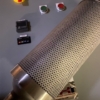

HGA-M-04 Superheated Steam/Air/Gas Generator (4KW)

$8,200.00

Description

The HGA-M-04 is a unique device that provides low to high-humidity air or steam mixture gases like steam containing CO2, N2, Ar, and He mixture with H2O content. The maximum power is 4KW for this unit. A high-temperature superheated mix of steam-air or steam-gas output. Note that the parameters for air and steam are given in the Unit Features tab. The unit allows an adjustable humidity or air-steam mixture control (the two pumps (offered on the site in the pull-down choice menu) are required for control along with the air flowmeter.

The high-humidity steam/air mixtures will have varying temperatures depending on the mix. Please review the unit features in the adjacent tab.

Superheated steam is an odorless, high-temperature gas (not to be confused with hot water mist). OPUMP-1 (water pump) is a highly recommended option for metering the water flow. Several other options are available and recommended. The airflow control option (flow meter) is generally required to control the airflow. The A-pump (air pump) can provide continuous airflow within the product specifications and permissible use.

The BPAN-O-PLUS option is required when power adjustments are contemplated. If the power controller is not purchased, please ensure minimum air and water flow are present to prevent burnout.

Voltage: 240 VAC. Please indicate the request on the pull-down menu in the selected options.

Current: Approx. 18 Amps @ 240VAC

Power Consumption: ~4000 Watts with 240V. Lower with 208Volts. Single-phase power supply required.

The size envelope is approximately as follows:

Dimensions are about 18″ long and 5.5″ in diameter.

Exit: Threaded exit nozzle 2″ NPT Male, for steam/gas mixture

Inlet: Threaded inlet nozzle 1/2″ NPT Male, for gas

Safety precautions must be taken when dealing with hot gasses, including steam.

Safety: PLEASE DO NOT USE UNIT ON COMBUSTIBLE LIQUIDS. THE DANGER OF SUPERHEATED STEAM SHOULD BE WELL UNDERSTOOD. PLEASE WEAR GLOVES, GLASSES AND A HARD HAT. PROTECTIVE CLOTHING IS REQUIRED. STEAM CAN PENETRATE CLOTHES. Patents applied and pending.

Installation: The user is responsible for installing and using the product according to the instruction manual. The airflow generator is also within the user’s scope unless the A-Pump is purchased.

Options: A control thermocouple for the hot air generator part is included. An electrical 240V 50/60Hz supply is required for this unit. 4 KW system requires compressed gas from any source, including the A-Pump as air input. Compressed gas is user scope. If using a different gas than air, only noncombustible gases are allowed. Common ones are N2 or insert gases. The supply of such gases is within the user’s scope.

Picture of TC, TC Extension Wire, and Stand in Packaging.

Typical Use: High-temperature and high-humidity steam is used in applications such as antimicrobial, soil, ceramic drying, and sanitation. It is also used for process simulation.

For NeverDown(TM) unit -replacements, please contact MHI at [email protected] at 513-772-0404 with the serial number.

Please click the specifications tab for a typically expected performance at a known setting. Not all the setting widows for power mixture and temperature are known.

If the BPAN-O-PLUS power controller is not purchased, maximum power will require a minimum of 9 to 10 SCFM Airflow or N2 flow.

The temperature is controlled by water flow, airflow (user scope or choose the A-pump from pull-down options), and power controller (if purchased from pull-down menu options).

A DACS-A Datalogger (software + hardware) is offered and can be used with the BPAN-O-PLUS system. This logger can be used to download and plot the temperature vs time data.

Potential uses: For drying, cleaning, layering, epoxy drying and other film uses where superheated steam is required at one atmospheric pressure. Ideal for steam drying or steam oxidation. Product has uses in surface technologies, cleaning technologies, drying technologies, curing technologies, nano technologies. Attempt use also for precipitating crystals of several small sizes including nano crystals from solutions. Precipitation droplet sizes may be controlled by controlling rate of cooling, impingement conditions and type of surface.

High Humidity Control: Steam temperature and the relative mass of moisture in steam-air mixture (specific humidity) depends on water valve setting and air inflow setting. This unique device can give more than 40% specific humidity at temperatures greater than 100C (compare with a specific humidity of less than 3% in fully saturated air at room temperature i.e. air with RH=100%).

Typical settings: This unit requires a compressed air source and a metered water pump like the O-Pump-1. Setting:

(Full power of 4 kW):

- Please note that the dimensions of the control panel will differ for specific panel ratings for cUL and others.

At 8 SCFM Air or Nitrogen and 0 g/min water, the exit temperature is ~850C. These are approximate values.

At 8 SCFM Air or Nitrogen and 9g/min water, the exit temperature is ~600C. These are approximate values.

At 8 SCFM Air or Nitrogen and 14g/min water, the exit temperature is ~720C. These are approximate values.

At 8 SCFM Air or Nitrogen and 40g/min water, the exit temperature is ~400C. These are approximate values.

The user is required to provide an airflow device from a compressor or gas bottle and regulate the flow with a flowmeter.

The unit comes with a manual that has comprehensive valve setting data for the water (manual available only with purchase). These settings may vary with use and other conditions. The values above should be considered approximate. Your results may vary with the unit and the type of use.

Options: The Control Thermocouple for the hot air generator part is included. The steam output temperature depends on the amount of steam and could be up to 600C. The unit requires 10 SCFM air. Thermocouples and brackets are sold separately, or users may provide their own. An Electrical 240 50/60Hz supply is required for this unit. The 4 KW system requires compressed air input.

OPUMP 1 Specifications

- The water inlet pipe is 1/8”. It is provided with a pump.

- Settings from 8 ml/min to 100 ml/min.

- 120V 50/60Hz

- Size envelope is 6”(D) x 6”(W) x3”(H)

- Weight is ~700gms

BPAN-O-PLUS Specifications

- BPAN-O models have a UL microprocessor (PID) programmable controller (An over-temperature controller included in all BPAN-O-PLUS models)

- Best soft start and current limit included

- Over-temperature controller available in BPAN-O-PLUS

- Durable enclosure for Models (weight is approx. 14 kg for models)

- Optional: As quoted, digital communications RS232/485 120V and 220V/ models.

- 220V Bpan models up to 6-8 KW. The 120V models up to 1.5KW.

- Fan or power controller in some models

- SCR power controller with current limiter (extended soft start). Please call for details

- Plug-and-play Data Acquisition System (optional) – MHI DACS

- Remote on/off (optional)

- BPAN Dimension: 8 1/2” (H) x 12 ¼”(D) x 19 7/8”(W) (Includes Conduit Connector Extender in the depth dimension).

- Please note that the dimensions will differ for specific panel ratings for cUL and others.

At 8 SCFM Air or Nitrogen and 0 g/min water, the exit temperature is ~850C. These are approximate values.

At 8 SCFM Air or Nitrogen and 29g/min water, the exit temperature is ~600C. These are approximate values.

At 8 SCFM Air or Nitrogen and 14g/min water, the exit temperature is ~720C. These are approximate values.

At 7 SCFM Air or Nitrogen and 40g/min water, the exit temperature is ~400C (BPAN-O-PLUS required for this setting). These are approximate values.

Q: When do you dry with steam instead of drying with hot air?

A: There are many benefits to using steam but the main one is the availability of a gas with a lot of stored enthalpy at a lower temperature than corresponding dry air with the same enthalpy. So if you were interested in drying paper which has an ignition temperature of say 450°F, then the use of superheated steam at a much lower temperature may produce the same drying efficiency as hot air at a high-temperature which could be in excess of the paper ignition temperature.

Q: Is steam drying energy efficient? Is it better?

A: The answer is YES in many applications. Compared to boiling in hot water to remove dirt, superheated steam is faster and may not require the subsequent drying operation thus saving you time and money. There is also the possibility that because of the large enthalpy content and higher than 100C steam temperature, the cleaning could be more efficient, reach tough to clean spots, and eliminate more.

Patents applied and pending.

Detailed installation and use manual provided with product.

Some lead time, about 3 to 4 weeks, on this product may be encountered because of the high demand.

Control thermocouple for the hot air generator part is included. Steam output temperature thermocouple and bracket is sold separately or user may provide their own on their part. Electrical 110-120V 50/60Hz supply required for this unit. This 1KW system requires compressed air input and water input.

Steam Products

J.K., One of the largest US Company for CPG and health care goods

Worked beautifully – … Thanks.

J.M, Billion Dollar US Company

“I have finally had a chance to work with the heater (steamer); it is performing fairly well.”

Buyer at large World AE company.” I personally ….. love to have you as our supplier……”

J.B., Major US University

“… he was a great help and recommended the HGS product line.”

M.W., Major US University

Ours (HGA-S) seems to be working fine ….

F. ., Major Canadian University

Hello … I ran the steam generator and the CX1300 unit this afternoon…………….. the CX1300, both pieces of equipment worked well. Thanks for the pdf on the controllers. Now that I know that everything is working, please tell……..that I will forward him some pictures of my modifications.

S Compnay, U.K.

…We used the HGA2 as a research and development tool for our surgical devices. The HGA2 steam device performed well for us. It was used up to heat various plastics and materials up to 400°C with steam.”

Robust Radiator™

M.O., National Laboratory

“…the heating system that you helped me set up is working great!”

E.B., University

“…Robust Radiator is working perfect as a Crucible heater.”

L.C., Canada

“We just received the elements … they look great.”

Dave J, Washington

“I am very pleased with its performance. We feel it can be useful for a lot of our projects.”

See use picture.

MHI Inc. USA

MHI Inc. USA MHI Inc. USA

MHI Inc. USA

MHI Inc

MHI Inc

MHI Inc. USA

MHI Inc. USA