What is Cascade e-Ion Plasma?

Is MHI’s Stable Cascade E-ion a new type of flame with only air/electricity inputs?

Richard Feynman* implied that real discovery was like finding a new type of flame.

About the Cascade e-Ion Technology

Glass Bending, Optical Data Transfer, Biomedical Coating/ Deburr, Tool-bit Reconditioning, Abrasive Wheel, Cast-Iron, Stick Resistant Steel Surfaces, Anti-Seize Treatment for steel bearings, Bolts and bushing, Request Information

Compare with lasers, electron beams, and nitriding machines.

The Cascade e-Ion technology is a Stable Thermal Cascade Plasma Generator called the CleanElectricFlame®. The breakthrough process produces a high-watt density atmospheric pressure-level plasma plume capable of rapidly cleaning, deburring, depositing, growing, hardening, joining, reacting gaseous to metallic materials, and many more applications, like rapid brazing, rapid heat treatment, and ultra-low total energy degradation cost.

Customer Testimonial: “I had a look at your table comparing the cost and various features of (standard RF) plasma nitriding and MHI (Cascade) e-ion plasma nitriding machines, and the advantages of the latter are remarkable. This type of comparison… an alluring proposition for any stakeholder to purchase such equipment.”

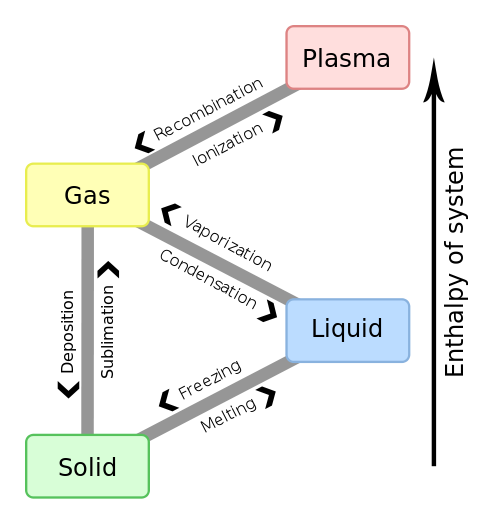

Cascade e-Ion Plasma™ technology uses electricity and air (or any other gas) to produce a CleanElectricFlame® plume containing ions, electrons, radiation, and hot gas. It is a versatile tool for several possible applications. This is the only plasma generator that offers close to 100% power transfer, thus making it a unique, highly efficient, directed energy source. Applications could include forming a single layer of atoms (or stacks) with far-reaching potential. Known as two-dimensional materials, this class has grown within the past few years to include lattice-like layers of carbon (graphene), boron (borophene), hexagonal boron nitride (white graphene), silicon (silicene), phosphorous (phosphorene) and 2d oxycarbonitrides or unique carbon-nitrogen compounds—Cascade e-Ion applications page.

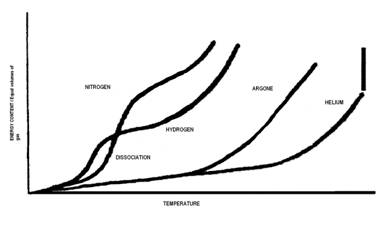

On account of the number of ions that are quickly supplied to a part, the Cascade e-Ion plasma™ finds uses in machine-tool development of new and reconditioning machine tools, non-stick surfaces, clean glass bending, covers for liquid metals, plastics (polymerization and functionalization), metals (heat treatment of semiconductors, metal fBelowano-deposition and brazing and related operations). The machines are also used in ceramics (ceramic surface modification, nano-treatment, and other modern materials from new process type use). Please click through to our Cascade e-Ion applications page for typical solutions. The first ionization energy of gases is shown below as a function of the atomic number. When used for surface treating, XPS and other electronic probes display the fine (nano or surface quantum dot) structure, depth of ionic penetration, and many undiscovered new phase formations that may be used advantageously for applications.

Pictures of wide-area plasma | Videos of wide-area plasma | ||