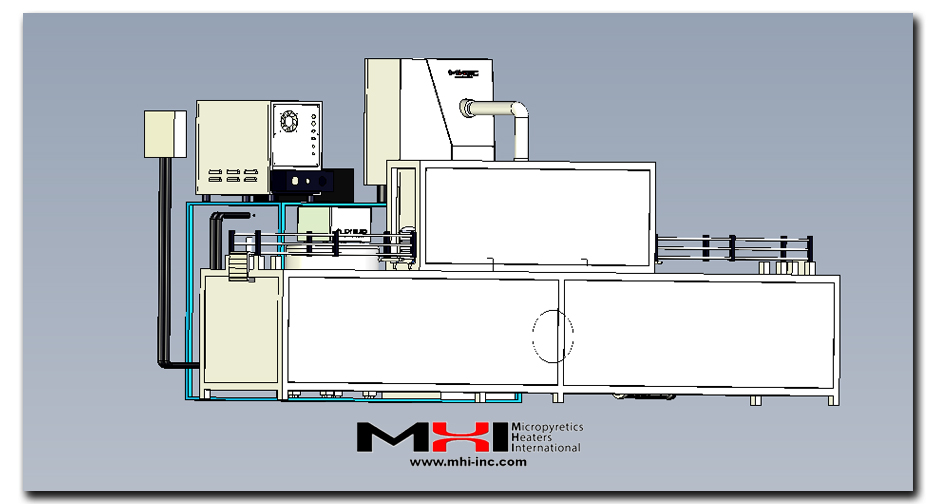

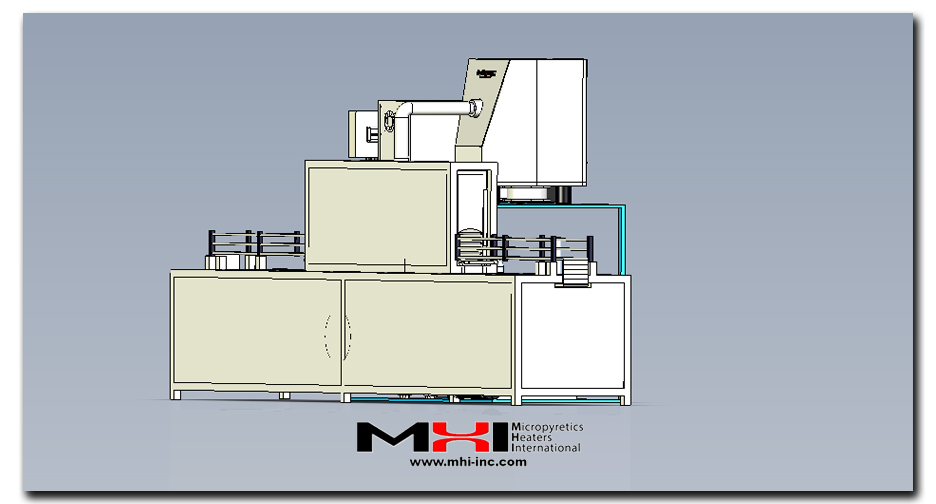

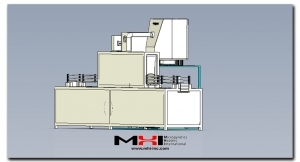

Design with OAB® Steam and Hybrid Tunnels

Tunnel Design from the High-Temperature Leader

For shrink-wrap and other yarns and textiles. Clean at multiple levels, including those for removing bacteria and other small molecules, such as viruses or irritants, by conditioning the cotton and other textiles or yarn fibers. cloth and materials (use the correct residence time).

Feeding into SWE machine. Adding moisture to cotton fiber or for shrink wrap CPG.

Cotton fibers improve their integrity with moisture. The SWE machine with the steam tunnel is easily able to do this.

Save electrical usage. Paying 25¢ per bottle? Check out if the OAB steam tunnel can reduce to 2¢.

For CPG, design for maximum shrinkage with complex bottles. With the suitable materials, ~ 75% shrink in the film can be obtained with OAB steam® and PVC type shrink materials. When placing a wrap over your object, please ensure that the maximum shrink position is not beyond the capability of the wrap (3:1 shrink for PVC or 2:1 shrink for older materials for wraps). Please ensure that the shrinkage is designed to minimize warping (allowing the shrinkage to proceed in a direction that reduces wrinkling).

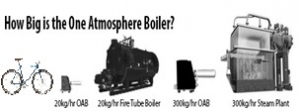

The OAB steam cuts down the number of tunnels required. With the OAB® steam, one has fewer design worries about the number of tunnels as the shrinkage often happens in less than a second. Obtaining energy-efficient equipment has never been easier. Several vendors will sell you tunnels, or you can use MHI designs. With OAB® steam, the steam tunnel generally does not involve jets, nozzles, or design holes inside the tunnel to contend with. The OAB® steam generators may be re-positioned at will.

Cotton fiber improves properties with saturated steam exposure. Please contact MHI to improve energy efficiencies in this sector. Tunnels for cleaning, garments/yarn/fiber, shrink wrap label on bottles, pharma clean tunnels, textiles fiber conditioning. Call MHI for details. MHI results show that OAB® steam produces a tight shrink with less time and a better finish for even the toughest PVC wraps/labels. However, you should always verify such a claim in your specific situation. Turn on and off as required. Belts speeds vary for applications. Please request a sample of the energy and water savings one may expect for standard belt speeds of about 20ft/min, standard bottles (glass included) with a PVC shrink-wrap. Contact MHI.

|  |

We present below a Value Performance Index (VPI) to capture critical performance criteria, both function-related and equipment-related. The complexity of the bottle (material, height, curvature, etc.), the speed of labeling, and the quality of sheen required determine the level of difficulty of the final product/job. If the system that you are considering for purchase can handle a tough shrink wrapping job, higher is the VPI. The versatility of the equipment/system depends on energy efficiency, water efficiency, safety features, flexibility such as portability of equipment, small footprint, ease of designing around the system, and easy on-off on-demand use.

VPI is a semi-quantitative measure that MHI has created. Several variations are feasible in gauging this index, so the user is cautioned to compare this with other indices. The following VPI numbers and assumptions are provided only as a guide.

Are you interested in using a steam tunnel for disinfection or conditioning textiles? Contact MHI.

Purchasing or retrofitting a labeling system should be based on the VPI of a system. For example, if one pays $100,000 for a complete system, one has to maximize the performance index (VPI) in that category. Alternatively, one would choose a less expensive procedure plan with the same VPI. Performance index improves with energy efficiency, scattering (shininess), water efficiency, portability, and smaller footprint. MHI’s OAB® steam systems offer all of these. If you wish to try your shrink wrap with OAB® steam, please get in touch with MHI and provide your sample for your demo or visit MHI and run it yourself. Compare systems with the same VPI.

Typical Value Performance Index Scenarios

| Level of Difficulty* (1-5) | Versatility Rating (1-5) | Example Picture Shapes | Determining factors for the level of difficulty | VPI of the System (Possible scenarios) |

|---|---|---|---|---|

| 5 High |

|  |

| VPI=250 Highest |

| 2 Medium |

|  |

| VPI=100 Medium |

| 1 Low |

|  |

| VPI=10 Lowest |

MHI Bottle 37

Reflection Lengths. A higher number reflects better . Steam makes the surface shiny and for textiles acts in a antimicrobial and better end of fibers – yarn surface tension/energy.

(% Improvement from AVG)

| 73% 61% | 53% 46% 51% 41% | ||

| 57% 50% | 37% | ||

| 45% | 23% | 8% | -40% |

| 33% | 6% 13% | -11% | |

| Average % = Improvement | 42% | ||

The difficulty level increases with the material to be labeled (glass over plastic), type of base-lip, number and shrink percentage of contours, concavity, convexity curvature, how far they are spaced, etc. Depending on the load, the common belt speed is 10ft/min-400ft/Min. The performance expectation increases with energy savings demanded over conventional systems (say 85% saving in energy and water) and speed requirements (say 200 feet per minute per 10 kW per object compared to 20 feet per minute per 300kW per object). Versatility rating is the highest at 5. Flexibility, for example, can be high if the steam generator can be turned on off on demand, if the steam generator needs to be easily relocated, or allows the mix and match bottles in the same run. Flexibility can also increase with the simplicity of design, where special tunnel technology with jets and so on is not required. For SW OAB® systems, the assumptions for the table above are that they have a high (4 – 5) versatility rating compared to a 300 kW pressure boiler steam which is given a versatility rating assumption of only 2.

From MHI, free help with sourcing film (wrap) and highly reduced machinery set-up when you switch to the extremely energy efficient are available with the much lower price OAB® steam generators. Free help with financing – even outside the USA, where feasible.

Want to find out how MHI can help you meet your steam needs? Fill out a quick questioner and we will help find a solution to meet your needs.