Energy Savings, Environmental Benefit and

Increased Productivity with the DRO Cascade e-Ion Source for Aluminum Smelting.

Introduction

Over the years, the aluminum casting industry has been searching for an energy efficient rapid melting device with reduced losses from oxidation and contamination. To accomplish these goals, along with energy efficiency, the furnace design must incorporate heating systems, which allow directing highly concentrated heat on the aluminum ingots, sprues, or scrap in order to provide rapid and efficient melting. Alternately a retrofit is required for existing aluminum furnaces which may assist with the rapidity and associated energy saving. Only recently, a new mid temperature range (1200K-1600 K) convective plasma device has been patented, and has become available commercially known as the Cascade e-ion® shown in figure 1.

Non-plasma convective heating is used in materials processing industry for heat treatment and melting applications. Plasma enhancement has often been attempted. The research in industrial applications of Plasma has largely been concentrated on two types of systems, viz., thermal plasma at atmospheric or near atmospheric pressures and low-pressure plasmas. Thermal plasmas are used extensively in applications such as plasma spray coatings and arc welding. Typical temperature in such applications may be in the range of 5000-15000K and pressure is atmospheric. In the second case, plasmas at low pressures are used for applications such as chemical vapor deposition and polymer processing. These are generally cold plasmas as due to low collision coupling between electrons and heavy particles, the temperature of ions and neutral remains at room temperature. Thermal plasmas have also received much attention in the literature. However, these two extremes (very hot plasmas at atmospheric pressure or cold plasmas at low pressures) are not best suited for metallurgical work. For example, most of the aluminum melting or steel heat treatment is carried out between 600oC and 1200oC. The low pressure plasma possesses very low energy density and can not be used for aluminum melting. The very high temperature thermal plasmas result in significant heat losses and may result in poor efficiencies. The one atmosphere patented plasma generator discussed in this article is able to address both these needs. The device converts air into a low ionized plasma at one atmosphere. The resulting plasma at about 12000C is able to provide a nitrogen cover to the metal (eliminates cover gas) as well as able to provide focused energy and vastly improved heat transfer both leading to significant energy efficiency benefits.

A typical device that can easily be attached to any existing furnace is shown in figures 1a and 1b. The device as shown in Figure 1c, operates with a fan and produces the required amount of plasma directly from the air. Unlike conventional plasma guns, the flow of plasma is gentle and extremely quiet.

Figure 1. A picture of a typical 10kW Cascade e-ion, Ionic Source Generator. The overall length is about 25 inches. The diameter is 7 inches. Schematic configuration |  Aluminum Melting Overview |

- Reduced Energy Costs – Energy efficiencies of 0.2kWhr/lb for melting with no emissions.

- Improved melting because of ultra clean metal.

- Clean melting, with dross values less than 0.5% depending on configuration.

- No requirement for nitrogen, argon, or chemical fluxes – significantly reducing operating costs and the environmental impact.

- Extremely small equipment footprint as shown above in Figure 1.

- Quiet operation – Zero noise -much lower than typical, conventional plasma systems.

- High energy density nearly four times compared to the standard

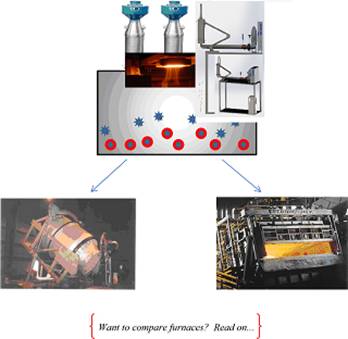

Although the main method of use is to add the Cascade e-Ion to an existing furnace in a retroactive manner it can also be used as the only heat source in a new furnace. Such a furnace (a typical design is shown in Figure 2) is a possible method to deal with the next generation melting problems, allowing energy rates as low as 0.198 kWh/lb, as opposed to induction melting energy rates of 0.345 kWh/lb. The PAM can be constructed as shown an automated furnace which allows quick charging, rapid melting, pouring, and disposal of dross. The combined effects of conduction from the hearth, forced convection from plasma, and radiation, contribute to the concentration of heat. Such a furnace may be constructed for a variety of melting needs, ranging from ingot melting, sprue melting and scrap melting for recycling. Several custom footprints are possible. In addition, there is no noise or foul burning gas smell. Table 1 below shows typical melting parameters observed for a 23KW system.

Figure 2. A furnace chamber with continuous loading and unloading can be constructed with the Plasma Airtorch® as the only heat source. A cut-away from such a furnace is shown.

Table 1: Typical melting results from a 23kW melting furnace. The furnace had a footprint of about 36 square inches.

| For Aluminum a 23kW system yields: | |

| Energy to melt | 0.2kWhr /lb |

| Dross/Total Metal Loss | ~0.5% or lower depending on alloy |

| Melt Rate | ~12.7 g/s (compare with 3g/s for conventional) ~1 Ton / day for 23kW. |

| Energy Concentration | 269,146 BTU/ft3 (~107kJ/m3) |

Energy Density

Conventional aluminum furnaces generally do not focus on energy density as this the numbers are low for wire-wound, gas fired and silicon carbide powered aluminum furnaces. However high energy densities of the furnace allow more heat to be transferred to the charge and less heat to the outside and a furnace with high energy density is desirable. Thus energy density is important for energy conservation as well as for reducing the foot print of the furnace. A typical electric resistance melting furnace exhibits an energy density concentration of 64,557 BTU/ft3 as opposed to the new PAM with 269,146 BTU/ft3, for equal volume of hot zones. The PAMF has four times higher energy per unit volume compared to electric resistance furnace, thus making it a unique furnace with highly concentrated power.

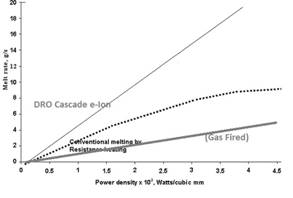

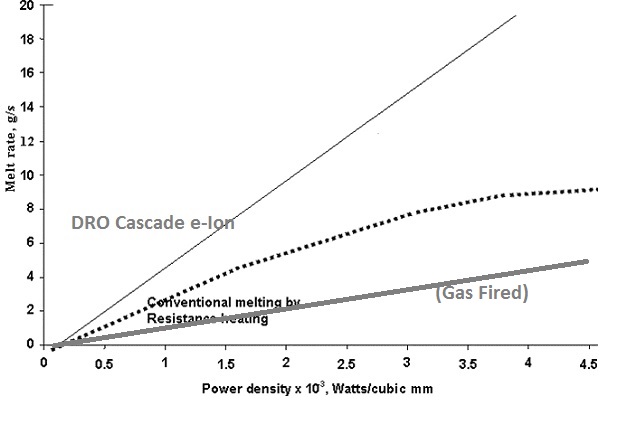

In addition, as the power density (i.e. energy density per unit time) is increased in conventional furnaces the melt rate tapers-off as shown in figure 3. In contrast furnaces which have a Plasma Airtorch® the melt rate remains high because of the enhanced heat transfer that the plasma provides

Figure 3. Conventional furnaces are unable to create heat on the charge and their efficiency falls off. Plasma assisted furnaces automatically have high power densities and heat transfers directly to the part.

Why does this happen? The reason lies in the fact that the heat transfer coefficient increases with the gentle plasma even where the convection velocity is small. Figure 4 below shows the basic plasma heating and nitrogen cover principle. Figure 5 is a plot which shows the enhancement in the surface heat transfer coefficient to the charge.

Figure 4. The basics of plasma heating. Note significant improvement in heating rate. Please contact MHI for details.

Figure 5. Variation of heat transfer coefficient with the degree of ionization for aluminum. A similar result is expected for all metals.

Economic Comparisons

For economic comparisons between the several techniques used for aluminum melting, the factors to be taken into account are: (1) The cost of equipment and installation and (2) the operating costs, which depend on (a) the utility costs in the area (b) the energy efficiency of the equipment chosen (c) the quality requirements of the finished casting (d) the metal losses (dross) to be expected as a result of the melting process. In additions there is a cost associated with (i)Regulation and comfort factors, such as EPA considerations, heat, noise, and air pollution and (ii) The casting size range and the weight of metal required per day and associated storage and manpower costs.

Installation costs of electric resistance and fossil-fuel-fired furnaces are comparable. It is not practical to hypothesize a specific example, as there are too many possibilities to take into account. In general, fossil-fuel-fired furnaces require fluing, blower equipment, and in some cases heat exchangers (for preheating combustion fuels); however, on balance, power controls often result in a slightly higher investment for electric operations. Another widely used method for melting is the induction furnace. While induction furnaces cost more than resistance furnaces their production rates are generally much higher. An operating cost comparison is presented the table below, to illustrate the relative expenses for a hypothetical aluminum melting operation. Metal loss includes dross plus flue loss. The most significant operating cost consideration is not only in the relative cost of the utilities, i.e., gas, oil, electric, etc., but the relative metal losses to be expected and the reliability index. Electric resistance melting yields are high, while metal losses from fossil-fuel operations may be as high as 8 percent. When taking into account the metal loss, the current as well as the projected metal cost at the spout should be used in making investment plans. Utility costs vary widely in different localities. For example, gas prices can range from $2.50 to $4.86 per MCF, while electric costs can range from $0.032/kWhr at off-peak times to $0.08/kWhr or more. Theoretical melting for aluminum is 445BTU/lb. Efficiency is calculated as in the table below where mass is the melted mass:

———– (1)

———– (1)

| A summary of the qualities of most conventional and the new Plasma Aluminum Melt furnaces:� |

[table id=3 responsive=”collapse” /]

CONCLUSION

Based on the results obtained to date, the following energy and environmental benefits are noted from using the Cascade e-Ion for aluminum processing.

Measured Energy Saving

The improvement in energy efficiency is noted when using the Cacscade e-Ion

Environmental (waste stream) savings

In addition to this elimination of harmful emissions and noise (no noise) and increase of productivity. Since gas/oil burners are replaced by the ionization units.

Productivity and Profitability

A small foot print furnace or a retrofit to an existing furnace is able to considerably enhance the melt rate (four times) and eliminate labor time with disposing waste.

Benefits of DRO Cascade Assisted Aluminum Melting Furnaces

A case study was made for EMTEC. Here the Cascade e-ion was also used for melting as well as as dross reduction. The standard configuration however is with the cascade e-ion as an add on cover. Summary: Highest melting rate and low dross was achieved in the report. Best energy efficiency and best furnace loading

The aluminum industry is one of the most energy intensive industries in the world. Compared with other competing materials such as steel, copper, wood, glass, and plastics, etc., aluminum has the highest energy content. The availability for the optimum furnaces for clean-aluminum melting/casting and heat-treating will certainly improve the competitive position of aluminum vs. other materials. Any DRO Cascade e-Ion Aluminum Furnace could bring several immediate benefits to the vast aluminum industry.

Reduced energy consumption will be the number one payoff. U.S. primary aluminum production was about 3.6 million tons while secondary aluminum recovery was about 3.3 million tons. The average energy consumption for producing primary aluminum is about 16,500 kWh/ton, in which 5.5% (~908 kWh/ton) is consumed for melting/casting. On the other hand, the average energy consumption for producing secondary aluminum is about 6% of that required for primary aluminum. The total energy consumed for melting/casting aluminum (both primary and secondary) in the U. S. per year is thus approximately (3.6 x 106 tons x 908 kWh/ton + 3.3 x 106 tons x 990 kWh/ton) = 6.5 x 109kWh (22.3 x 1012 Btu).

No need for nitrogen cover

A key benefit of using the cascade e-Ion ionic source comes from the elimination of nitrogen, argon, or toxic flux covers normally used for melting and holding aluminum. The DRO machine takes air and converts it to a nitrogen-ion cover.

Small foot-print and no noise

High melting rates are thus achieved with a low footprint of the furnace. Noise and toxic materials normally used as fluxes are eliminated (except that from a blower).

Summary results

The DRO Cascade e-ion is a ~ 10kW device. In most instances, the melting furnace power overpowers this and so the DRO is not primary for melting. However, for smaller furnaces, an experiment was conducted that showed that DRO melting gives significant energy efficiency.

Over the years, the aluminum casting industry has been looking for a clean energy-efficient rapid melting furnace with reduced losses from oxidation and contamination. To accomplish these goals combined with energy efficiency, the furnace design must incorporate heating systems, which allow directing highly concentrated heat on the aluminum ingots, sprues, or scrap. The Plasma Aluminum Melting(PAM) furnace is the answer to deal with the next generation melting problems, allowing energy rates as low as 0.198 kWh/lb, as opposed to induction melting energy rates of 0.345 kWh/lb. The PAM is an automated furnace that allows quick charging, rapid melting, pouring, and disposal of dross. Combined effects of conduction from the hearth, forced convection from Plasma, and radiation contributes to the concentrated heat source. This furnace is developed for a variety of melting needs ranging from ingot melting, sprue melting, and scrap melting for recycling. Several custom footprints are available. There is no such furnace available elsewhere for aluminum melting. In addition, there is no noise or foul burning gas smell.

For Aluminum a 23KW system yields: | |

| Energy to melt | 0.2kWhr /lb |

| Dross/Total Metal Loss | ~0.5% |

| Melt Rate | ~12.7 g/s (compare with 3g/s for conventional) ~1 Ton / day |

See below for a more detailed table.

Ingot, sprue and scrap melting

The furnace above was experimentally constructed to allow quick charging of ingots, sprues, and scrap for melting and pouring into the holding furnace or to ladles for casting parts.

1. The plasma provides a clean and oxidation-free atmosphere.

2. Energy efficient, as low as 0.198 kWh/lb, as opposed to the industry’s clean and best energy efficient rate provided by the induction melting practice at 0.345 kWh/lb.

3. No capital investment for creating an induction melting facility. Induction melting of aluminum is only 50-70% efficient. Compare to over 95% efficiency.

4. Increased productivity is realized with increased rates of ingots or sprue loading into the furnace.

5. Direct utilization of clean molten alloy for die casting, permanent mold, or sand molds.

6. The key to success lies with the ability to reduce the residence time of the sprue to prevent the dissolution of the filter material.

7. Inexpensive, since no need to add expensive pure aluminum to dilute iron content, unlike the current industrial practice.

How does the energy density values of PAM furnace compare with conventional furnaces?

Does your conventional furnace manufacturer even talk about energy density? A typical electric resistance melting furnace will have an energy density concentration of 64,557 BTU/ft3 as opposed to the new PAM with 269,146 BTU/ft3, for an equal volume of hot zones. The PAMF has 4 times higher energy per unit volume compared to an electric resistance furnace, thus making it a unique furnace with highly concentrated power.

How does the quality of melt compare with conventional furnaces?

1. Although, induction melting furnaces offer somewhat a rapid melting, because of their intense stirring activity, breaks the oxide film from the molten alloy surface and promotes a severe oxidation process leading to the generation of more dross and dross dispersed melt. As the density difference between the molten alloy and that of dross is not significantly different, further deteriorates the quality of the cast material resulting in poor ductility, and poor electrical conductivity.

2. Gas or oil-fired furnaces invariably produce nascent hydrogen from their combustion processes, providing an opportunity for excessive dissolution of the gas leading to hydrogen embrittlement and poor fracture toughness values. To remove the dissolved gases, an additional step of de-gasification of molten metal must be employed which will incur further expenses due to chemicals, tools, waste of energy, and labor.

3. The conventional electric sprue melting furnace will melt all pieces of sprues and remain in molten condition for a long time until it attains sufficient superheat to facilitate de-gasification treatment. During this long waiting period of time, the material of the filter will have ample opportunity to dissolve in the melt, resulting in iron-rich aluminum. Large quantities of expensive virgin aluminum ingots will be needed to dilute the iron, thus making it a prohibitively costly process.

4. The PAM furnace melts at an extremely rapid rate of 13 g/s and allows the molten alloy to drain out quickly leaving the steel filter material behind. Further, the convective plasma provides a protective atmosphere while keeping the thin protective oxide film on the molten surface intact, without causing it to break, preventing the formation of dross in the absence of turbulence or agitation. Molten aluminum surrounds itself completely with a thin envelope of the oxide film. As long as this oxide layer remains unbroken, the rate at which gas is absorbed by the melt is quite low, and further oxidation is retarded.

5. The dross generated by the PAM is insignificantly low, typically less than 1%, unparalleled to any known industrial melting practice.

6. Alloy chemistry adjustment is not frequently required using PAM or smooth melt surface furnaces since the volatile elements such as Li, Mg, and Zn will not vaporize due to rapid melting, smaller residence time, quick pouring, and faster disposal of filter materials.

Often a question is asked whether DRO machines should be used like an Intense Plasma Melter for scrap and spent dross.

DRO-PAM type furnaces were conceived as continuous melters but the aluminum industry has not really caught on to continuous melting operations. Conventional high-powered plasma furnaces are costly and may not be required. Use a low-power DRO and an Airtorch instead.

Melting old spent dross mixed with something like aluminum chip-waste – such recovery methods include melting at a very high temperature e.g. an MHI batch furnace fitted with a DRO e.g. for old spent dross one could use:

| H14BLE 15 x 15 | 1400°C (2552°F Max) | 15″H x 15″W x 15″D https://mhi-inc.com/PG4/bottom-loading-furnace.html#t-1 |

In such a furnace a Kg 25 Kg crucible batch can be melted in about 2- 4hrs (depending on crucible temperature). So over a period of a day or so of continuous use 10 loads of 20-25 Kg equaling 250 kg can be melted and transferred to a holding furnace which could have a DRO attached if required.

The DRO provides a very useful ionic cover when used continuously over existing melting furnaces. THE DRO is not the right equipment like a high-temperature furnace for oxide melting. The batch furnace above costs about 40 K FOB without any crucible handling devices (i.e. good for about 25 Kg crucible). Once a crucible load is melted, it can be transferred to a 250 Kg holding furnace with the DRO fitted on it if required.

So in summary. The DRO is a very useful add-on to an existing furnace and liquid-holding and melting furnaces. To melt chips and dross, and affect an economic recovery it is perhaps best to melt in a smaller but very high-temperature furnace with hard refractories.

Electric melting

It is clearly noted from the chart above that electric heating is the most efficient and clean method of heating. The following is adapted from an EPRI report on electric heating. Melting, using electric resistance heating (radiation heating to the crucible), can be a low-cost choice, as well as provide complete freedom from the noise and excessive heat of combustion processes. This simplistic heating method also results in a high-quality melt with low oxidation losses. Resistance furnaces are often suitable for smaller melting facilities where investment funds are limited and high production rates are not necessary. Production electric resistance melting furnaces are available in a range of sizes from 100 lb. capacity to custom-designed furnaces in excess of 20 tons. Crucible furnaces are generally used in the 250 to 2500 lb. range, while reverberatory furnaces are suited for higher production requirements.

In normal electric heating, conduction through the walls of the crucible ultimately melts its contents. The walls of the crucible are heated radiatively. This is normally efficient for copper and steel which melt at high temperatures but is not as efficient for aluminum or zinc. Notwithstanding this issue, the efficiency is high because using such a construction, there is little heat loss due to convection or radiation to the outside. Using resistance elements for heating results in reasonable uniformity and control than is often possible with gas burners. However indirect gas burners give better uniformity at low temperatures (such as that used for aluminum). This uniformity impacts crucible life. The advent of the PAM furnace has shown to give the best of all systems i.e. take advantage of electric heating efficiencies and control and utilize the same for the benefits of convection heating which is available from combustion systems.

Such furnaces are often of the reverberatory type. Reverberatory furnaces are normally used for continuous melting operations. The wet-bath reverberatory furnace is one of the most popular systems for melting aluminum. With this type of furnace, raw materials are introduced at a charging well into a molten bath at one end of the furnace. The center holding portion of the furnace is sealed off from the charging and delivery ends by a submerged blade or gate rendering this section isolated and free of turbulence and fluing.

In the case of dry hearth reverberatory furnaces, scrap and/ or ingot is placed in a “dry” sloped hearth where the melted metal continuously runs off into the holding chamber. These furnaces have lost favor, however, due to higher than average metal losses. Basin-type reverberatory furnaces are usually used in foundries with medium to low production levels, and are generally designed for melt loads of 300 to 1000 lb., but can be designed for heat sizes in excess of 20 tons.

The principal advantage of this furnace is the extremely low energy required for holding. For example, to hold 1500 lb. of aluminum at 1380°F requires only 4 to 5 kW compared to 15 to 20 kW for conventional furnaces. When high-capacity furnaces are used, melting can be during off-peak periods and pouring can be during on-peak times.

In radiant rod furnaces, electric currents of 4000 to 5000 amperes are commonly used to heat graphite or silicon carbide resistance elements which radiate to the furnace load and walls (note however as described above such elements are not the most optimal). These furnaces are made to oscillate, thereby facilitating the heat to melt from the furnace walls. Radiant rod furnaces require relatively low investment cost but are primarily being used as holding furnaces.

New Aluminum Industry Developments

Use DRO machines

Use of high-temperature furnaces for scrap

Use of GAXP instead of silicon carbide

Measured Energy Saving

Generally improved even for melting but calculated on basis of Dross Improvements.

Environmental (waste) savings

In addition to this, the DRO-Cascade e-Ion many other non-measurable savings, such as elimination of harmful emissions and noise (no noise), and increase of productivity. One could anticipate that by going electric many of the harmful emissions (e.g. CO, CO2, NOx, etc.) associated with existing gas/oil-fired furnaces will be totally eliminated.

Economic Analysis of Various Types of Furnaces

The factors to be taken into account are: (1) The cost of equipment and installation. (2) Operating costs, which depend on (a) the utility costs in the area (b) The energy efficiency of the equipment chosen (c) The quality requirements of the finished casting (d) The metal losses (dross) to be expected as a result of the melting process. In addition, there is a cost associated with (a) Regulation and comfort factors, such as EPA considerations, heat, noise, and air pollution, and (b) The casting size range and the weight of metal required per day and associated storage and manpower costs.

Installation costs of electric resistance and fossil-fuel-fired furnaces are comparable. It is not practical to hypothesize a specific example, as there are too many possibilities to take into account. In general, fossil-fuel-fired furnaces require fluing, blower equipment, and in some cases heat exchangers (for preheating combustion fuels); however, on balance, power controls often result in a slightly higher investment for electric operations. Another widely used method for melting is the induction furnace. While induction furnaces cost more than resistance furnaces their production rates are generally much higher. An operating cost comparison is presented in this table to illustrate the relative expenses for a hypothetical aluminum melting operation. Metal loss includes dross plus flue loss. The most significant operating cost consideration is not only in the relative cost of the utilities, i.e., gas, oil, electric, etc., but the relative metal losses to be expected and the reliability index. Electric resistance melting yields are high, while metal losses from fossil-fuel operations may be as high as 8 percent. When taking into account the metal loss, the current, as well as the projected metal cost at the spout, should be used in making investment plans. Utility costs vary widely in different localities. For example, gas prices can range from $2.50 to $4.86 per MCF, while electric costs can range from $0.032/kWhr at off-peak times to $0.13/kWhr or more.

Add on benefits in addition to the dross reduction discussed on Plasma products for material processing – One Atmosphere Plasma Beam

Additional Savings:

If you are using an electrical furnace then the 10 Kw delivered by the respective Cascade-e-ion model is also saved in the original furnace energy use as this amount is efficiently added by the cascade e-ion.

| Energy Efficient Device.Power Efficiency Savings: | 1kW | 10kW | 100kW |

| Savings per year: | $876 | $8760 | $87600 |

In the estimates with a 2% dross reduction, the ROI happens within 6 months. Sometimes much faster or slower but this has to be discussed on a case-by-case basis for every use. It is a good deal. A key benefit of using the cascade e-ion plasma source comes from the elimination of nitrogen, argon, or toxic flux covers normally used during the melting of aluminum or silver. The plasma takes air and converts it to a nitrogen ion cover. Many other non-measurable savings, such as elimination of harmful emissions and noise (no noise), and an increase in productivity. Since gas/oil burners are also partially replaced by the Cascade-e-ion we anticipate that the harmful emissions (e.g. CO, CO2, NOx, etc.) associated with existing gas/oil-fired furnaces will be reduced. This is a good benefit. The comparison is shown below which is focused on greenhouse gas reduction. Although this is a complex question and very dependent on the comparison, a general rule of thumb is that 10 kW DRO additions are useful.

General aluminum melt furnace comparisons from published article https://mhi-inc.com/one/heat_transfer.html and http://www.scientific.net/KEM.380.209 and other publications.

|

This is a prototype only. Melting furnace is not for sale, only the Plasma Source and/or the technologies. Please contact us for more details.

Catalog

Conventional furnaces are unable to create heat on the charge and their efficiency falls off. DRO Cascade e-ion assisted furnaces have high power densities and heat transfers directly to the part. Melt rates are estimates that depend on the heat transfer coeffcient and overall power of the melting energy.