrinkage film in flat, cylindrical or any other shape you may have interest in. PVC tubes are available in several colors and can be used outdoors. MHI can help you contact expert shrink wrap materials and label manufacturers. for cpg, pharma,melting polymers/sugar, conditioning food, surfaces, textile, shrink label and modifying unique alloy surfaces with high temperature pure steam and hybrids.

- Common Problems with Standard Hot Air and Pressure Boiler Steam

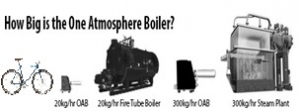

Doing your own shrinkage wrap or labeling has never been easier or more cost effective. Moving your one atmosphere boiler from station to station is fully possible.

OAB® pure steam now offers about 90% savings in energy and water over conventional boilers. With the availability of the powerful OAB® steam, label designers can now offer shape and seal features simultaneously.

Call MHI for information on textile fibers.

Want to find out how MHI can help you meet your steam needs? Fill out a quick questioner and we will help find a solution to meet your needs.