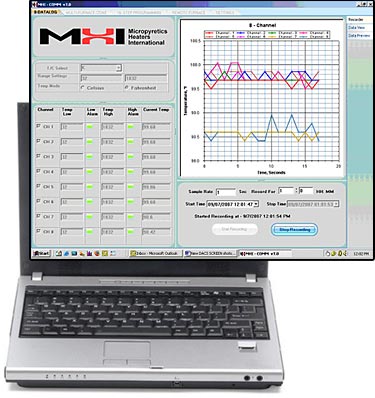

DACS – Data Acquisition Control Software v10.0+ for MHI Furnaces, Airtorch, and other devices

(soon to come GHG and ESG reporting)

“I need my PC to control my process, acquire data, store my results, and graphically present them. I want to complete my projects faster and more efficiently.”

DACS and MHI HMI DACs feature HIPAN, TRIPAN, and XPAN Direct control from the panel on some models, enabling many data acquisition and control platforms. Please contact MHI for DACS.

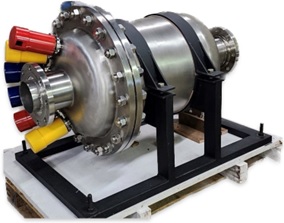

MHI DACS module

MHI DACS is useable only with MHI Control panels with an Ethernet port.

The DACS is a fully programmable Data Acquisition system that lets you control and monitor your furnace from your PC or Laptop.

After being installed/connected, some things you can do from your computer are listed below.

- Log temperature

- Program New Cycles

- Upload programs; remotely execute cycles

- Monitor & record set point, process, and output values

- Monitor temperature settings

- Save your profiles to use at a later time

- You can view and download your data in an Excel table with date, time, sample time, process, set point, and output values.

- The software includes over 70 programs for heat-treating metals, ceramics, and intermetallics.

Plus, there are many more features. Please contact MHI.

*The MHI-DACS will not work with other devices and is not configurable except for an MHI furnace control panel.

The DACS can be purchased for single or multiple MHI furnaces (DACS-S or DACS-M), provided the control panel has an Ethernet Connection.

Ethernet communications with Modbus TCP protocols are used.

Using the MHI Airtorch or MightySteam Communications Package to monitor and report emissions savings.

Contact MHI for emissions reporting for Scope 1 and Scope 3 data.

Features:

- Available as DACS-S single use and DCAS-M-X (multiuse X specifies the allowed number of devices that can be connected. Prices are different for 2 to 6 devices.

- Fully programmable – Mult- program and multi-step programming

- Interface and program your MHI control panel from your PC

- Multi-tab option in multi-use DACS

- Multi-furnace/zone control

- Automatic data logging into Excel file.

- Temperature controls

- Graphical data display

Minimum System Requirements:

Items included with MHI-DACS:

|

Furnace Monitoring  |

|

Display Data Tab  |

|

Multi-step Programming  |

|

|

|