High Temperature Microtube™ Heaters

| Microtube™ Heaters | |||

Part # THM200-MicrotubeMax Temperature* ~ 1700°C. Power 250 Watts. Thermocouple Included. Stand Included | Part # THM500-MicrotubeMax Temperature* ~ 1700°C. High Power 500 Watts. Thermocouple Included. | ||

|

| ||

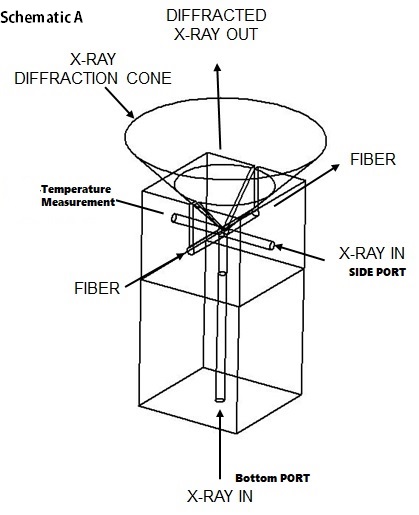

General Purpose Multi-Axis Stand for Microtube Heaters, including for X-Ray UnitsThe stand-holder assembly may be rotated for horizontal or vertical use. X-Ray capable units. Please Click here. | ||

1200C | ||

Microtube and Tube Furnace Applications

Because of their versatility, MHI’s furnaces allow for several uses.

Because each application is unique, Please Contact MHI to discuss which product best fits your needs.

| MicroTube Furnace and Large Tube Furnaces Common Uses in Optoelectronics and Materials Processing | |

| Nano-Diamond Production Gas (%CO2 ~0.4%, %H2O~ 0.5 to 0.9, %CO~20.5 to 20%, 42%-N2, H2~36 %, Rest CH4- call) http://waveguide/wastes/nonhaz/industrial/special/mining/minedock/id/id4-pla.pdf | Reaction Furnaces Recycle Commodity Noble Metals For Palladium and Platinum Production. Recycle from dross/cake sponge. |

| Attach to the steam generator (end caps required). | Attach to gas input (end caps required). Use SIMGAS. |

| Measure spectral intensities, emission and absorption, and line broadening with temperature. Use in optoelectronics and biomaterials. | See information on general furnaces. |

| Drying, Brazing, Vacuum, and Inert. Save substantially. Contact MHI for a per load ROI estimator and methods to do quick loads. | Gas Processing and Powder Production |

| Melting and Powder Sintering and Powder Production | Sintering, Oxidation, Perovskites. Add OAB steam. |

| Industrial Processes for Energy, including Thermal Membranes | Tempering, Austempering, and Martempering without large graphite furnaces (the new modern way) |

| Gas Preheating, Hydrogen Gas Heating. | Annealing, Coloring, Heat treatment. |

| Materials Testing, Creep, Fatigue, High-Temperature Wear. Lubrication. | Metallurgy. Use for palladium refining to dross separation techniques for aluminum. |

| General Heat Treatment. | Custom Applications. |

| Industrial Processes for Syngas, Biomass, Biogas, H2, CO2 for H2 supply, electricity generation, CHP-sawdust, paper waste, switchgrass. | Gas Processing, Hydrogen Pyrolysis, Cellulosic Biomass to Hydrogen Pyrolysis, Gasifier Ag-forest residues, Wood chips, Sawdust, Paper Waste, Energy Crops – switchgrass, miscanthus, or biomass crops. Start even with 40-55% moisture, process gasify cellulose, hemicelluloses, and lignins. |

| MicroTube RR Type | MicroTube RR Type |

Part # MRCL-GA1125-6- Microtube Max Temperature* ~ 1300°C. High Power 825 Watts. Thermocouple Included. | Part # RHUL-MP1125-6- Microtube Max Temperature* ~ 1550°C. High Power 1000 Watts. Thermocouple Included. |

|

|