Description

Specifications:Steam Superheater-1kW- INL for Dry Hot Steam | |

| Model: | Dry Steam Superheater-1kW- INL (110V, 1kW) Dry steam (no water mist/droplets) heater only. The dry steam (~2 kg/hr) input of 100C (full quality steam) will produce a steam output of about ~500C. Only dry steam can be used. Not for wet steam. For wet steam, please get in touch with MHI. Unit sold as is where is – no returns. Not rated for Air.

|

| Dimensions: | Unit: 1.5″ dia x 15.25″ L (collar is ~1.95″ dia) Inlet: 1/4″ NPT male fitting |

| Weight: | Lightweight with a compact, ergonomic design |

| Temperature: | For steam the maximim ouput is 500C. |

| Airflow: | Steam max is 2 kg/hr dry gas. |

| Voltage: | 110/120 VAC |

| Frequency: | 50/60 HZ |

| Current: | Approx. 9 Amps @ 110VAC for 1000Watts |

| Power Consumption: | ~1000 Watts |

| Output Power Control: | When a BPAN-O-PLUS is used |

| Handle: | None. |

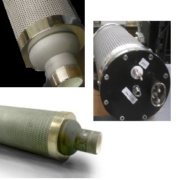

| Optional Accessories: BPAN-O-PLUS and TC REad (Pictures shown above) | Note the unit has its thermocouple. Power controller BPAN-O-PLUS (120V) is an option for power control. This interfaces with the built-in thermocouple. The TC read purchase includes an additional K- thermocouple and its stand (TC Read+TC+STAND) or can be used with the BPAN-O-PLUS power controller. The built-in thermocouple can also be connected to the optional TC Read system for an external display. The TC-Read unit plugs into a 115/120V single-phase socket. Optional: 3 1/2″ LCD display switchable between °C and °F (TC Read) |

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA MHI Inc

MHI Inc