Cascade e-Ion Zapper™ (EIZ) Furnace

About the Cascade e-Ion Zapper™

In addition to the basic Models (View PowerPoint Presentation), the EIZ includes thermal extenders like RRs and Thermoplates. Special pricing is provided with these time-tested MHI thermal products.

The Cascade e-Ion Zapper™ (EIZ) Furnace uses a scalable CleanElectricFlame™ technology platform to provide non-contact, continuous heating with accurate temperature control in a compact, versatile design. The Cascade e-Ion ZapperTM Furnace Category allows for processes to be completed while cable or wire moves through the furnace typically and in line with Plasma.

The Cascade e-Ion Zapper™ Furnaces can deliver the rapid heat rate needed for RTP, melting, brazing, and heat treating. The Cascade e-Ion Zapper™ is ideal for hardening applications with extremely small HAZ because it allows for a lower residence time than traditional heating methods such as induction. The Cascade e-Ion Zapper™ allows for rapid air processing and several other gases. Hardening is also caused by oxynitrides development.

Processes can be completed while wire or cable moves through the e-Ion Plasma™ environment. This type of heating provides the rapid high temperatures necessary to melt and heat treat. E-Ion devices feature higher heat-up rates compared to competitors. The Cascade e-Ion Zapper™ Furnace allows for easy manipulation of parts, all within 15kW of power. Compare the Cascade e-Ion Zapper™ Furnace to existing technologies, and you’ll quickly see how a Cascade e-Ion Zapper™ Furnace can reduce costs and improve efficiency.

Not sure if the Cascade e-Ion Plasma™ is suitable for your application? Contact MHI.

Cascade e-Ion Zapper™ (EIZ) Furnace Specifications

| e-Ion Zapper™ Furnace |

| Up to 200°K/s Heat-up Rate Possibilities. EIZ extenders can enhance even this heating rate. |

| 9-17kW Power Consumption (Depending on Configuration) |

| Highly Modular |

| Compact Table Top Sized |

| Highly Accurate Controls |

| No Water Cooling Required |

| Ability to Treat Ungrounded Metals |

| Stainless Steel Construction, Integrated Fan |

| No Toxic Emissions or Combustion Residues |

| 220/230/240 Input Voltages |

| Single Phase or 3 Phase |

| Near Silent Operation |

| Plume Properties Recombination Temperature ~2500°K Convective Plasma (variable gas temperature is up to 1600°K) Heat Transfer Coefficient ~225W/m^2.K.(Compare to 10W/m^2.K) |

| Example of Plasma Formation – N2+E ->N2++ e or 2N+E -> 2N+ +2e Example of Plasma Recombination – 2N+ + 2e -> 2N + E or 2N -> N2 + EPossible species include O2, N2, O2+ , N2+ , N, O, N+, O+, e−, in e-Ion Plasma of air Possible species include N2, N2+ , N+, e− in the e-Ion Plasma of nitrogen. Almost all commonly employed elemental or molecular gasses/species can be ionized, including Ar, Xe, H2O, etc. |

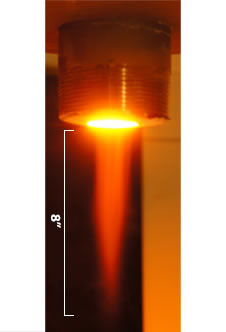

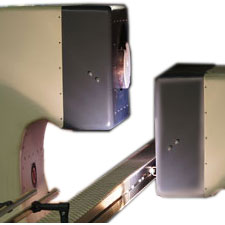

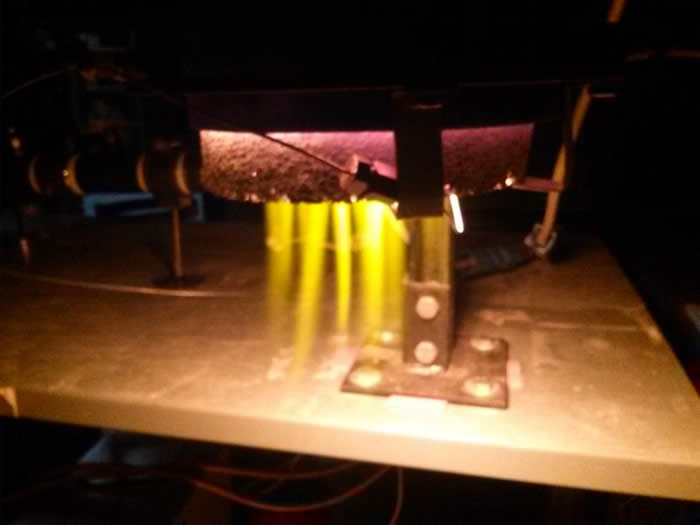

Cascade e-Ion Zapper™ Photos

Cascade e-Ion Zapper™ Furnace with RR extension

Cascade e-Ion Zapper™ Furnace with a RR extension

Features

The e-Ion Zapper™ Furnace is designed for quick heat-up applications at very high temperatures, from simple heat treatment to complicated electronics and materials processing profiles. The e-Ion Zapper™ Furnace offers high temperature uniformity and an unmatched rapid heat-up rate of 2high-temperatureeating rate obtained from time to melt tests.)

| Features |

| The cascade e-Ion Zapper™ Furnace features a highly uniform temperature zone appropriate for the custom modification. |

| Eurotherm process controller can run up to 20 programs with 16 segments per program. |

| Ethernet or RS 232/485 communications options are available to connect to the PC. New Dacs 2 with USB. |

| Power controller featuring double back-to-back phase angle fired SCRs, with current limit, adjustable soft start, and quick response to the control signal. |

| It is equipped with over-temperature control through an independent thermocouple to monitor overheating. |

| Up to eight thermocouples are used to monitor temperature at different locations. |

The XPAN™ control panel rests inside a NEMA enclosure that meets NEC and NFPA requirements for safety and reliability.

*SDPM position (custom orders only) controller handles up to 10 programs with an unlimited number of steps, time delays, and repetitions. The programmer has a non-volatile memory of 32 KB for over 100,000 hours. The computer interface control system has complete DDE dynamic data exchange by SCADA/Windows software, which provides nine simultaneous communication ports.

Vacuum and atmosphere attachments are available. The Plasma creates a clean environment in the air.

Cascade e-Ion Plasma™ Applications

Zapper™ Systems provide non-contact, continuous heating with accurate temperature control in compact, versatile designs. The e-Ion Zapper™ system can provide normalizing, stress relieving, annealing, hardening, curing, surface melting, and coating for knife-edge, wire, and cable applications. Processes may be completed while wire or cable moves through the e-Ion Plasma™ environment. This type of heating provides the rapid high-temperature heating necessary for melting and heat treatment.

e-Ion Zapper Applications

Our unique e-Ion Plasma™ features novel technology that replaces existing processes while improving efficiency and productivity—Immerse in CleanElectricFlame™ for non-line-of-sight processing or BendHeat™ requirements.

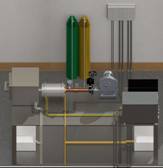

Cascade e-Ion Zapper™ Furnace Models

| Cascade e-Ion Zapper™ Furnace | ||

| EIZ for deposition and extremely rapid heating with RR | 208/220/230/240 | 10-20 |

| EIZ-C – Custom Brazing, Hardening, and Heat-treating Applications | 208/220/230/240 | 9-30 kW |

Cascade e-Ion systems allow continuous sintering (3Dsintering™) or hardfacing without hydrogen. All ionic gasses are of a reducing kind.

Plasma polymerization of many unique polymers and blends and their surface deposits remain unexplored with this new method.