De-e-Ion Zapper machines

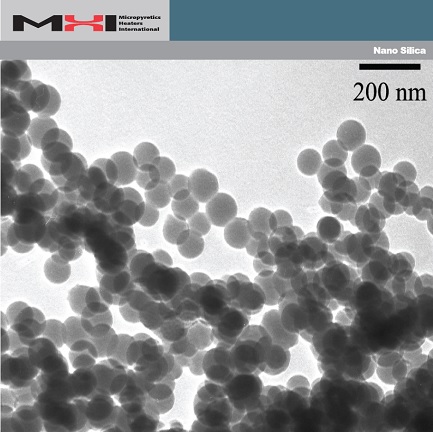

Surface deposit and create graded nano-porous alloy combinations with the Cascade De-e-Ion Machines.

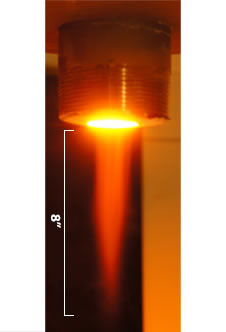

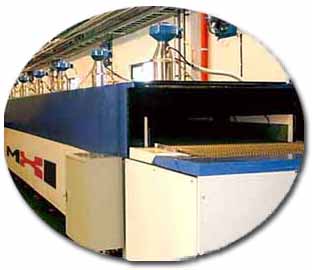

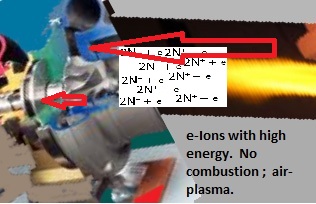

De-e-Ion Zapper machines are employed for surface coatings and for creating unique nanomaterials. Examples of antibacterial coating objectives or special coatings made without vacuum at very high speeds are pictorially shown below in rows 2 and 3.

New ionic low-cost deposition. Minimize pollution and minimize noise – improve energy efficiency.

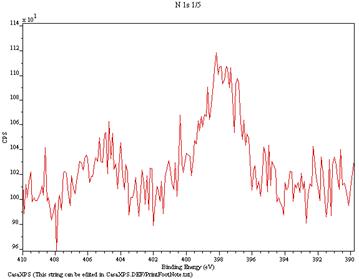

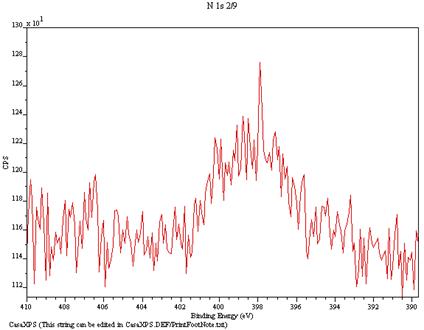

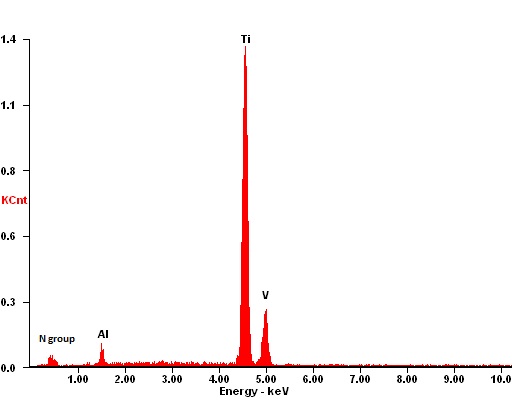

Read about XPS’s results with air and its impact on eliminating corrosion.

View a PowerPoint Presentation

Nitrides, Yittria Zirconia, Boron Carbide, Silicon Carbide, Molybdenum disilicide Oxide. Titanium Nitride (from the air through the cascade e-ion).

|  |  |

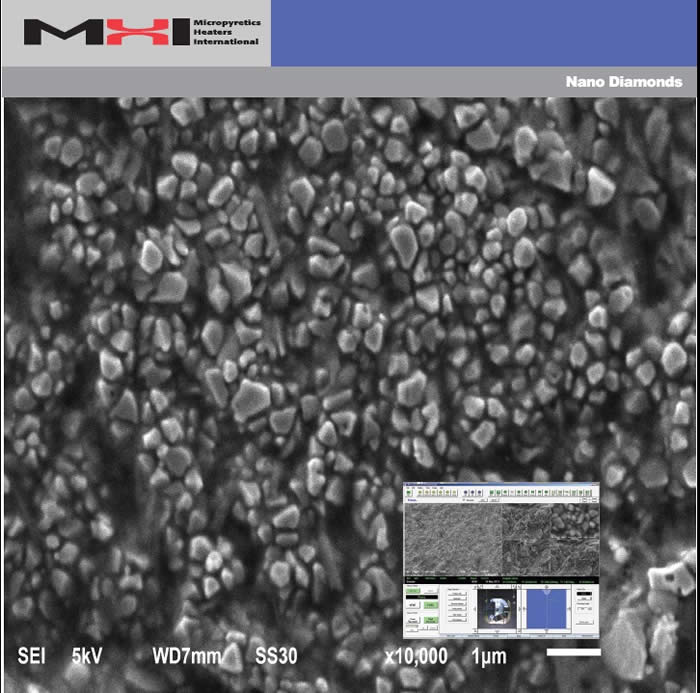

Nitrides, Oxynitrides, Glass, and Nano Surface Depositions. Diamond, Tungsten Carbide, and other high wear-resistant surfaces with the proper texture for tool bits. Tubes and complex shapes. Thick Alumina on Aluminum. Very rapid Molybdenum Oxide on Plastics/polymers for Solar Cells.

Easily make functionally graded coatings and other surface depositions. It is now made simple and scalable.

Continuous HardCoating and Rapid Brazing Practices

Typical Comments:

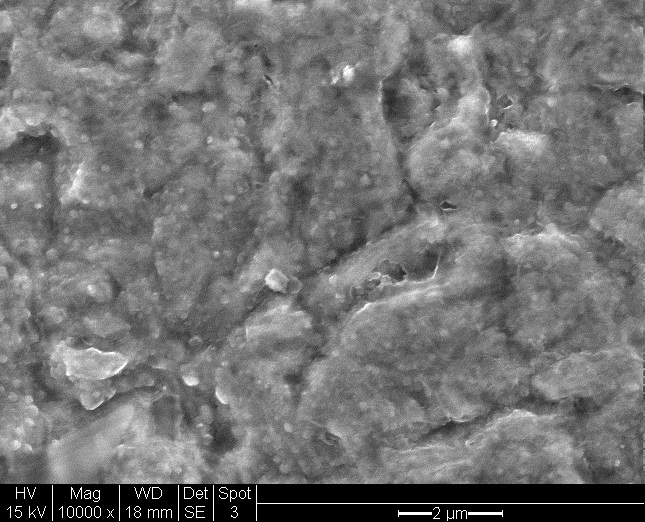

The high-speed, high-temperature ramp is very helpful. As per our discussion with the braze alloy manufacturer, one significant problem often faced is the microstructure coarseness because of many hours at high temperatures (typical to traditional multi-hour furnace brazing cycles). This is the cause for the tungsten carbide particle size to increase during traditional furnace heat-treatment sequences, and then the metallurgical bond integrity reduces drastically. Similarly, any boron carbide particles remain extremely small and well-bonded, as do nano-alumina after the bonding. Rapid heat-up and rapid cool-down are a must for the future.

“One-minute hard-facing operation replaces 48 hr. operations! We also do not need nitrogen or argon atmosphere.”

“What I like about the Cascade e-ion process is that it allows for rapid continuous production instead of batch production.

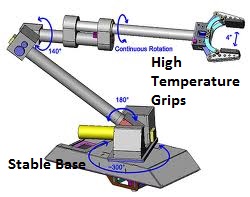

Tool bit bonding by brazing is efficient. With the Cascade e-Ion, the high integrity of the tungsten (carbide) alloy fusion bond with the base steel is very acceptable. When the glue is of such high integrity and tough (i.e., does not activate or allows cracks to propagate), one can quench rapidly after the e-Ion CleanElectricFlame™ exposure.

“I was impressed to see the clean and high integrity interface between WC-Co and stainless steel… .The technology of the e-ion Plasma seems to be great”.

Wear-resistant surfaces may be made within seconds or minutes with e-Ion Plasma by immersing in Plume, representing an increase of several folds in productivity with lower capital cost and operating costs. Below are typical hardfacing interface microstructures obtained with tungsten carbide nano and hardfacing/hard surfacing alloy on a stainless steel substrate.

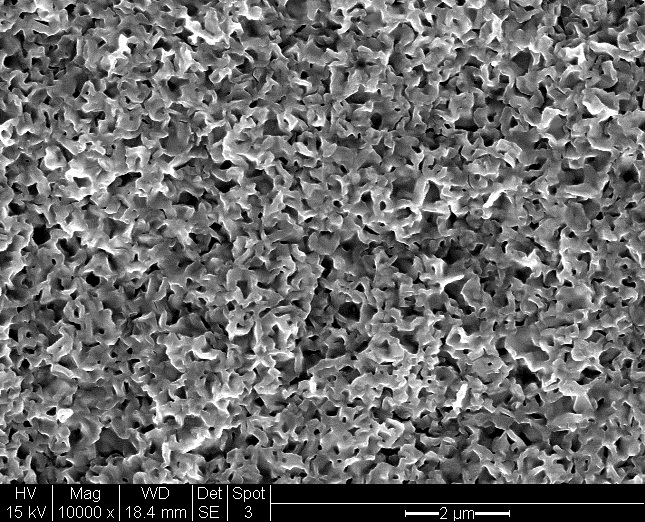

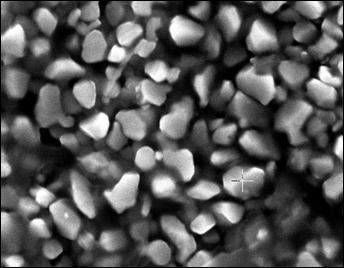

The surfaces below of n-WC were obtained after short exposure to CleanElectricFlame™. Competitive processes are often noted to produce much coarser microstructures. Nano-grained cemented tungsten carbide (n-WC) is currently being researched for many potential applications. The Cascade

E-Ion treated micrographs of n-WC (left) and NiCoMo Hardfacing braze alloy to steel(right).

| Titanium (Ti) brazing early stages of compressor or exhaust | Dissimilar Metal/Ceramic Brazing | Nickel copper 59 Ni |

| New braze compositions | Platinum | Palladium |

| New engine crack repair | Braze Alloy | Au-6 (Gold) |

| Compressor Parts | Hastelloy, Inconel, Waspalloy | Iron Boron Silicon |

| Auxiliary Power Unit (APU) | Implants | Nickel Boron Silicon |

| Fuel systems/compressor inlets | 304 ss or Inconel 600, 625, or RA alloys | Gold 82/Nickel 18 alloy) |

| High compressor and low turbine | Stainless Steel | micro-36-M |

| Fuel systems leak-proof braze | 304 ss or Inconel 600, 625, or 718 | NiCroly Ni-Cr-Al, Ni-Al |

| MRO engine repair hot section/high-pressure turbine. Abradable Tip | Superalloys of Nickel and Cobalt Biomedical Grade alloys | The presented preform, paste, paint (PSP) |

| Fuel systems | Low temp like fuel systems | Silcoro-75 |

| Low-pressure compressor/Ti brazing | Ti-6Al-4V with Mo and other Ti alloys | TiCuNi and Shape Memory Alloys |