Description

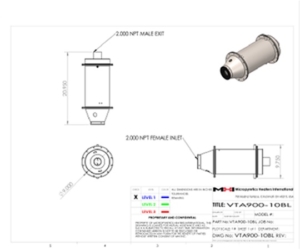

Model No: VTA900-10BL

This 10KW VTA/MTA class gas electric heater can be used to heat Air, Nitrogen, Inert Gases, and CO2. The exit at 10 KW power can be between 40°C – 900°C. VTA units can be used with blowers. The pressure drop is less than ~0.3 psi for up to 750C exit temperature. The XPAN is recommended for use temperatures above 700C.

Please check with MHI prior to purchase as the pressure drops and maximum temperature depends on the gas and type of use.

The unit is a two-body flange model (see picture below). The special sale price is only valid while the stock lasts. Several types of optional electrical XPAN control panels are offered.

PLEASE CHOOSE THE SEALED FEEDTROUGH OPTION if a high degree of sealing is required and for MHI internal test at 2 Bar.

Pictures below show units with and without the optional sealed Feed-throughs

Plug in for any single-phase voltage 208V to 240V (see below for the maximum delivered power for each supply). Not for use beyond 240V single phase supply. Minimum supply is 208V single phase

Stainless steel construction for low distortion.

Use with voltages 208/220V /230V/240V.

The maximum power is 10kW 50/60Hz for a 240V electric supply.

The maximum power is 9kW 50/60Hz for a 208V electric supply.

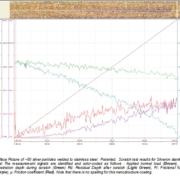

For air: The flow is ~34 SCFM at 900°F (500 °C), 75 SCFM at 500°F, or close to ~ 100 SCFM for 390°F with a 0.2″ psi pressure drop. The pressure drop is less than ~0.3 psi for up to 750 °C exit temperature. For higher temperatures, use about ~25 SCFM for 900 °C with 0 45″ psi pressure drop. Above 700C, compressed air flow input is preferable as common blowers are not always reliable for overcoming the drop in pressure for this unit.

Note that the inlet region (the top entry) may change in dimensions if the sealed feed-troughs option is elected.

Temperature: Maximum 900°C for continuous Air, About 850C for CO2. Typical use output ~ (40- 900°C). Control the temperatures with flow or power variations. Power can be adjusted on the optional XPAN control panel. If a control panel is purchased, flow temperature can be adjusted with flow rate (user scope), power, or temperature settings.

Unit Description: Custom VTA/MTA Airtorch® Heavy Duty Industrial Air Heater

Outlet 2″ NPT. Inlet 2″ NPT female (see product images). The picture shown may be illustrative only.

Inlet 2″ FNPT.

The unit shown in the photograph fits a 9″ Diameter (at flange) and 22″ Long envelope.

Pictures also show outlet and inlet, power chords, and T/C wires. The XPAN is offered with an optional UL 508A rating and with an optional stand. Please choose this in the pull down menu.

Note that the unit is a plugin with a minimum flow required when energized .

Lower temperatures are obtained by flowing a higher gas amount than the minimum required or using the HIPAN/XPAN control temperature and power control panel to control both temperature and power. The XPAN panel has a phase angle SCR and other features such as an ethernet port.

Not rated for hot gas input beyond 70°C. Not rated for wet input. Note: Parts of the surface are hotter than 50°C during use. This Airtorch® has a Type “K” thermocouple installed as a standard; an over-temperature T/C is provided as an option when supplied with an electrical control panel unit.

Unit Features:

- Stainless Steel Shell Construction

- Double flange model.’

- The unit is not rated for pressure.

- Built-in Type K Thermocouple (OTC offered with XPAN)

- Lightweight with a compact, ergonomic design

- 208/220 or 230/240V plugin design

- Rapid heat-up

- Compressed air/gas compatible

- Inlet gas not to exceed 70°C (can be increased to 100°C with the sealed feedthrough option)

- Outlet 2″ NPT.

- Inlet 2″ FNPT.

- 1 Bar use. Please choose the feedthrough option if a sealed unit is required. When this option is selected, MHI provides a 2 Bar internal pressure test certificate for the unit.

- 208-240V 50/60Hz (Single phase). The Wall socket must be able to provide 10 KW to the device. 240V is required for the highest temperature. Please follow local electrical codes.

Specs:

- Air Inlet: Compressed Air or Gas (DO NOT USE COMBUSTIBLE GASES) Air Outlet 2″ NPT fitting.

- Weight: Lightweight with a compact, ergonomic design

- Temperature: Maximum 1000°C continuous. MHI controls are recommended if used close to the maximum temperature.

- Voltage: 208/220/230/240VAC Frequency: 50/60 HZ. The picture shown above is the approximate unit. It fits a 9″Diameter envelope (at flange) and a 22″ Long envelope.

- Power Consumption: ~ 10 Kilowatts Output Nominal@240V. It may be used as a 208V, 220V, or 230V plugin. The power is slightly lower at 208V.

- Power Control: The optional control panel allows you to change the airflow or the output power, varying the output temperature.

- Optional: XPAN™ is required if power and temperature control options are needed. Please contact MHI.

- Flowmeter not included. Fan not included.

- Standard Accessories:

- Display – Not included- optional

- Built-in Thermocouple can be linked for external display.

The units as offered are for atmospheric use. However for up to 2 Bar – use the option to upgrade the feed-throughs. When chosen a MHI pressure test certificate is included. Control panels that provide a feedback control are highly recommended although the unit can plug into a single phase volts (208 to 240 V). The 240V single phase supply is required for 10 kW. For users who want power adjustment along with temperature control adjustment or wish to use at a lower than the maximum power, an XPAN Control Panel 208V/220V/240V is recommended. Generally, when operating close to the maximum rated temperature, it is advisable to use SCR-based controls with a rapid Overtemperature cut-off T/C (thermocouple) and the process T/C. These are available in the XPAN panels. MHI can provide this extra T/C. Please select the options menu.The units plug into the 208/230/240 V plugin as long as the minimum flow of about ~25-28 SCFM is maintained and the unit flow does not exceed the rated temperature. Please contact MHI at 513-772-0404 for electrical control panel quotes or use the pull-down menu above for standard panels.

For details about the HIPAN/XPAN Control Panel, please click here.

MHI Inc

MHI Inc MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA

MHI Inc. USA